Low temperature dyeing process of nylon/polyester elastic knitted fabric

A low-temperature dyeing technology for knitted fabrics, applied in dyeing, textiles, and papermaking, can solve the problems of scrapped fabrics, poor color fastness of fabrics, and high dyeing costs, so as to reduce the risk of scrapping, improve color fastness, and reduce dyeing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Fabric: 70D / 48F Nylon 6+70D / 36F low temperature cationic modified polyester DTY+40D OP spandex jersey

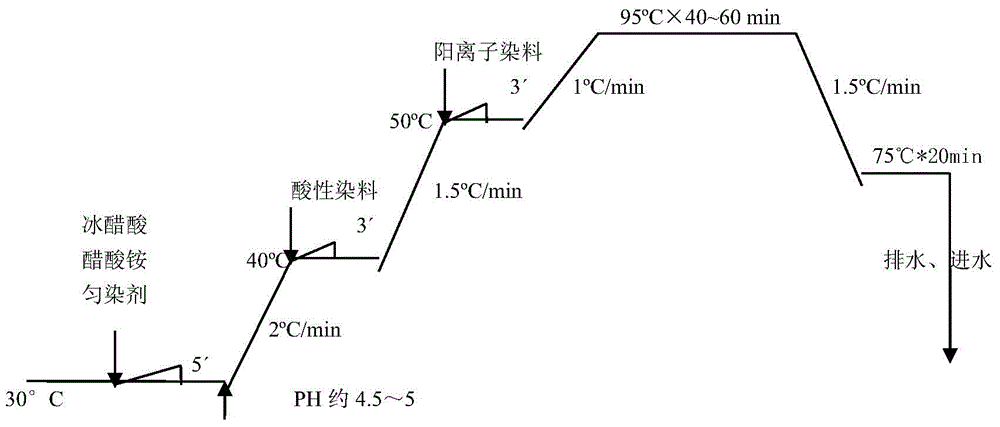

[0026] 2. The process flow is as follows:

[0027] Weaving→Cylinder matching→Shrinking→Dehydration→Open width→Pre-setting→Dyeing→Dehydration→Expanding→Finished product shaping→Inspection→Packaging

[0028] 3. The low-temperature dyeing process of nylon / polyester elastic knitted fabric of the present invention, the key points of the process are as follows:

[0029] (1) For the polyester yarn in the raw material, low-temperature cationic modified polyester DTY (that is, low-temperature cationic DTY) is used to replace the original ordinary polyester DTY;

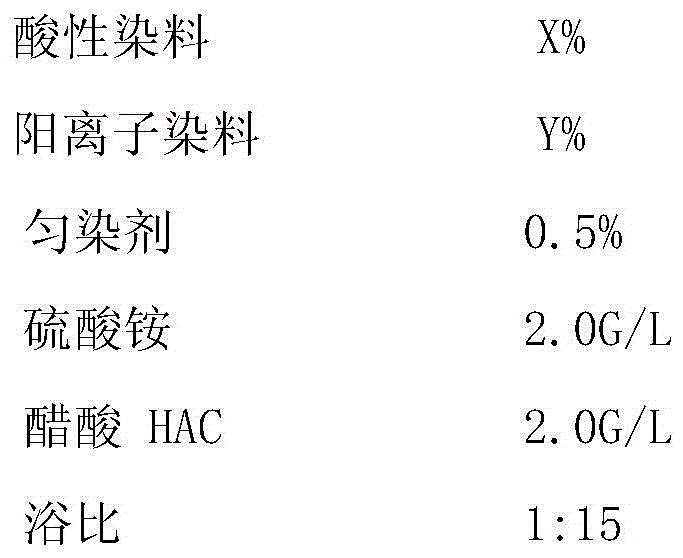

[0030] (2) Low-temperature dyeing one-bath processing formula (color 17-2127TCX):

[0031]

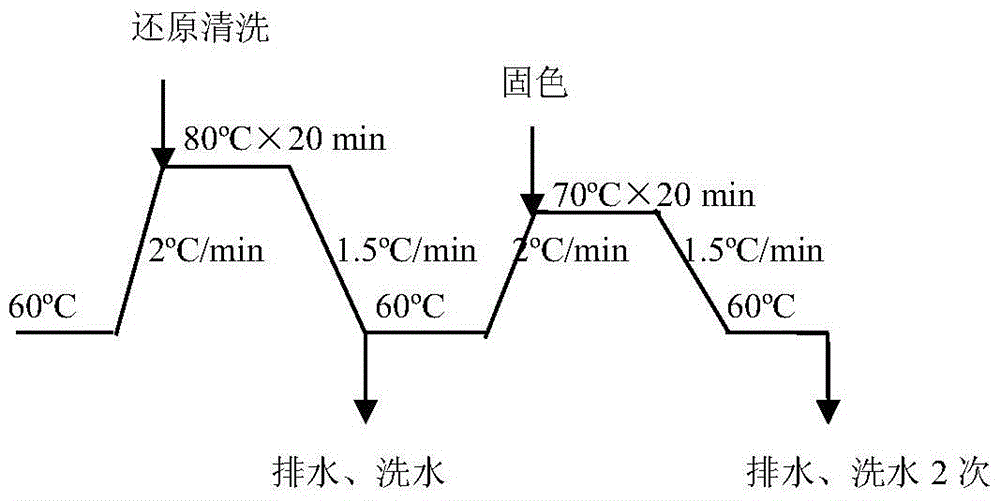

[0032] (Wherein, the X and Y values are determined according to the different colors to be finally dyed) (2) Post-treatment process formula:

[0033] Polyester reduction cleaning

[0034] Acid reduction cleaning ag...

Embodiment 2

[0050] 1. Fabric: 100D / 48F Nylon 6+50D / 36F low-temperature cationic modified polyester DTY+40D OP reverse-wrapped single-sided fleece

[0051] 2. The process flow is as follows:

[0052] Weaving→Cylinder matching→Shrinking→Dehydration→Open width→Pre-setting→Dyeing→Dehydration→Expanding→Styling and drying→Styling plus fluffing agent→Napping→Centering→Carding→Shearing→Finished product shaping→Inspection→Packaging

[0053] 3. The low-temperature dyeing process of nylon / polyester elastic knitted fabric of the present invention, the key points of the process are as follows:

[0054] (1) The polyester yarn in the raw material adopts low-temperature cationic modified polyester DTY (this low-temperature cationic modified polyester DTY is purchased from Shenghong Group Co., Ltd.) to replace the original common polyester DTY;

[0055] (2) Low-temperature dyeing one-bath processing formula (color 17-2127 TCX):

[0056]

[0057] (3) Post-treatment process formula:

[0058] Polyester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com