Defect grade judgment method for liquid crystal modules of different production lines

A defect level, liquid crystal module technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of inconvenient management, inconvenient maintenance, and many application environments, so as to reduce the number of versions, reduce the amount of code, and expand strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

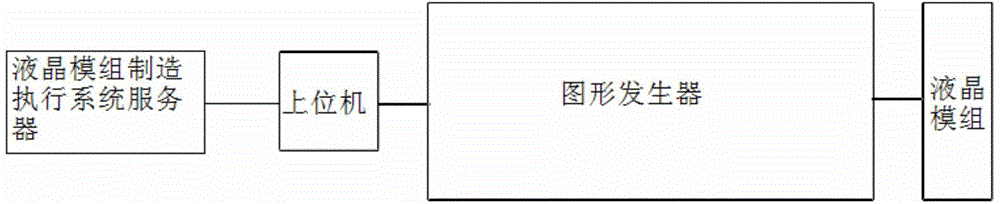

[0024] The devices on which the present invention is based such as figure 1 As shown, it includes the liquid crystal module manufacturing execution system server, host computer, graphic generator and liquid crystal module connected in sequence. This solution can manually edit and modify the code initialization file, move the work done in the previous host computer program to the external initialization file, and quickly modify and correct the code, which is flexible and convenient.

[0025] The scheme of the present invention is that the upper computer connects the graphics generator and the liquid crystal module manufacturing execution system server (MES, manufacturing execution system) through the network, and the user edits the defect level initialization file according to a specific format through an external text editing tool to realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com