Patents

Literature

46results about How to "Fully and evenly supported" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

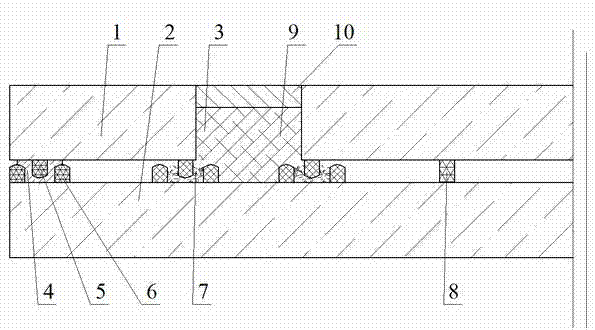

Vacuum glass laminated at high temperature and production method thereof

InactiveCN104743842AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingHeating furnace

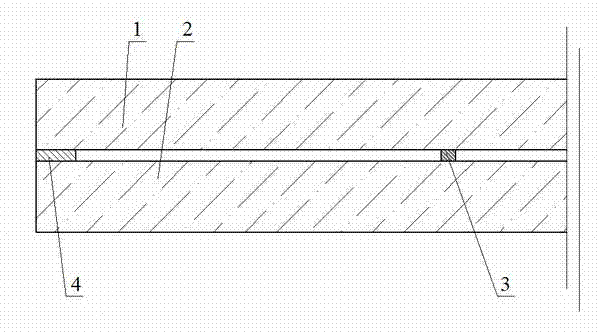

The invention relates to a vacuum glass laminated at high temperature, which comprises an upper glass and a lower glass, the upper glass and the lower glass are plane glass or convex glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder or a metal solder in a vacuum furnace, an enclosing vacuum layer is formed between the upper glass and the lower glass, and the supporters with lattice arrangement are arranged in the vacuum layer. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and usage life is increased.

Owner:戴长虹

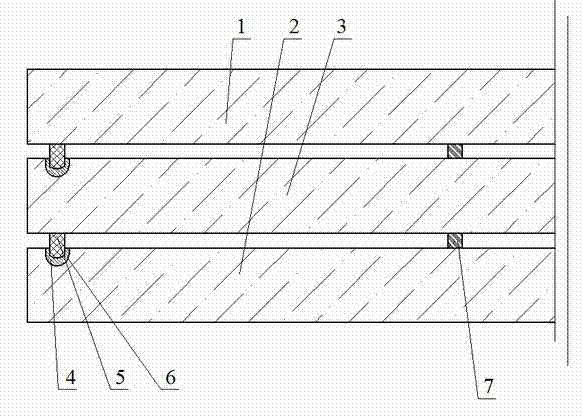

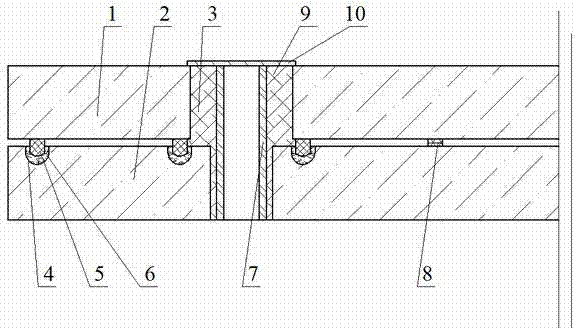

Metal-welded plain vacuum glass provided with edges sealed by sealing strips and manufacturing method thereof

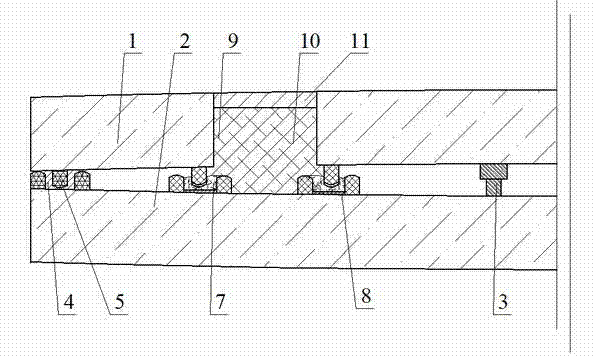

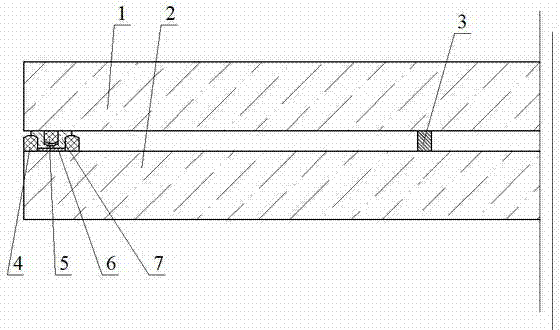

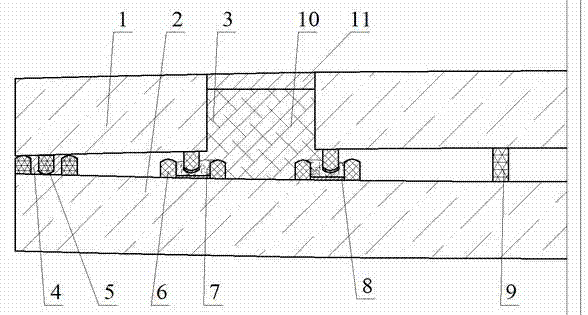

Metal-welded plain vacuum glass provided with edges sealed by sealing strips is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the upper glass is provided with at least one sealing strip; the periphery of the lower glass is provided with at least two sealing strips; the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; and after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by metal solder in a vacuum furnace. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing grooves and sealing strips and manufacturing method thereof

InactiveCN104743805AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingConvex side

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing grooves and sealing strips is disclosed. The convex vacuum glass comprises upper glass and lower glass which are convex glass. The upper glass is provided with one to four air extracting holes. The peripheries of the upper glass and each air extracting hole are provided with sealing strips. Corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips. After being heated, the upper glass and the lower glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace. A sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

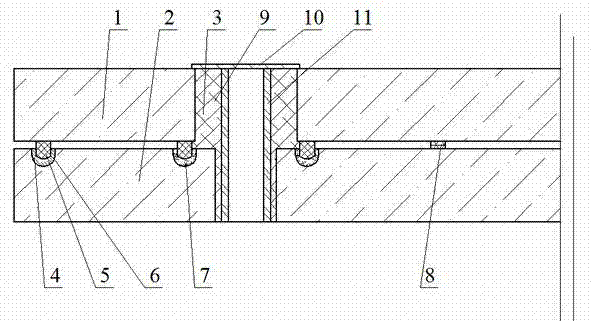

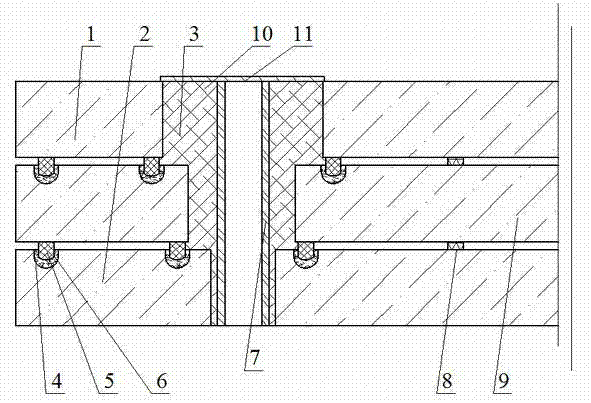

Metal-welded plain vacuum glass provided with edges sealed by sealing grooves and sealing strips and manufacturing method thereof

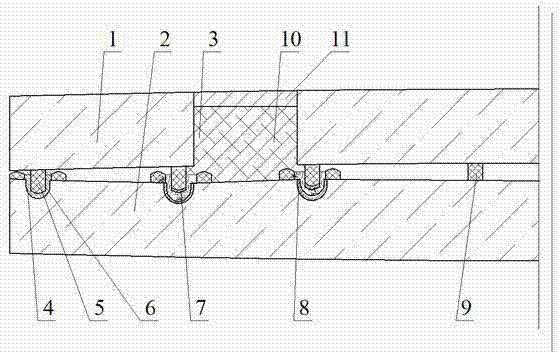

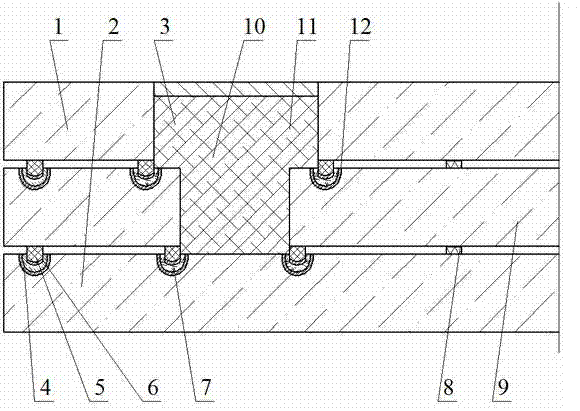

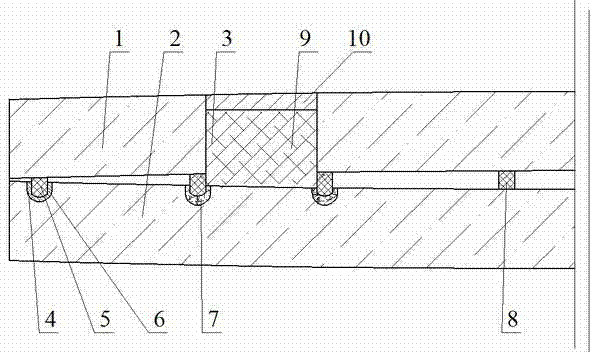

Metal-welded plain vacuum glass provided with edges sealed by sealing grooves and sealing strips is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the periphery of the upper glass is provided with sealing strips; corresponding positions of the periphery of the lower glass are provided with the sealing grooves and sealing strips; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by metal solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded sealed convex vacuum glass with edges and extraction openings sealed by sealing strips and production method thereof

InactiveCN104743850AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingConvex side

The invention relates to a glass-welded sealed convex vacuum glass with edges and extraction openings sealed by sealing strips, which comprises an upper glass and a lower glass, 1-4 extraction openings are arranged on the upper glass, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are respectively provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, and the extraction opening is performed with on-line enclosing by using molten glass in a continuous vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

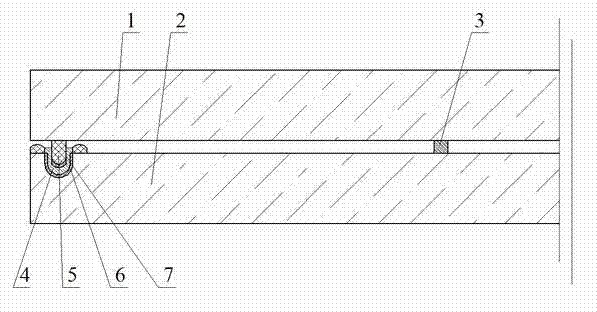

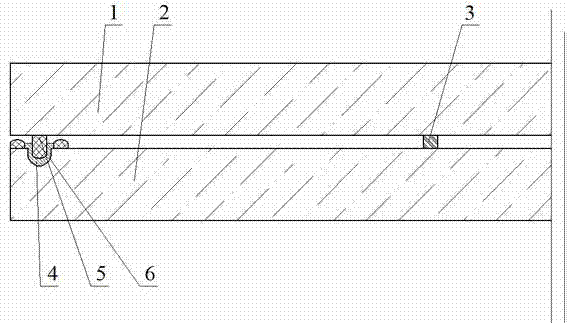

Glass-welded plain vacuum glass with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743832AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

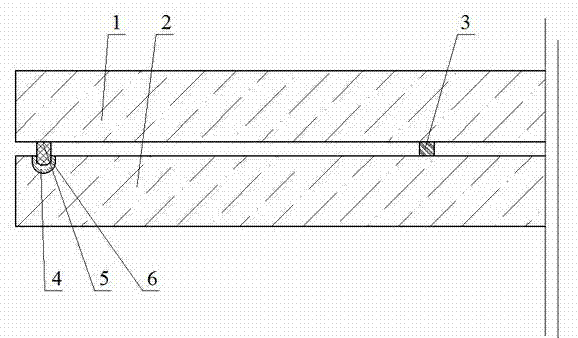

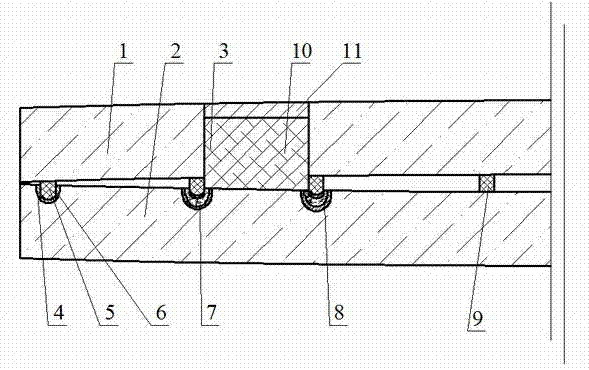

Glass-welded plain vacuum glass with edges sealed by sealing grooves is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the upper glass is provided with sealing strips; the periphery of the lower glass is provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

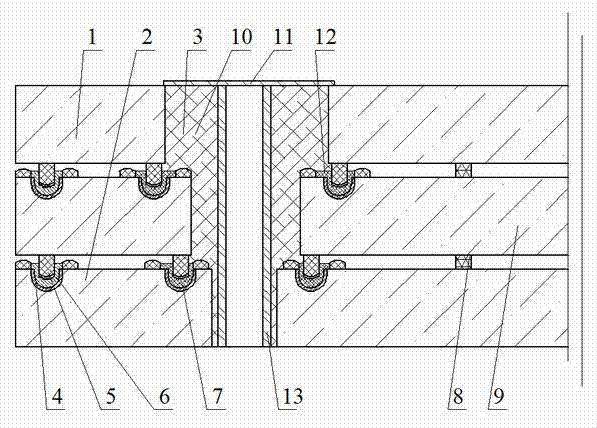

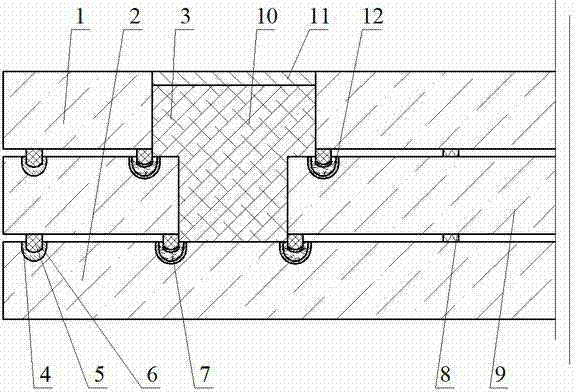

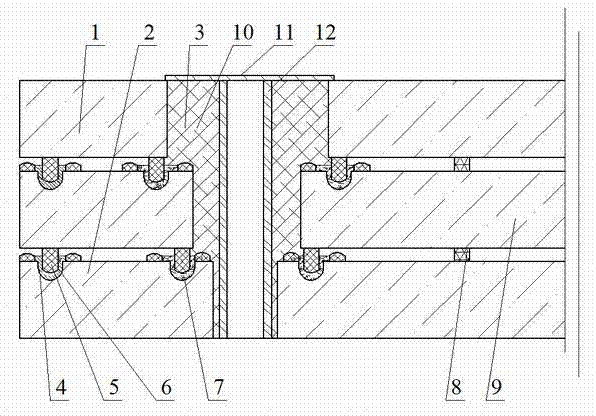

Metal-welded plain double-vacuum-layer glass provided with edges sealed by sealing strips and sealing grooves and provided with mounting hole(s)

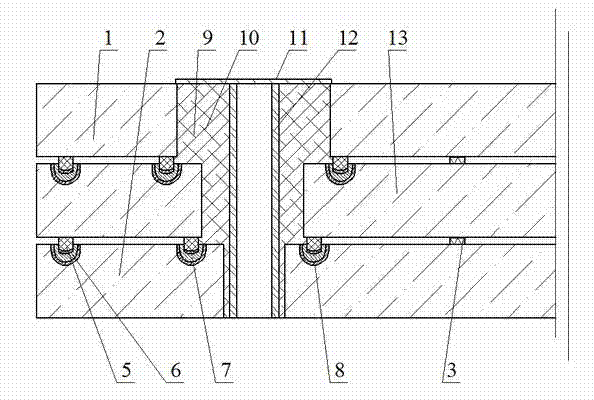

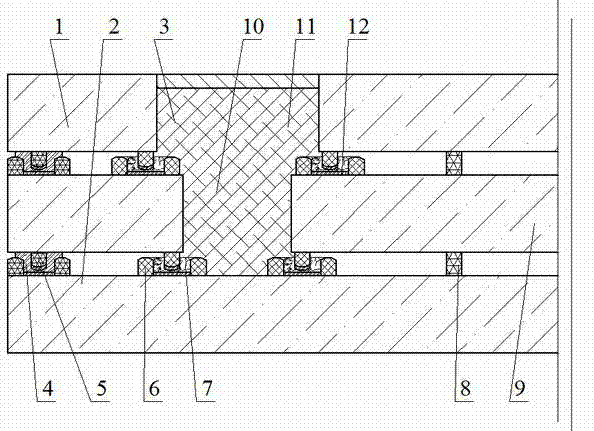

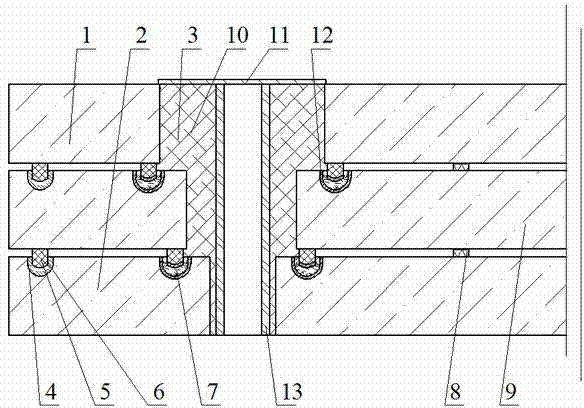

Metal-welded plain double-vacuum-layer glass provided with edges sealed by sealing strips and sealing grooves and provided with mounting hole(s) is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the lower surface of the upper glass, the lower surface of the middle glass and the periphery of each air extracting hole are provided with sealing strips; corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace; each air extracting hole is sealed by utilization of metal solder in a vacuum furnace; two sealed vacuum layers are formed among the three sheets of glass; and supports arranged in a point array are disposed in the vacuum layers. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded plain vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743818AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded plain vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The plain vacuum glass comprises upper glass and lower glass. The plain vacuum glass is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the peripheries of the upper glass and each air extracting hole are provided with sealing strips; corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the middle glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is sealed on line by utilization of melted glass in a continuous vacuum furnace; one sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

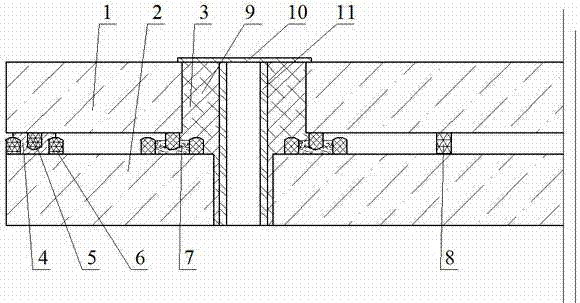

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

InactiveCN104743792AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: the plain double-vacuum-layer glass is provided with the mounting hole(s); the number of the mounting hole(s) is 1-4; the lower surfaces of the upper glass and the middle glass and the periphery of each mounting hole are provided with sealing strips; corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and the mounting hole(s) are provided with the sealing grooves and sealing strips; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass and the periphery of each mounting hole are welded under elevated pressure by glass solder in a vacuum furnace; and two sealed vacuum layers are formed among the three sheets of glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Metal-welded plain vacuum glass with installing holes and edge sealed by sealing strips

The invention relates to a metal-welded plain vacuum glass with installing holes and edge sealed by sealing strips, which comprises an upper glass and a lower glass, the installing holes and extraction openings are combined as an integral body, 1-4 installing holes are arranged, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through an alloy solder in an atmosphere heating furnace, and the extraction opening is enclosed by using metal solder in vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing grooves and manufacturing method thereof

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing grooves is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass. The upper glass and the middle glass are provided with one to four air extracting holes. The lower surface of the upper glass, the lower surface of the middle glass and the periphery of each air extracting hole are provided with sealing strips. Corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves. After being heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass, the middle glass and the lower glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace. Each air extracting hole is sealed by utilization of metal solder in a vacuum furnace. Two sealed vacuum layers are formed among the upper glass, the middle glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded plane glass low-altitude glass with edge sealed by sealing grooves and production method thereof

InactiveCN104743865AShorten the timeMaintain tempered propertiesGlass reforming apparatusGlass productionHigh volume manufacturingHeating furnace

The invention relates to a glass-welded plane glass low-altitude glass with edge sealed by sealing grooves, which comprises an upper glass and a lower glass, a sealing strip is provided at the upper glass, a seal groove is arranged at circumference of the lower glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, an enclosing low-altitude layer is formed between the upper glass and the lower glass, and the supporters with lattice arrangement are arranged in the low-altitude layer. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

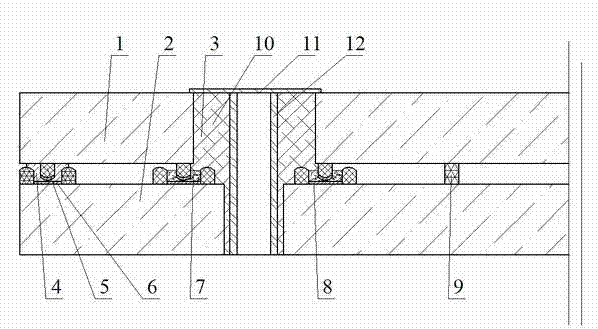

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing strips and manufacturing method thereof

Metal-welded sealed plain double-vacuum-layer glass with edges sealed by sealing strips is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass which are plain glass. The upper glass and the middle glass are provided with one to four air extracting holes. The periphery of the lower surface of the upper glass, the periphery of the lower surface of the middle glass and the periphery of each air extracting hole are respectively provided with at least one sealing strip. The peripheries of the upper surfaces of the middle glass and the lower glass are provided with at least two sealing strips. A position on the lower glass, which is corresponding to each air extracting hole, is provided with at least one sealing strip. Peripheries of the three sheets of glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace. Each air extracting hole is sealed by utilization of metal solder in a vacuum furnace. A manufacturing method of the plain double-vacuum-layer glass is simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded plane double-low altitude-layer glass with edge sealed by sealing grooves and strips and production method thereof

InactiveCN104743855AShorten the timeMaintain tempered propertiesGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

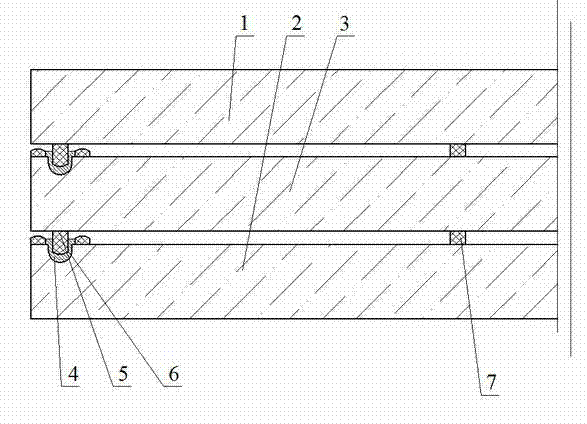

The invention relates to a glass-welded plane double-low altitude-layer glass with edge sealed by sealing grooves and strips, which comprises an upper glass, a lower glass and an intermediate glass, the sealing strips are provided at lower surfaces of the upper glass and the intermediate glass, the seal groove and the sealing strips are arranged on the upper surface circumference of the intermediate glass and the lower glass, three glasses are rapidly heated, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, and two enclosing low-altitude layers are formed between the upper glass and the intermediate glass as well as between the intermediate glass and the lower glass. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

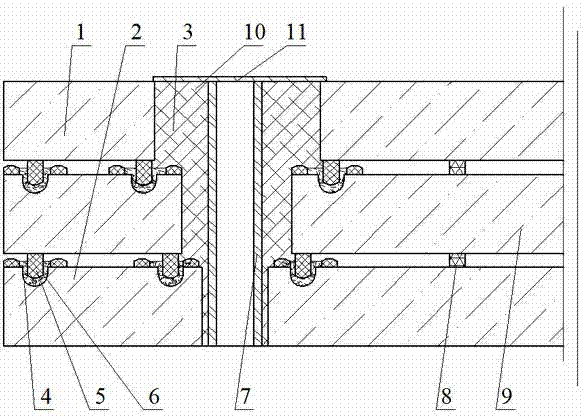

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743833AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

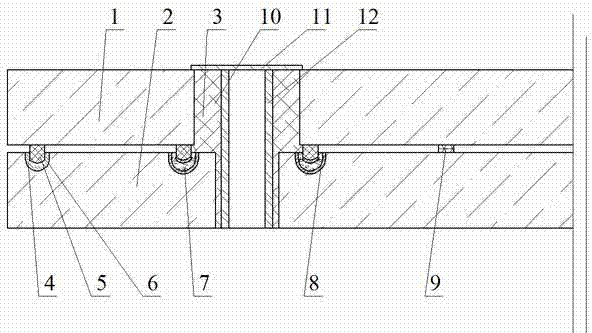

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: the lower surfaces of the upper glass and the middle glass are provided with sealing strips; the peripheries of the upper surfaces of the middle glass and the lower glass are provided with the sealing grooves; after being rapidly heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass, the middle glass and the lower glass are welded under elevated pressure by glass solder in a vacuum furnace; and two sealed vacuum layers are formed among the upper glass, the middle glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

High-temperature-sheet-combination sealed plain double-vacuum-layer glass with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743809AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination sealed plain double-vacuum-layer glass with edges sealed by sealing grooves is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass. The upper glass and the middle glass are provided with one to four air extracting holes. The lower surface of the upper glass, the lower surface of the middle glass and the periphery of each air extracting hole are provided with sealing strips. Corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves. After being heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass, the middle glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace. Two sealed vacuum layers are formed among the upper glass, the middle glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Plain vacuum glass with installing holes by glass welding at sealed edge of sealing strip

InactiveCN104743843AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

The invention relates to a plain vacuum glass with installing holes at sealed edge of a sealing strip, which comprises an upper glass and a lower glass, the installing holes and extraction openings are combined as an integral body, 1-4 installing holes are arranged, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, and the extraction opening is performed with on-line enclosing by using molten glass in a continuous vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

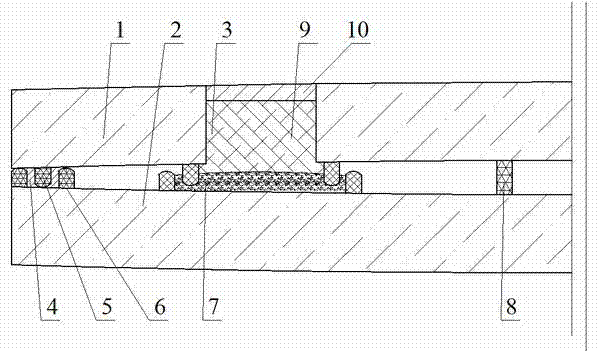

Glass-welded plain vacuum glass with edges sealed by sealing grooves and sealing strips and manufacturing method thereof

InactiveCN104743834AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

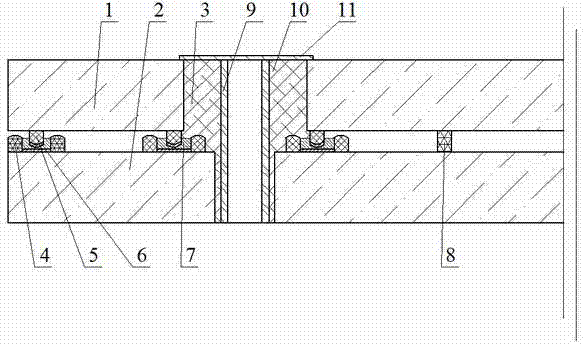

Glass-welded plain vacuum glass with edges sealed by sealing grooves and sealing strips is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the upper glass is provided with sealing strips; the periphery of the lower glass is provided with the sealing grooves and sealing strips; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded sealed convex vacuum glass with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743828AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingConvex side

Glass-welded sealed convex vacuum glass with edges sealed by sealing grooves is disclosed. The convex vacuum glass comprises upper glass and lower glass which are convex glass. The upper glass is provided with one to four air extracting hole. The peripheries of the upper glass and each air extracting hole are provided with sealing strips. Corresponding positions of the peripheries of the lower glass and each air extracting hole are provided with the sealing grooves. After being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is sealed on line by utilization of melted glass in a continuous vacuum furnace. A sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

High-temperature-sheet-combination plain vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743808AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination plain vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; peripheries of the upper glass and each air extracting hole are provided with sealing strips; corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Metal-welded plane vacuum glass having installing holes and edge sealed by sealing strips

The invention relates to a metal-welded plane vacuum glass having installing holes and edge sealed by sealing strips, which comprises an upper glass and a lower glass, the installing holes are provided, 1-4 installing holes are provided, at least a sealing strip is provided at circumference of the upper glass and the installing hole, at least two sealing strips are provided at circumference of the lower glass and the installing hole, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, and the circumference can be welded together by pressurizing through a metal solder in a vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, and usage life is increased.

Owner:戴长虹

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing grooves and manufacturing method thereof

InactiveCN104743788AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingConvex side

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing grooves is disclosed. The convex vacuum glass comprises upper glass and lower glass which are convex glass. The upper glass is provided with one to four air extracting holes. The peripheries of the upper glass and each air extracting hole are provided with sealing strips. Corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves. After being heated, the upper glass and the lower glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace. A sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing strips and manufacturing method thereof

InactiveCN104743782AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination sealed convex vacuum glass with edges sealed by sealing strips is disclosed. The convex vacuum glass comprises upper glass and lower glass which are convex glass. The upper glass is provided with one to four air extracting holes. The peripheries of the upper glass and each air extracting hole are respectively provided with at least one sealing strip. The periphery of the lower glass is provided with at least two sealing strips. A position on the lower glass, which is corresponding to each air extracting hole, is provided with at least one sealing strip. The sealing strip of the upper glass is inserted between or into the sealing strips of the lower glass. After being rapidly heated, the upper glass and the lower glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

High-temperature-sheet-combination plain double-vacuum-layer glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743794AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination plain double-vacuum-layer glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the lower surfaces of the upper glass and the middle glass and the periphery of each air extracting hole are provided with sealing strips; corresponding positions of peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves; after being rapidly heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass, the middle glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace; and each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

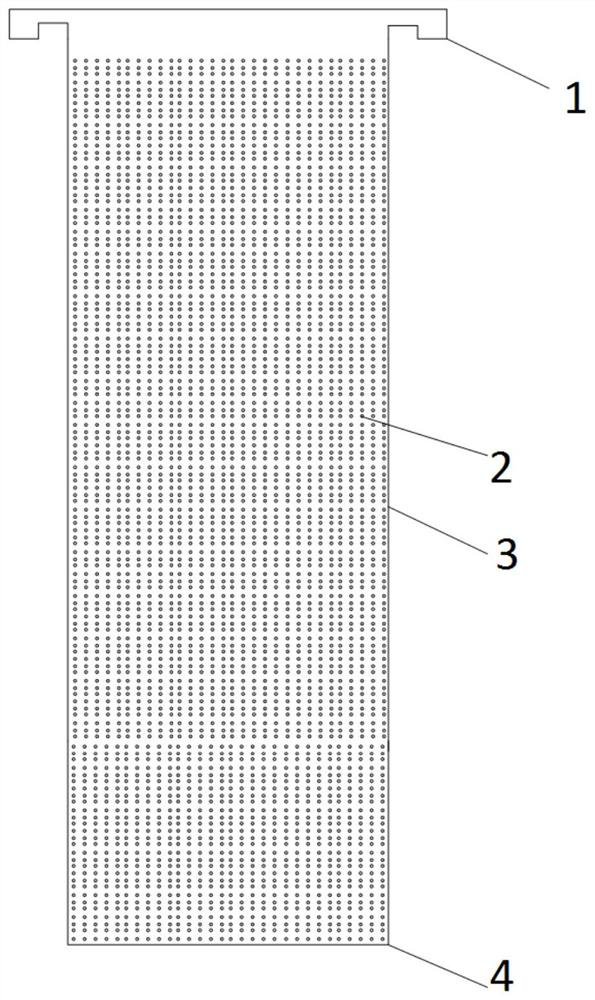

Fused deposition modeling 3D printing mercury removal bag cage and preparation method thereof

ActiveCN112519283ALarge specific surface areaIncrease loadGas treatmentAdditive manufacturing apparatus3d printCarbide silicon

The invention discloses a fused deposition modeling 3D printing mercury removal bag cage and a preparation method thereof. The preparation method includes the steps that mercury removal catalytic powder is prepared firstly, and then the mercury removal catalytic powder, polytetrafluoroethylene powder, polyimide powder, nano silicon dioxide, paraffin and silicon carbide powder are mixed to preparefilamentous materials to be used as 3D printing raw materials; the mercury removal bag cage is prepared from the 3D printing raw materials through a fused deposition modeling technology. Compared withthe combination of a conventional bag cage and a mercury removal filter bag, the mercury removal bag cage has the advantages that a catalyst is implanted into the mercury removal bag cage through rawmaterial blending in the preparation process of the bag cage, so that the catalyst is uniformly distributed in the bag cage, the catalytic stability of the whole bag cage is good, and the mercury removal efficiency is high.

Owner:XIAN THERMAL POWER RES INST CO LTD

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

InactiveCN104743835AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingFused glass

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the lower surfaces of the upper glass and the middle glass and the periphery of each air extracting hole are provided with sealing strips; corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is sealed on line by utilization of melted glass in a continuous vacuum furnace; and two sealed vacuum layers are formed among the three sheets of glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743785AIncrease productivityIncrease heating rateGlass reforming apparatusGlass productionVacuum furnaceEngineering

Glass-welded plain double-vacuum-layer glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The plain double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: the plain double-vacuum-layer glass is provided with the mounting hole(s); the lower surfaces of the upper glass and the middle glass and the periphery of each mounting hole are provided with sealing strips; corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass and each mounting hole are provided with the sealing grooves; after being rapidly heated, the upper glass and the middle glass as well as the lower glass and the middle glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass, the middle glass and the lower glass and the periphery of each mounting hole are welded under elevated pressure by glass solder in a vacuum furnace; and two sealed vacuum layers are formed among the upper glass, the lower glass and the middle glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass-welded plain vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743820AIncrease productivityIncrease heating rateGlass reforming apparatusGlass productionVacuum furnaceEngineering

Glass-welded plain vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the plain vacuum glass is provided with the mounting hole(s), the number of the mounting hole(s) is 1-4; the peripheries of the upper glass and each mounting hole are provided with sealing strips; corresponding positions of the periphery of the lower glass and each mounting hole are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the middle glass and the periphery of each mounting hole are welded under elevated pressure by glass solder in a vacuum furnace; one sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

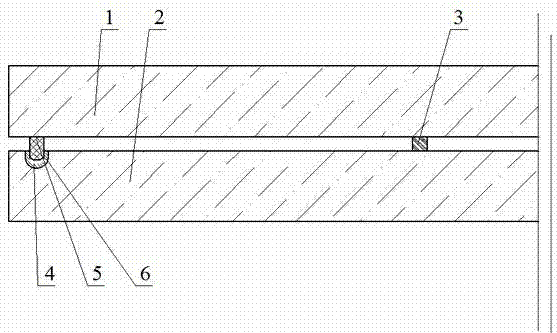

Glass-welded sealed plain vacuum glass with edges sealed by sealing strips and manufacturing method thereof

InactiveCN104743800AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

Glass-welded sealed plain vacuum glass with edges sealed by sealing strips is disclosed. The plain vacuum glass comprises upper glass and lower glass which are plain glass. The upper glass is provided with air extracting hole(s). The peripheries of the upper glass and each air extracting hole are respectively provided with at least one sealing strip. The peripheries of the lower glass and each air extracting hole are respectively provided with at least two sealing strips. The sealing strip of the upper glass is inserted between the sealing strips of the lower glass. After being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the middle glass are welded under elevated pressure by glass solder in a heating furnace. Each air extracting hole is sealed on line by utilization of melted glass in a continuous vacuum furnace. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Selective thermal sintering molding 3D printing mercury removal bag cage and preparation method thereof

ActiveCN112590204AIncrease loadEvenly distributedAdditive manufacturing apparatusGas treatment3d printImide

The invention discloses a selective thermal sintering molding 3D printing mercury removal bag cage and a preparation method thereof. The preparation method includes the steps that mercury removal catalytic powder, polytetrafluoroethylene powder, nano silicon dioxide, polyimide powder, didodecanol ester, and dioctyl phthalate serve as raw materials, a 3D printing material is obtained after ball milling, melting, stirring and extrusion granulation are conducted, and the mercury removal bag cage is prepared through a selective thermal sintering 3D printing technology. According to the selective thermal sintering molding 3D printing mercury removal bag cage and a preparation method thereof, the mercury removal bag cage is prepared by jumping out of a filter bag mercury removal frame, changingideas, organically combining functions and a main body on one main body and loading a catalyst on a filter bag cage by adopting the 3D printing technology, so that the catalyst loading capacity is large, and the catalyst is uniformly distributed in the bag cage; micropores are fully distributed in the bag cage, so that the contact area between the bag cage and flue gas is increased; and compared with a conventional bag cage, the filter bag is more fully and uniformly supported, the stress on the surface of the filter bag is further reduced, the service life of the filter bag is prolonged, industrial large-scale production is facilitated, and the engineering application value is high.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com