Processing method of polyester plastic parts

A technology of polyester plastics and processing methods, which is applied in the direction of metal processing equipment, manufacturing tools, accessories of tool holders, etc., can solve the problems of not being suitable for processing polyester plastic parts and affecting the processing quality, so as to ensure the quality of turning and solve the extrusion problem. Pressure problem, the effect of ensuring sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

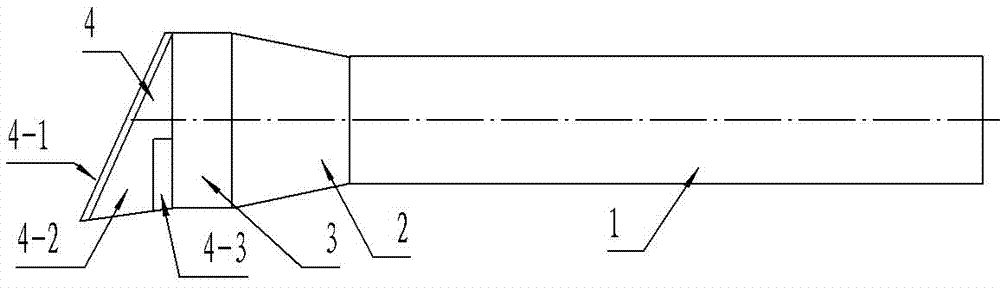

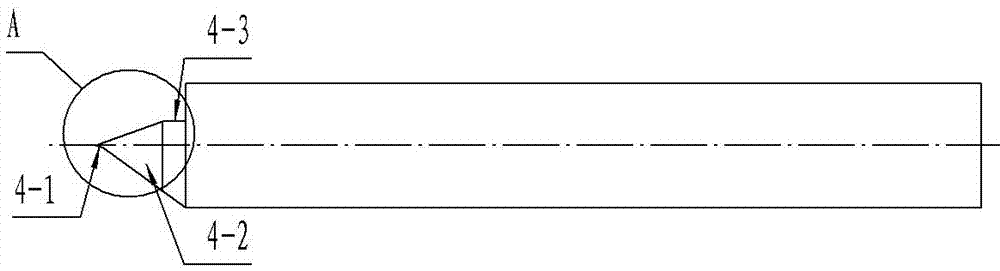

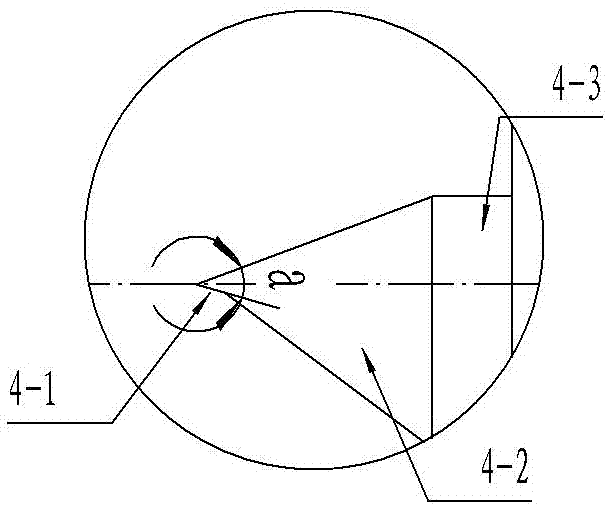

[0018] Including the use of a polyester plastic parts turning tool to process polyester plastic parts, polyester plastic parts turning tools such as figure 1 , figure 2 , image 3 As shown, it includes a cutter body 1 and a blade portion 4. The front end of the cutter body 1 is provided with a wide head 3 whose width is greater than that of the cutter body 1 to enhance the turning strength. The rear end of the wide head 3 and the cutter body 1 A connecting portion 2 is provided between them. Blade portion 4 is located at the front end of wide head portion 2, and blade portion is scalene cone 4-2, and blade portion 4 is provided with step 4-3 at the front end of wide head portion 3, and blade portion 4 is at cutting edge place 4-2. 1 The taper becomes smaller, the taper a=11° at the cutting edge of the blade portion 4, and the material of the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com