Chord stepping device in steel truss production line

A steel truss and production line technology, which is applied to wire netting, wire processing, and other household appliances, can solve the problems of different lengths of steel truss products, affecting the stepping accuracy of the truss, and affecting the stepping speed, etc., to achieve simple structure and step-by-step The effect of high precision and elimination of time wastage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

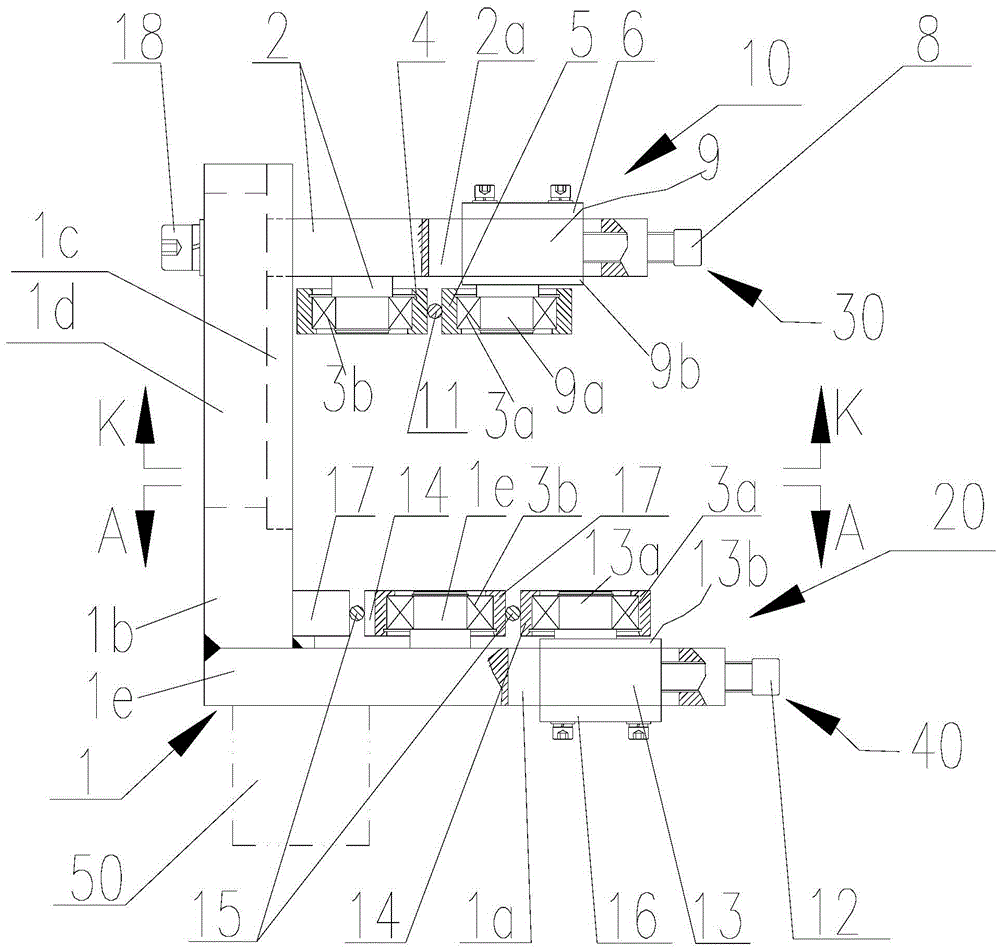

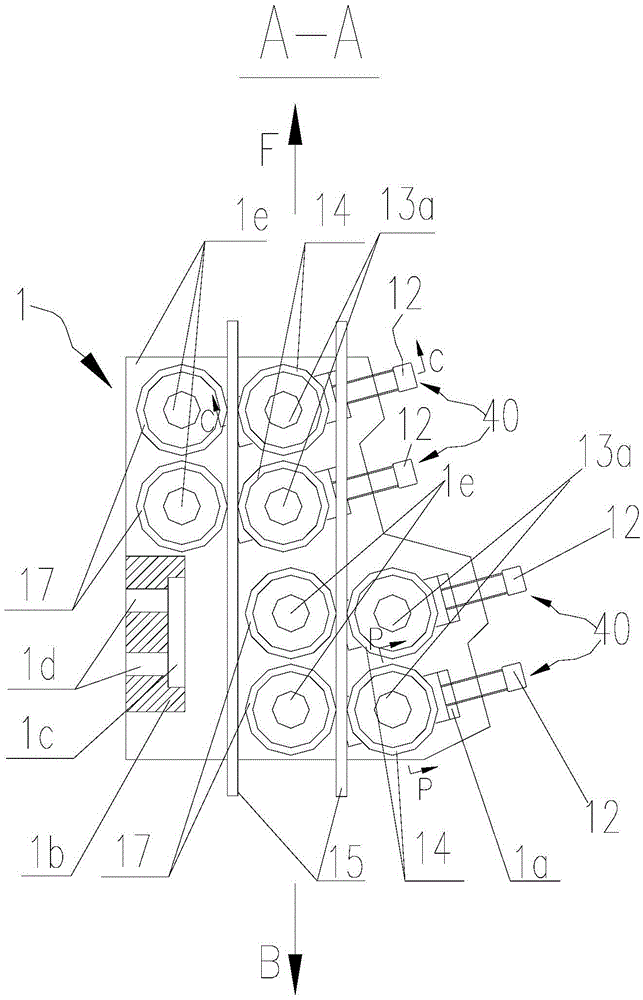

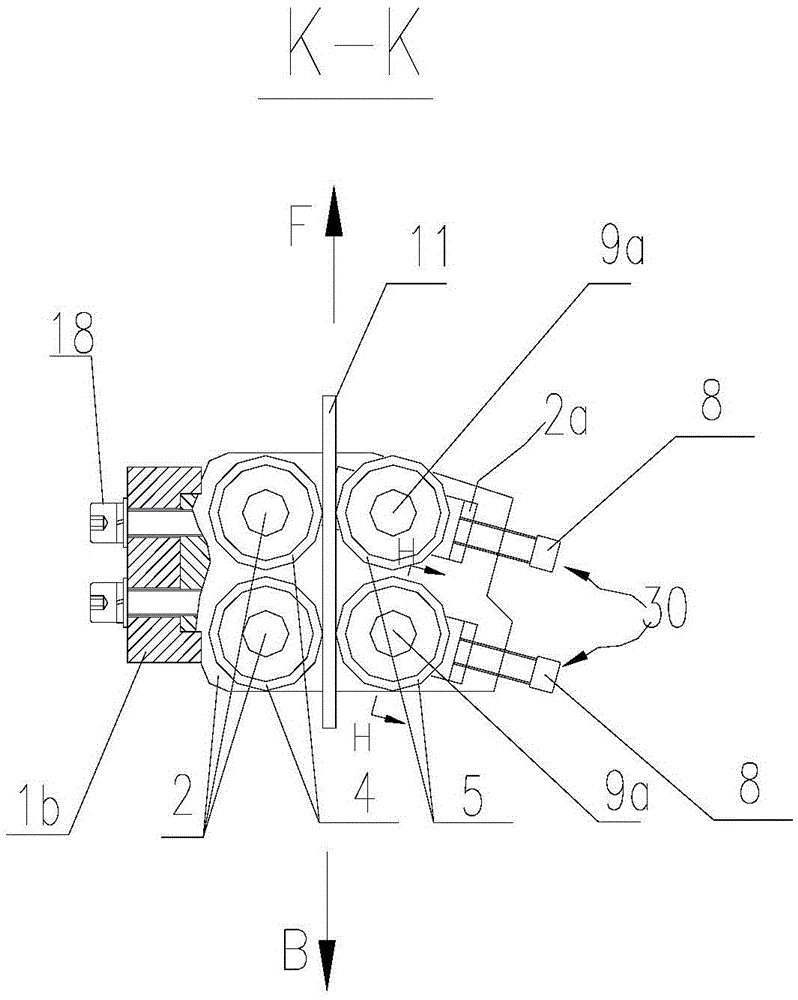

[0027] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0028] As shown in the figure, the present invention provides a chord stepping device in a steel bar truss production line. The chord stepping device includes: a stepping frame 1 connected to a reciprocating movement mechanism 50, and the stepping frame 1 is composed of a horizontal frame 1e and The vertical frame 1b is composed of; the horizontal frame 1e is located at the bottom of the stepping frame 1, and the lower pressing part 20 for clamping the lower chord bar 15 is arranged on the horizontal frame 1e; the vertical frame 1b is fixed on the horizontal frame 1e, The upper pressing part 10 for clamping the upper chord bar 11 is arranged on the vertical frame 1b.

[0029] The lower pressing part 20 includes: the lower fixed wheel 17 and the lower movable wheel 14 clamped on both sides of the lower string bar 15; the inner hole of the lower fixed wheel 17 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com