High-precision electronically controlled aperture device

A high-precision, aperture technology, applied in optics, optical components, instruments, etc., can solve the problems that the circular shrinking aperture cannot be completely closed, and the linear adjustment of the Gaussian beam intensity cannot be achieved, achieving compact structure and reduced size , to ensure the effect of linear motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

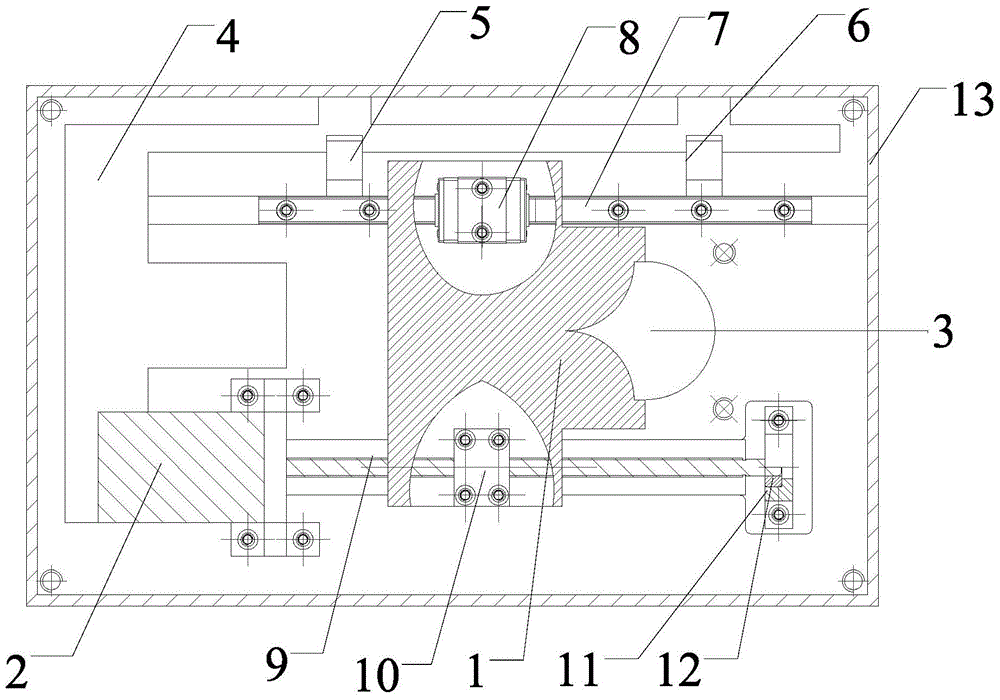

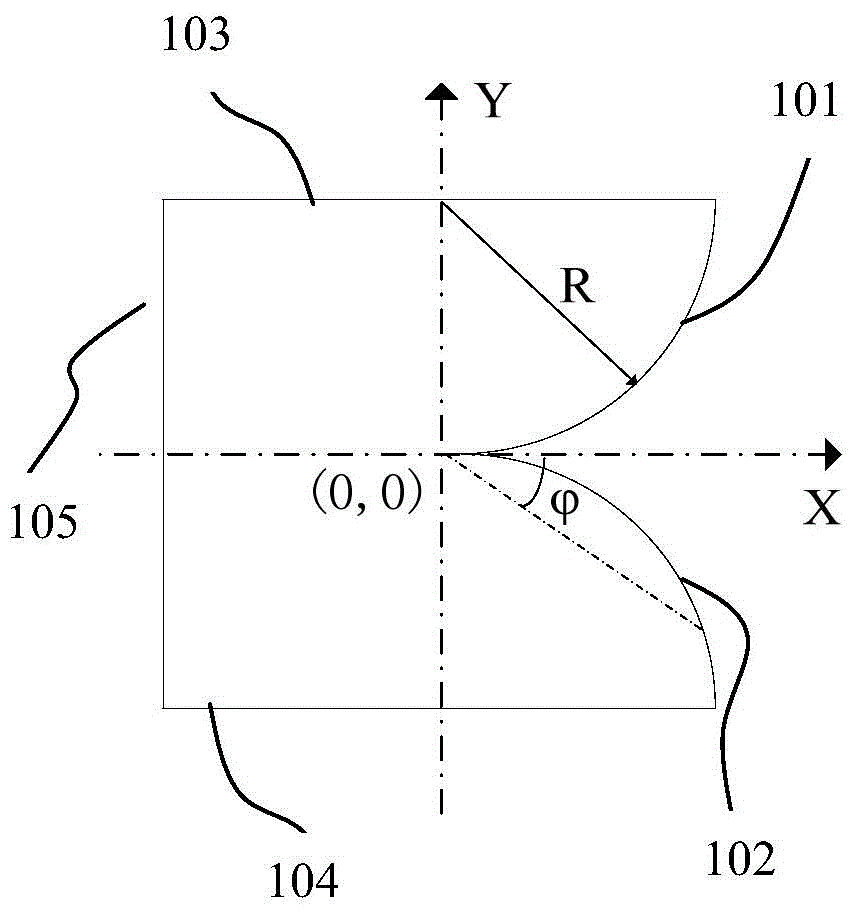

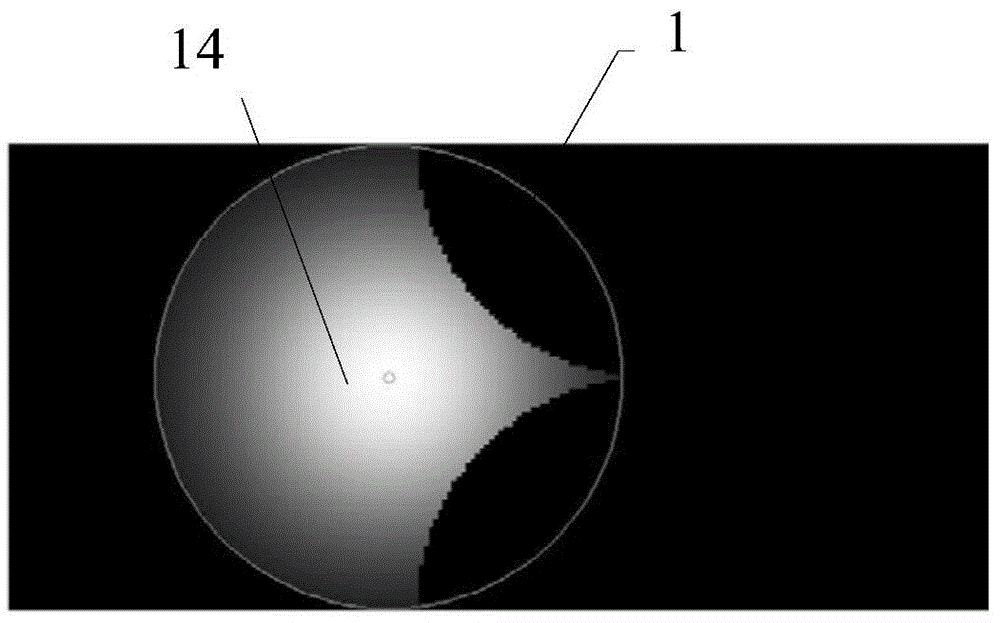

[0031] see figure 1 , the present invention provides a high-precision electronically controlled diaphragm device, which includes a double-arc diaphragm 1, a driving mechanism 2, a transmission mechanism, a limit switch, a controller, and a base with a circular light opening 3 at the bottom 4. The driving mechanism 2 is arranged on the base 4 and connected to the controller; the transmission mechanism includes a pair of guide rail sliders arranged on the base 4 and wires arranged on both sides of the circular light opening 3 in parallel with the pair of guide rail sliders. rod; the lead screw is set along the power output direction of the drive mechanism 2, one end of the lead screw is connected with the drive mechanism 2, and the other end is fixed on the side of the base 4; the double arc diaphragm 1 is set on the guide rail slider pair and the lead screw ; The double-arc aperture 1 is a sheet structure, and its contour line includes a first arc edge 101 and a second arc edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com