Sock

A sock and sock bottom technology, applied in socks, pantyhose, clothing, etc., can solve the problems of slipping, short service life and wear of stockings, and achieve comfortable wearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

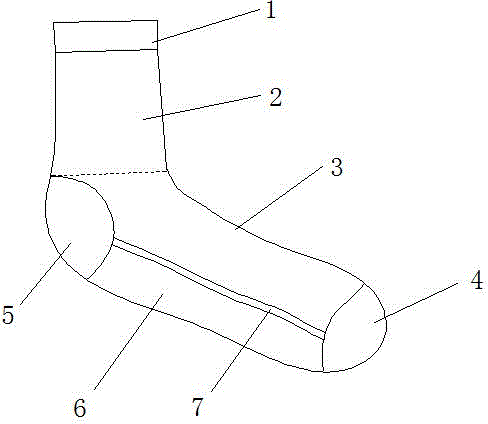

[0013] figure 1 Shown is a sock, which includes a sock toe 4, a sock heel 5, a sock bottom 6, a sock face 3, a sock tube 2 and a cuff 1, wherein the sock bottom is a thickened layer, and the thickened layer is a silk-cotton interweaving layer, The surface of the silk-cotton interweaving layer is silk and the bottom is cotton. Thickened layer and sock face 3 joints are provided with side strips 7, and side strips 7 are silk nylon interwoven strips, and the surface of silk nylon interwoven strips is nylon at the bottom of silk. The surface of the silk-cotton interweaving layer is silk and the bottom is cotton. The exact meaning is that the outer (surface) surface of the sock sole is cotton, and the inner (surface) surface of the sock sole is silk, that is, the side of the sock bottom that is in contact with the sole is cotton. The side where the sole of the sock is in contact with the sole of the foot is silk. The surface of the silk nylon interwoven strip is silk and the bott...

Embodiment 2

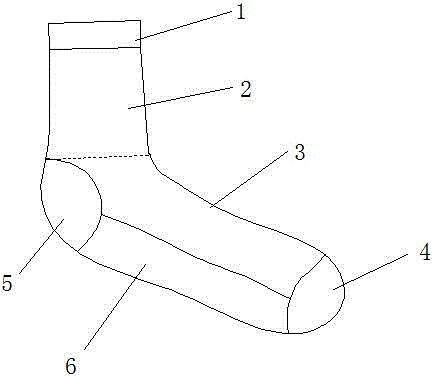

[0015] figure 2 Shown is another kind of sock, which consists of a sock toe 4, a sock heel 5, a sock bottom 6, a sock face 3, a sock tube 2 and a cuff 1, wherein the sock bottom is a thickened layer, and the thickened layer is a silk-cotton interwoven layer , the surface of the silk-cotton interweaving layer is silk and the bottom is cotton. The surface of the silk-cotton interweaving layer is silk and the bottom is cotton. The exact meaning is that the outer (surface) surface of the sock sole is cotton, and the inner (surface) surface of the sock sole is silk, that is, the side of the sock bottom that is in contact with the sole is cotton. The side where the sole of the sock is in contact with the sole of the foot is silk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com