A kind of diatomite/heavy calcium carbonate composite humidity control material and its preparation method

A technology of heavy calcium carbonate and humidity-regulating materials, applied in chemical instruments and methods, and other chemical processes, can solve the problems that the moisture absorption and desorption capacity is difficult to meet the high moisture absorption performance of humidity-controlling materials, the pore size becomes larger, and the impurity content is high. Achieve good application prospects, improve moisture absorption performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

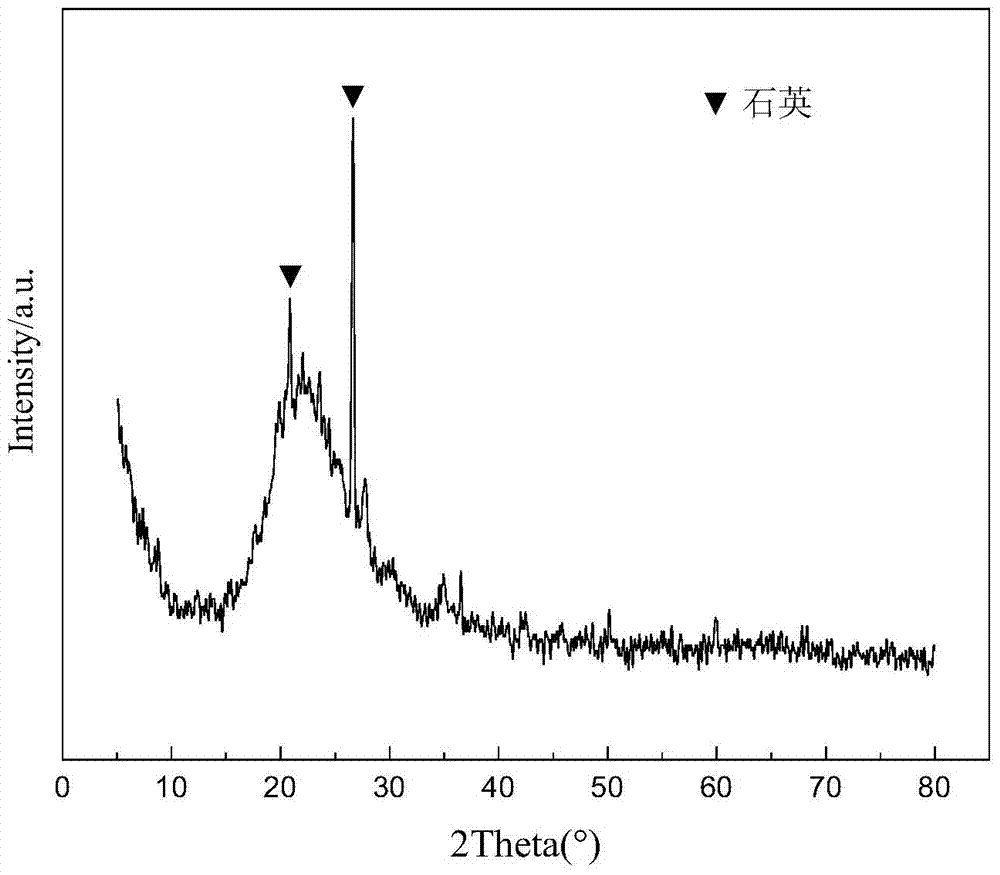

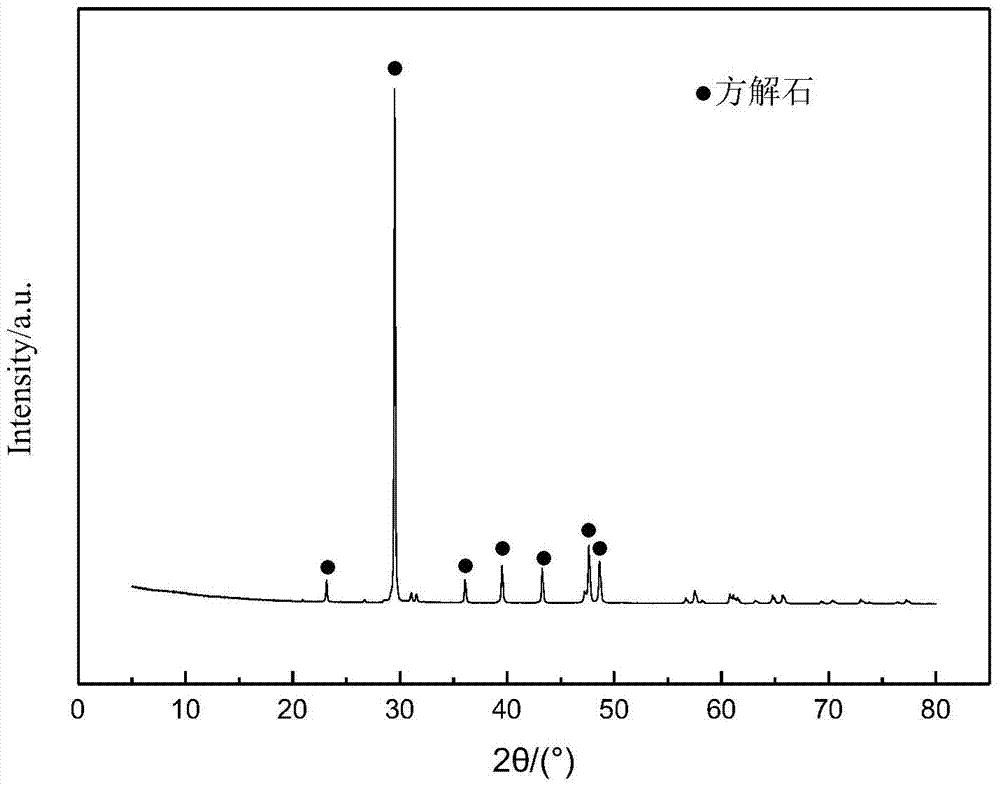

[0030] Raw material introduction: Diatomite comes from Linjiang Beifeng Diatomite Co., Ltd., the main chemical composition and content are SiO 2 86.97%, Al 2 o 3 3.76%, Fe 2 o 3 2.13%, MgO 0.23%, CaO 0.35%, particle size 200 mesh sieve remaining 2.0%; heavy calcium carbonate from Zhangjiajie Hengliang New Material Technology Co., Ltd., CaCO 3 The content is 98.26%, the particle size is 325 mesh and the remainder is 3.0%. Its main mineral component is calcite.

[0031] The preparation process steps are as follows:

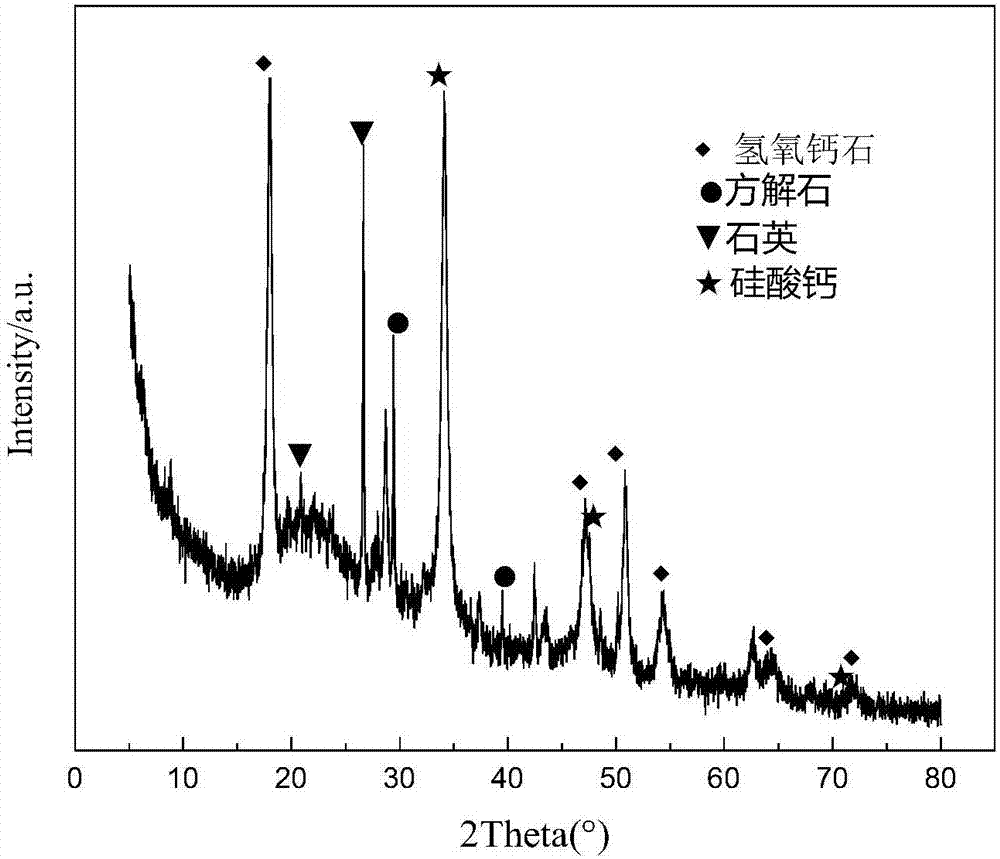

[0032] Mix diatomite and heavy calcium carbonate in a mass ratio of 1:1, mix them evenly, put them into a laboratory rotary furnace, raise the temperature to 700°C at 15°C / min, and roast at 700°C for 2.0h to prepare diatomite / Heavy calcium carbonate composite humidity control material.

[0033] A KW-TH-225Z programmable constant temperature and humidity test chamber manufactured by Dongguan Kewen Test Equipment Co., Ltd. was used to measure the moisture abso...

Embodiment 2

[0044]The same as the raw materials and process steps in Example 1, the difference is that diatomaceous earth and heavy calcium carbonate are batched in a mass ratio of 1:1, mixed uniformly, and then fed into the laboratory rotary kiln, and heated to 15°C / min. 800°C, bake at 800°C for 1.5h.

[0045] The humidity control performance, specific surface area, pore volume and pore size distribution of the sample were measured in the same way as in Example 1, and the results are listed in Table 1.

Embodiment 3

[0047] The same as the raw materials and process steps in Example 1, the difference is that diatomaceous earth and heavy calcium carbonate are batched in a mass ratio of 1:1, mixed uniformly, and then fed into the laboratory rotary kiln, and heated to 15°C / min. 650°C, bake at 650°C for 2.5h.

[0048] The humidity control performance, specific surface area, pore volume and pore size distribution of the sample were measured in the same way as in Example 1, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com