Sandstone separator

A technology of a sand and gravel separator and a machine base, which is applied in the field of sand and gravel separators, can solve the problems of large impact force of mud water, reduced service life, and pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

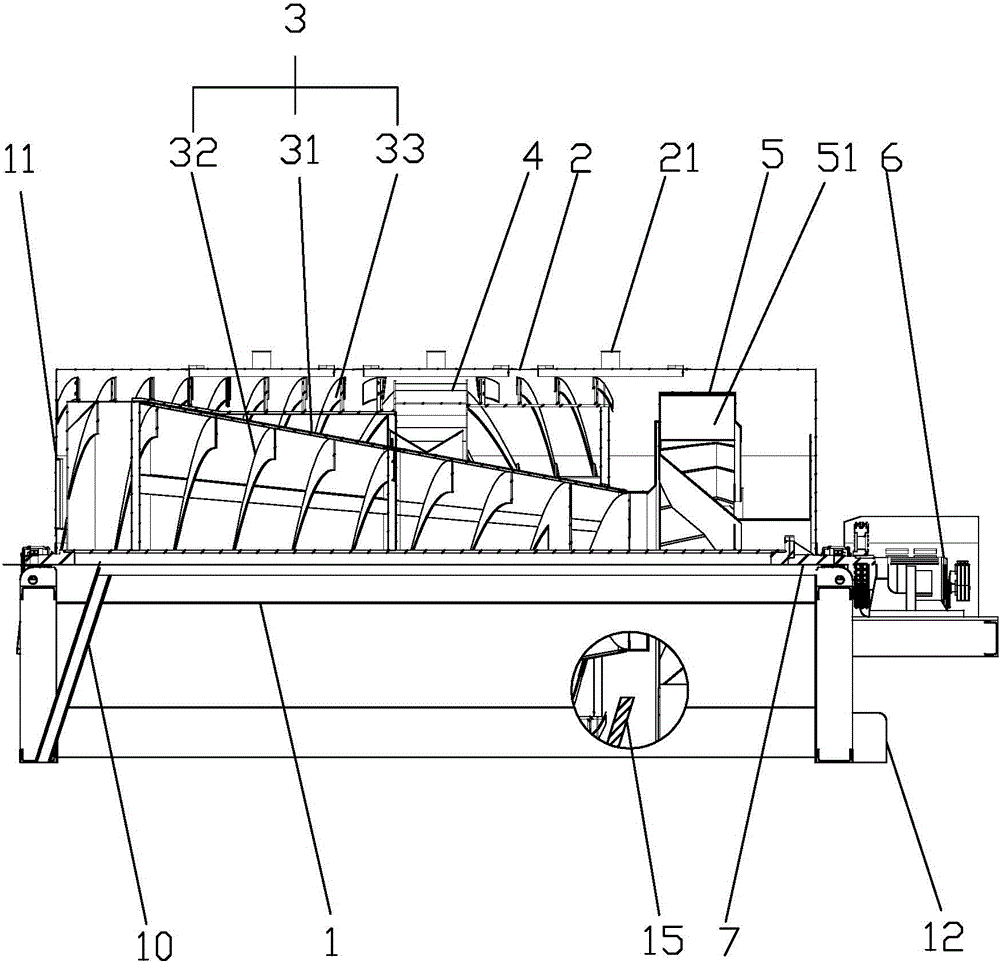

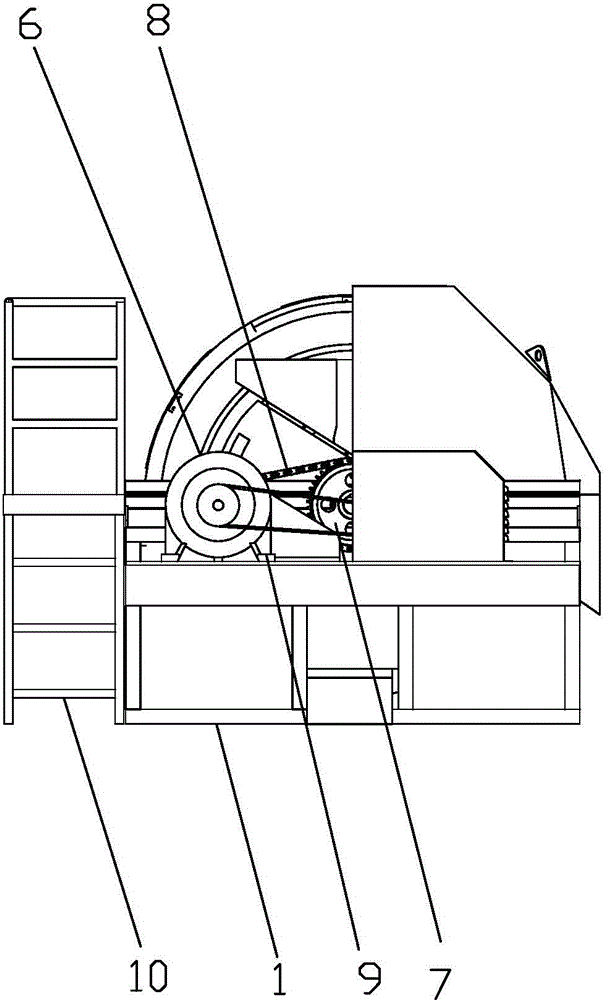

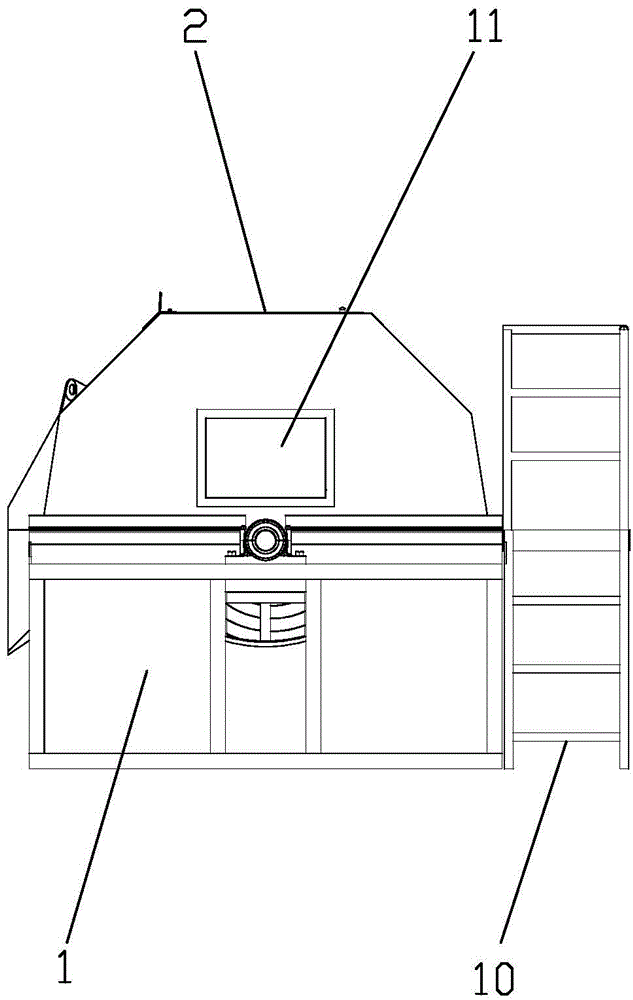

[0018] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

[0019] Such as Figure 1-5 The sand separator includes a separator base 1, a power system 6, a separator cover 2 arranged on the upper side of the separator base 1, a screening system 3 arranged in the separator base 1, a sand scraping bucket 4 and The stone transport bucket 5, the screening system 3, the sand scraping bucket 4 and the stone transport bucket 5 are respectively connected with the power system 6, and the screening system 3 includes a conical material cylinder 31, which is arranged inside the conical material cylinder 31 and The matching tapered auger 32 and the outer auger 33 arranged on the outside of the tapered barrel 31, the outer wall of the tapered barrel 31 is provided with a screen hole 311, the spiral on the tapered auger 32 The blades gradually become smaller along the advancing direction, and the spiral blades...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap