Sealing structure of DC contactor

A DC contactor, sealing structure technology, applied in relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problem that the working temperature can only be -40 ℃ ~ +85 ℃, the environmental adaptability is poor, the sealing effect is not good, etc. problems, to achieve the effect of strong environmental adaptability, improved production efficiency, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following examples, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

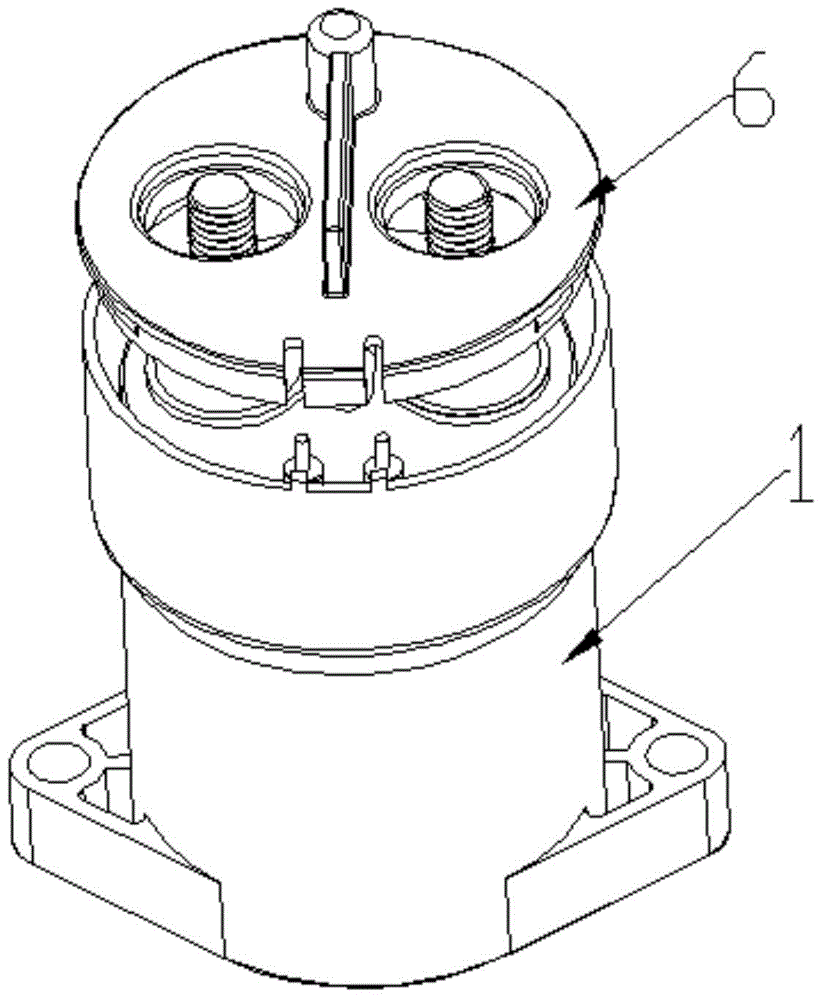

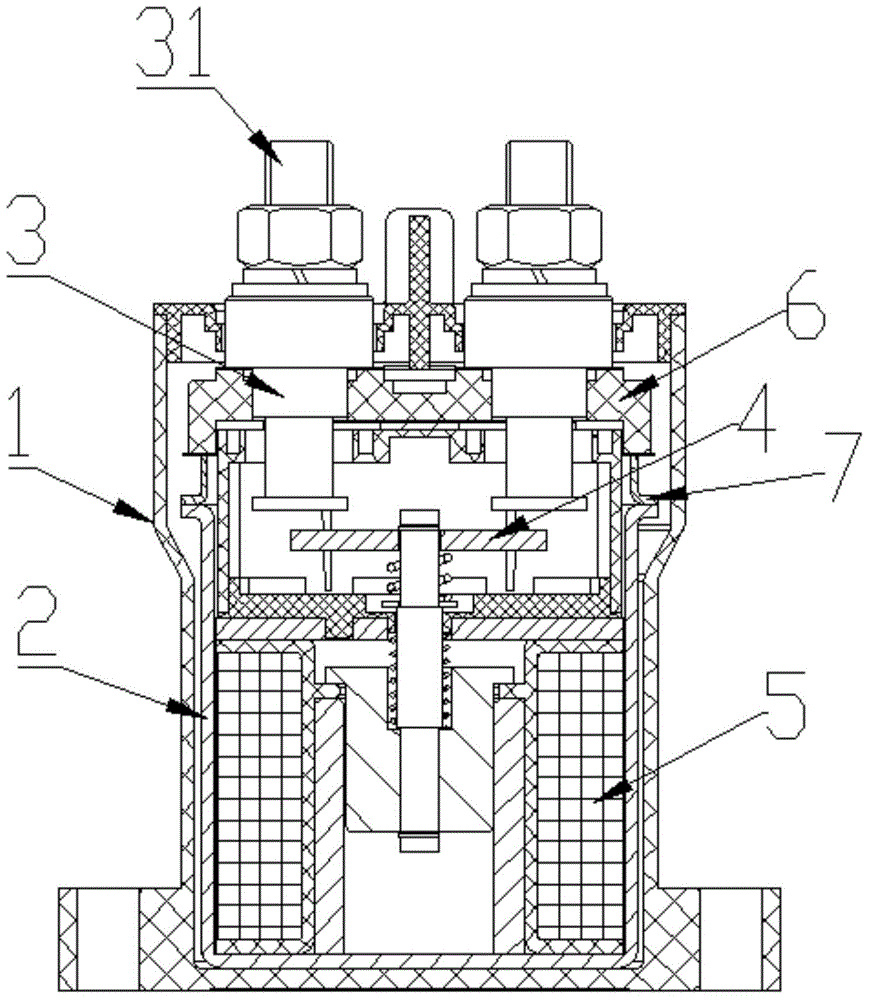

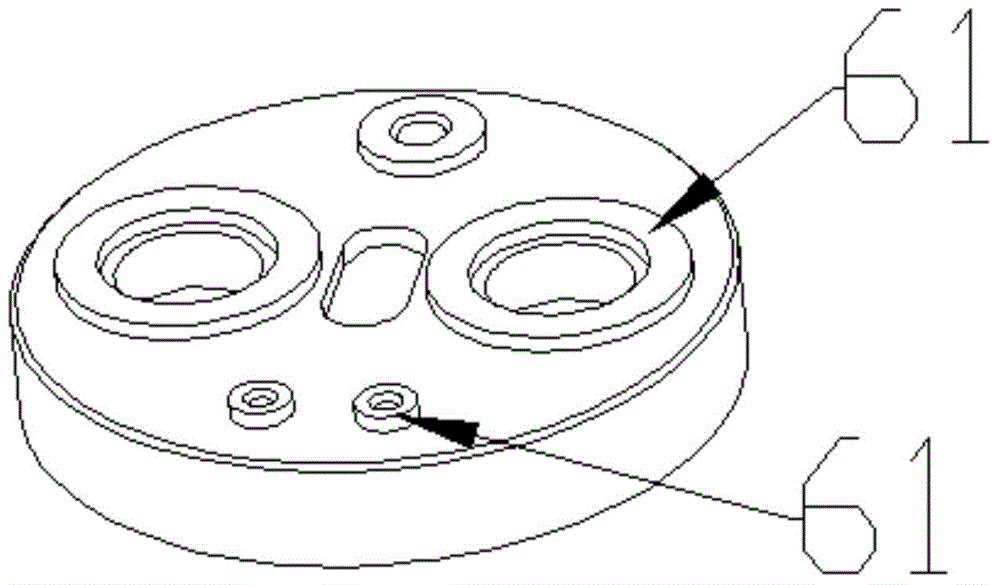

[0023] Such as Figure 1-5 As shown, a DC contactor sealing structure includes a plastic shell 1 and a base, the plastic shell and the base are sealed to form a cavity, and a metal inner shell 2 is sleeved in the cavity, and two static contactors are arranged in the metal inner shell. Point 3, the reciprocating drive mechanism composed of the moving contact piece 4, the coil 5 and the moving iron core, the base is provided with two lead wires 51 of the coil, and the reciprocating driving mechanism can drive the moving contact piece to move back and forth with the two The static contacts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com