A Consolidation and Removal Construction Method of Block 0# of Ultra-Width Variable Cross-section Continuous Beam

A construction method and variable cross-section technology, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of not being able to resist unbalanced bending moments and waste materials, and achieve the effects of saving construction time, reducing costs, and improving project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

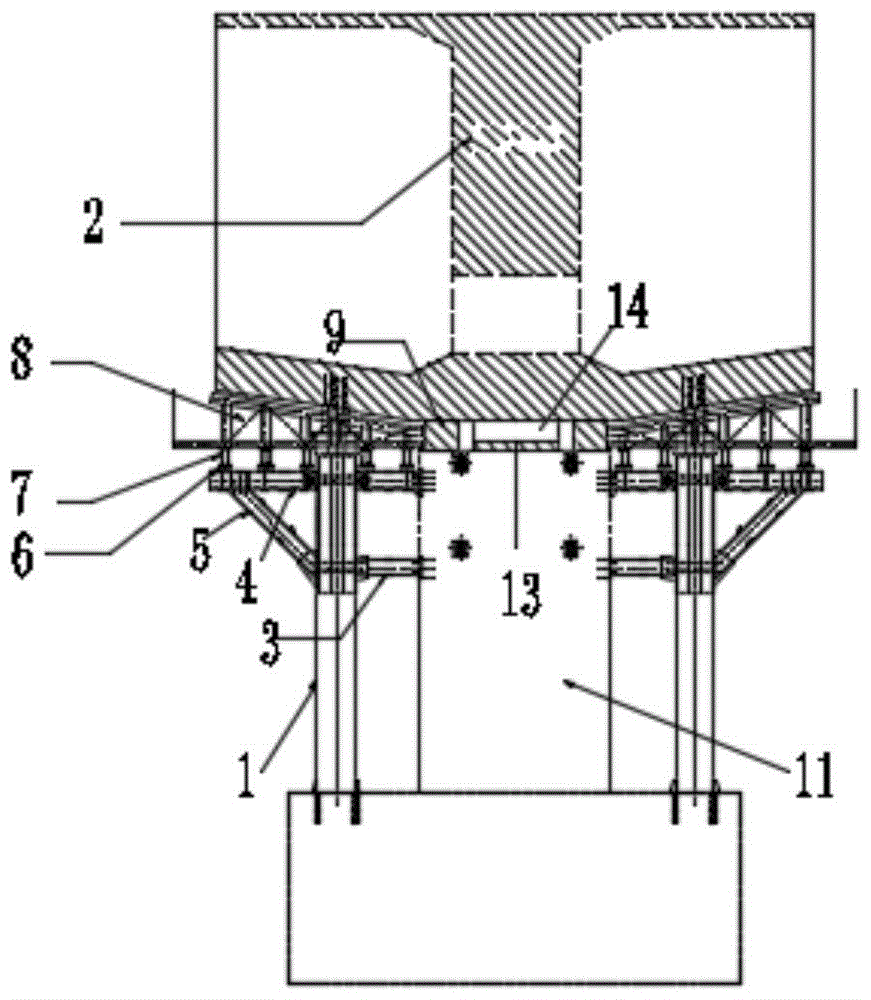

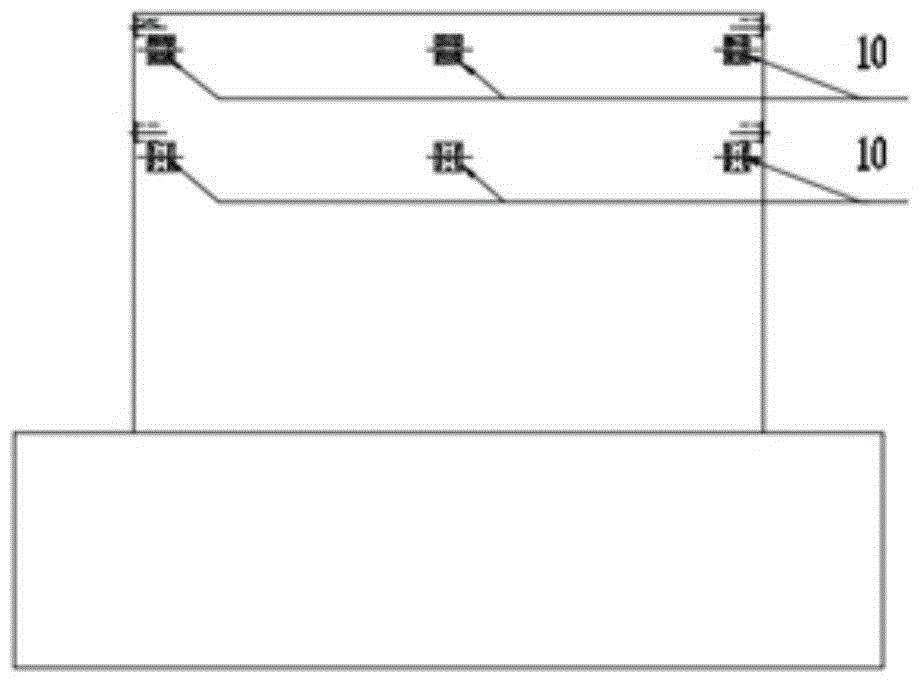

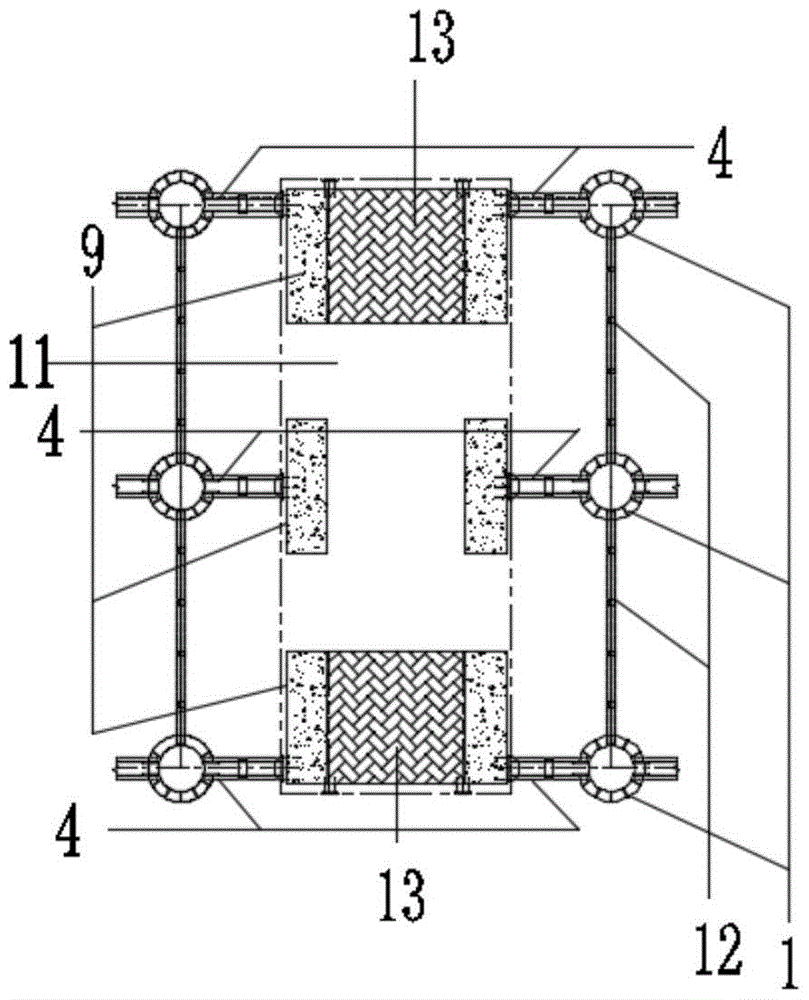

[0032] (1) A row of steel pipe columns 1 are respectively installed along the transverse bridge direction on the left and right sides of the continuous pier 11 as temporary piers, and the adjacent steel pipe columns in the same row are connected by a connecting system 12;

[0033] (2) Each steel pipe column 1 is connected to the embedded part 10 on the side wall of the continuous pier on the adjacent side respectively by welding the upper tie beam 4 and the lower tie beam 3 along the horizontal direction, and the upper tie beam 4 and the lower tie beam 3 extend to the outer side of the steel pipe column 1, and the upper tie beam 4 and the outer side of the lower tie beam 3 on the same steel pipe column 1 are fixedly connected by an inclined beam 5;

[0034] (3) On the left and right sides of the pier top of the continuous pier 11, two rows of reinforced concrete temporary consolidation blocks 9 are poured and fixed respectively along the transverse bridge direction, and each ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com