Method for predicting storage life of NEPE (nitrate ester plasticized polyether) propellant based on deadweight induced pressure condition

A storage life and propellant technology, which is applied in the field of NEPE propellants, can solve problems such as the decline in the mechanical properties of charges, the impact on the safe use and storage life of large-size NEPE propellants, and the impact of NEPE propellant storage life without consideration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0053] 1. Carry out accelerated tests at different temperatures under constant stress loads

[0054] ①Simulate 300kg charge to make NEPE propellant accelerated aging test pieces

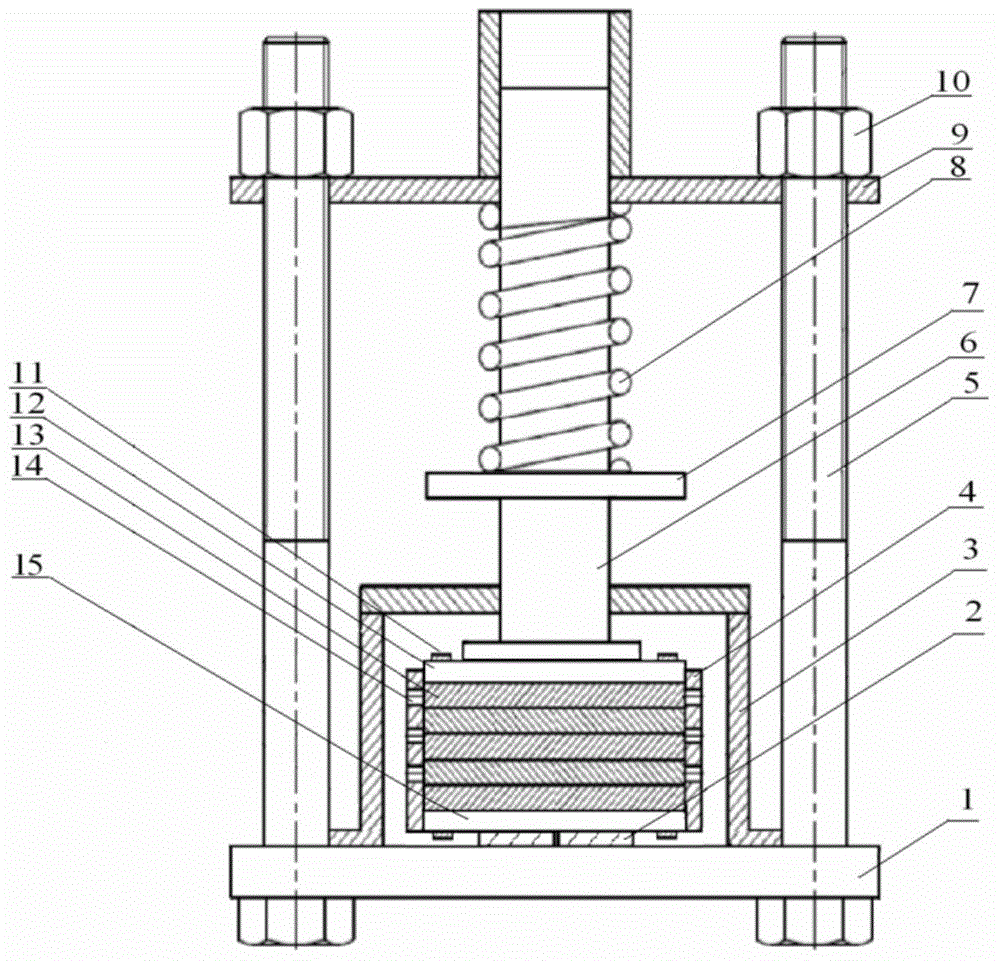

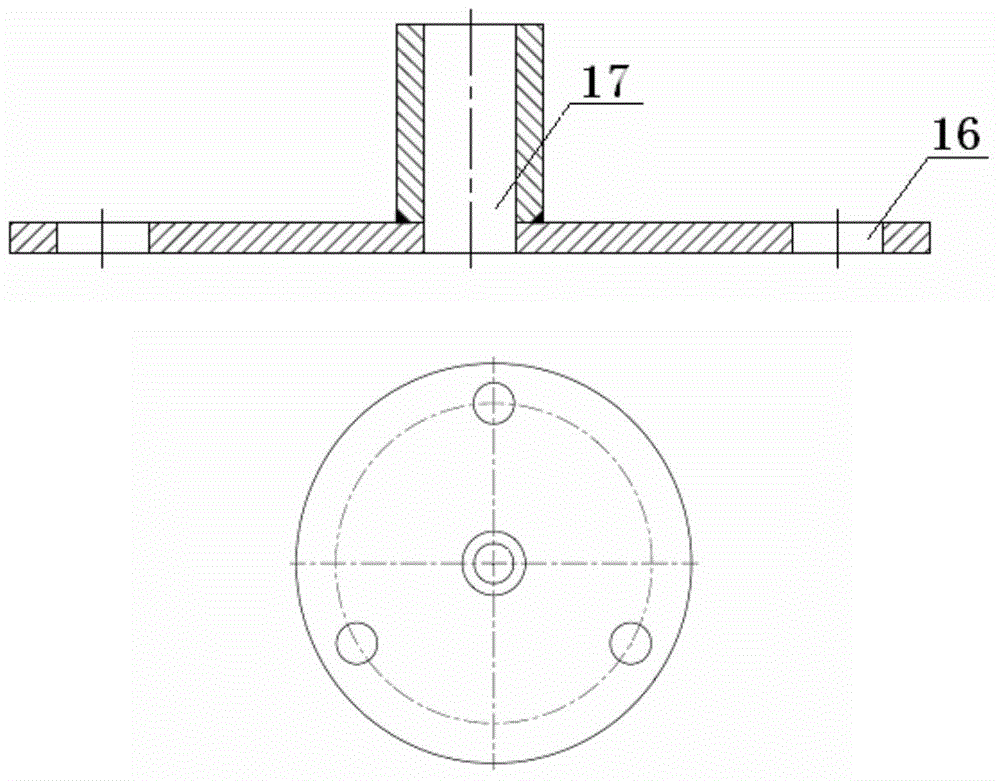

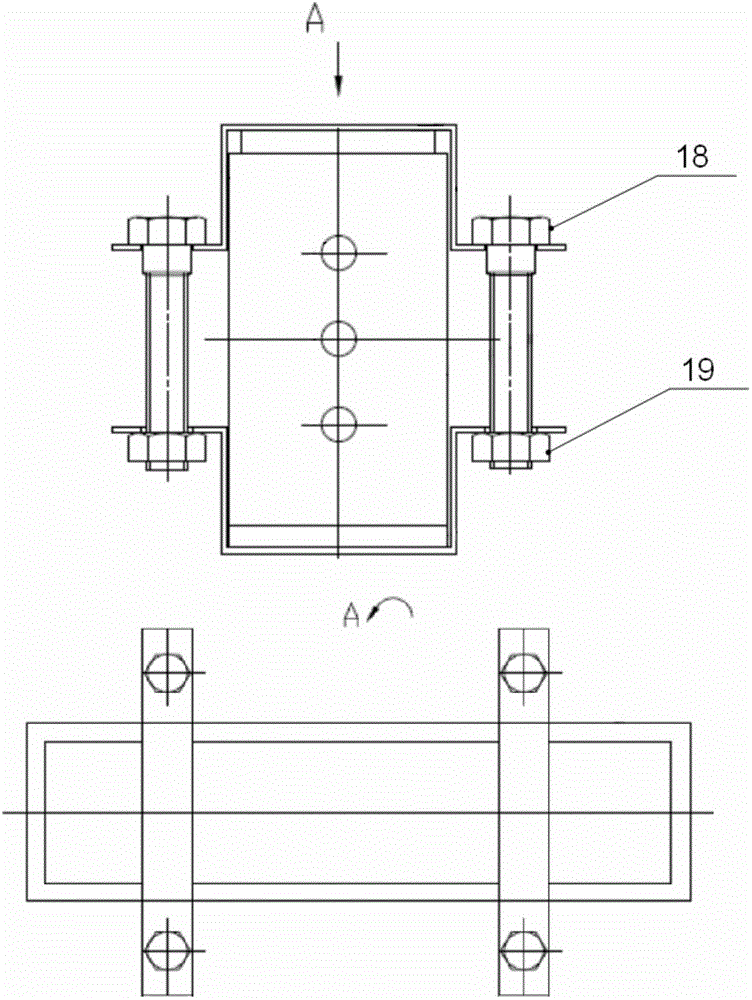

[0055] The schematic diagram of the pressure loading device is shown in figure 1 , see the schematic diagram of the cover figure 2 , the assembly diagram of the sample box is shown in image 3 , the schematic diagram of the assembly section of the sample box is shown in Figure 4 , the schematic diagram of the bottom plate of the sample box is shown in Figure 5 , the schematic diagram of the cover plate of the sample box is shown in Image 6 , see the schematic diagram of fastening card Figure 7 .

[0056] The pressure loading device consists of three parts: a support unit, a pressure loading unit, and a sample box device.

[0057] The supporting unit is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com