Reflective display substrate and reflective display device

A reflective display and substrate technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of many impurities in the liquid crystal layer 114, limited service life of liquid crystals, and contamination of liquid crystal solutions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

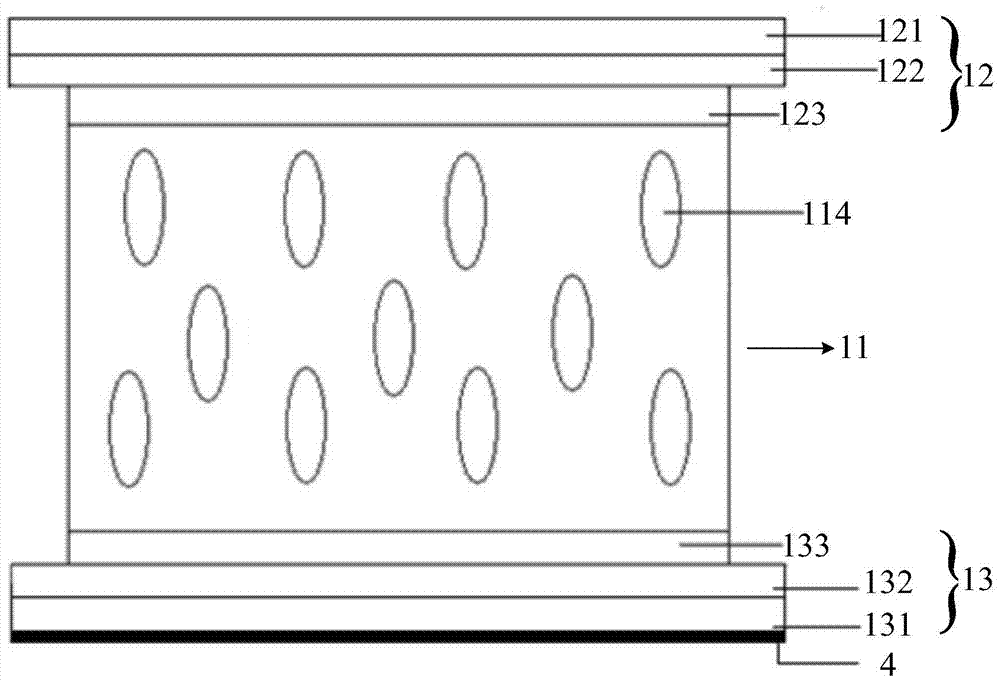

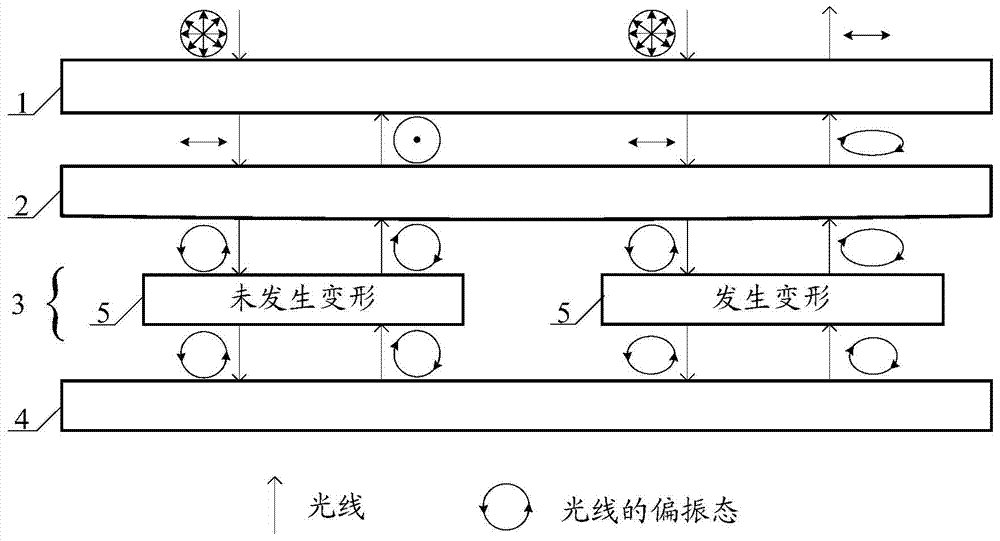

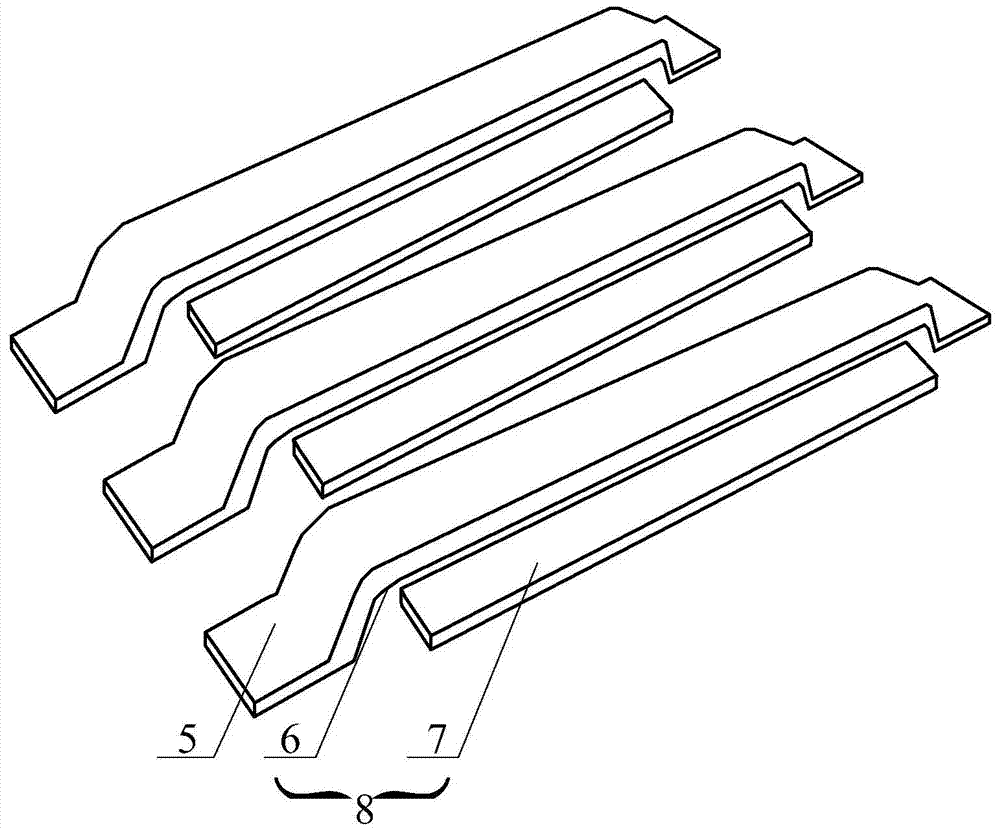

[0023] Such as figure 2 As shown, this embodiment provides a reflective display substrate, including: a reflective layer 4, a stress birefringent layer 3, a quarter-wave plate layer 2, and a polarizing layer 1 that are sequentially stacked, wherein the stress birefringent layer 3 It includes a plurality of stress birefringent sheets 5 arranged in an array. read on figure 2 After the natural light passes through the polarizing layer 1 and the quarter-wave plate layer 2, it becomes circularly polarized light. When the stress birefringent film 5 is deformed, the circularly polarized light passing through the stress birefringent film 5 becomes elliptically polarized l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com