Dry-type transformer fan maintenance device

A dry-type transformer and maintenance device technology, applied in the field of power transmission and transformation, can solve problems such as time-consuming, reduce maintenance efficiency, affect production and life, etc., to ensure safe and efficient live maintenance operations, work efficiency and accuracy of operation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to facilitate the understanding of the technical content of the present invention, the technical solution thereof will be described in detail below in conjunction with specific embodiments.

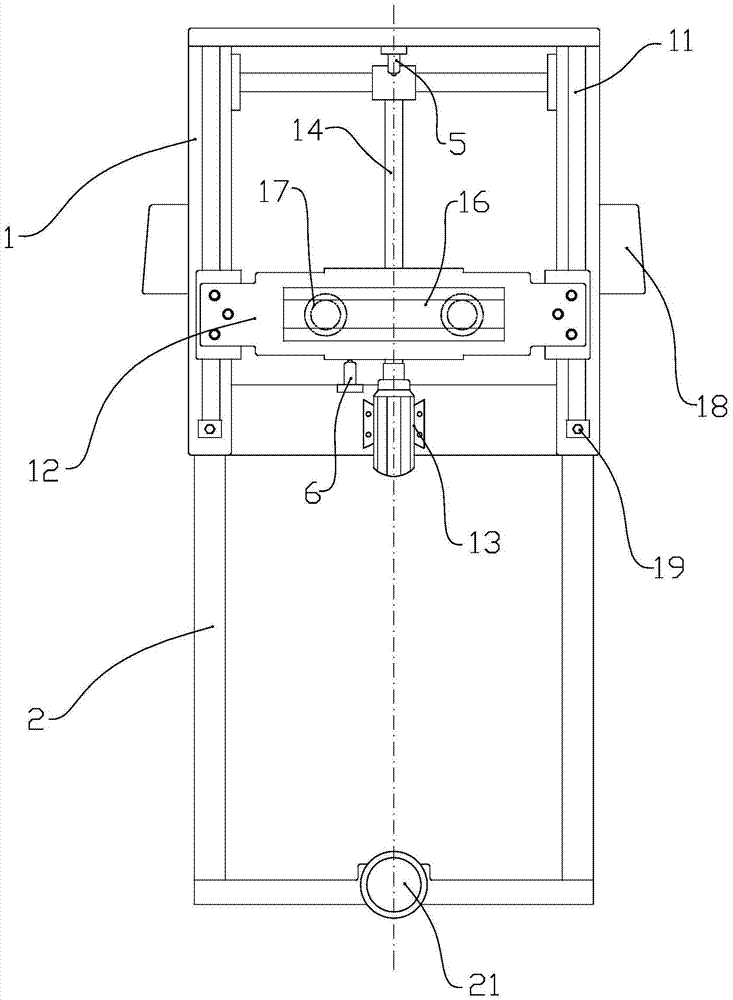

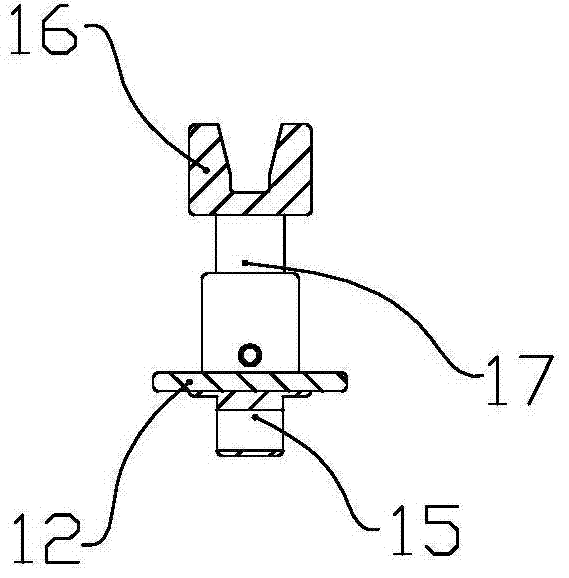

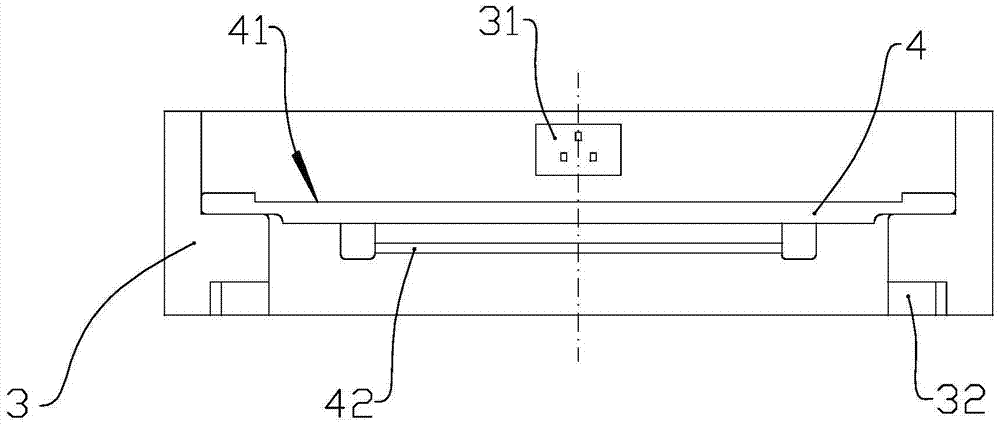

[0055] like Figure 1 to Figure 7 A dry-type transformer blower maintenance device shown includes a maintenance vehicle and a maintenance bracket. The maintenance vehicle includes a vehicle seat 1, a U-shaped sliding seat 2 and a control unit, and universal wheels are arranged at the lower end of the vehicle seat 1. The maintenance bracket includes a fan bracket 3 and a supporting plate 4 .

[0056] like figure 1 , Figure 7 As shown, the vehicle seat 1 includes two longitudinal arms arranged parallel to each other and transverse baffles arranged at the front and rear ends of the two longitudinal arms. Parallel line rails 11 are provided on the upper end surfaces of the longitudinal arms, and guide blocks 18 are respectively provided on the outer surfaces. Travel swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com