A method of using waste concrete to prepare humidity-adjusting materials

A technology of waste concrete and humidity-controlling materials, which is applied in the field of using waste concrete to prepare humidity-conditioning materials, to achieve the effects of reducing energy consumption, improving strength, and easily obtaining raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

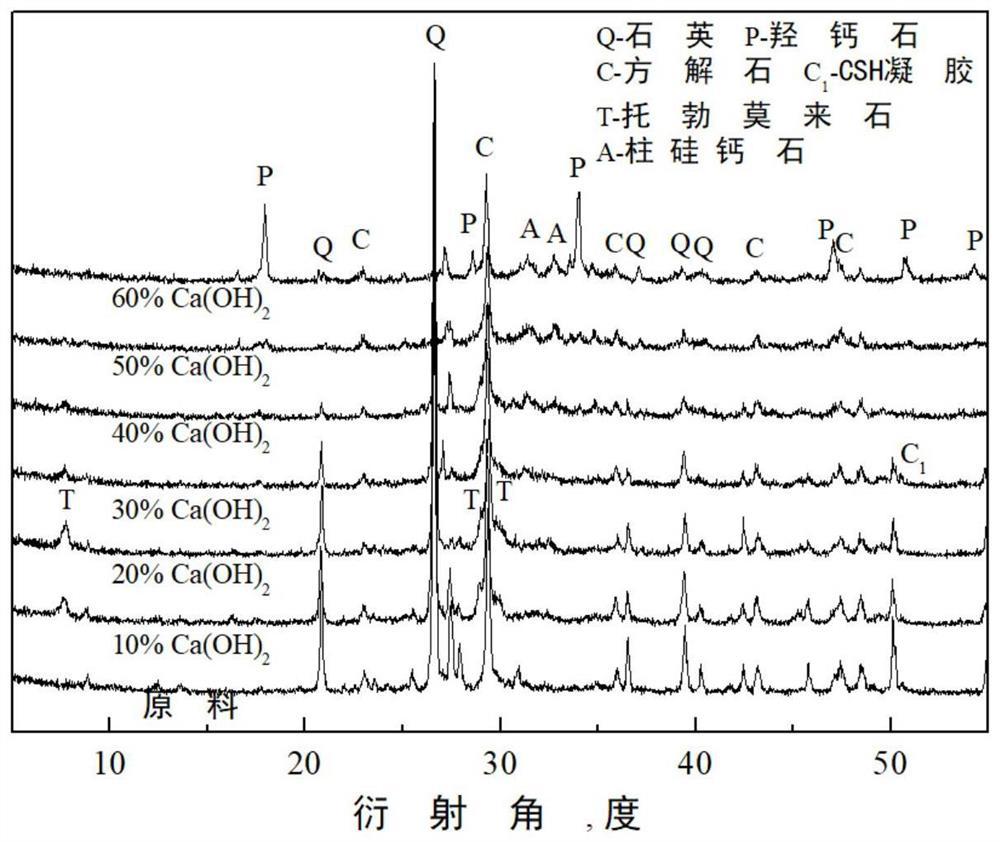

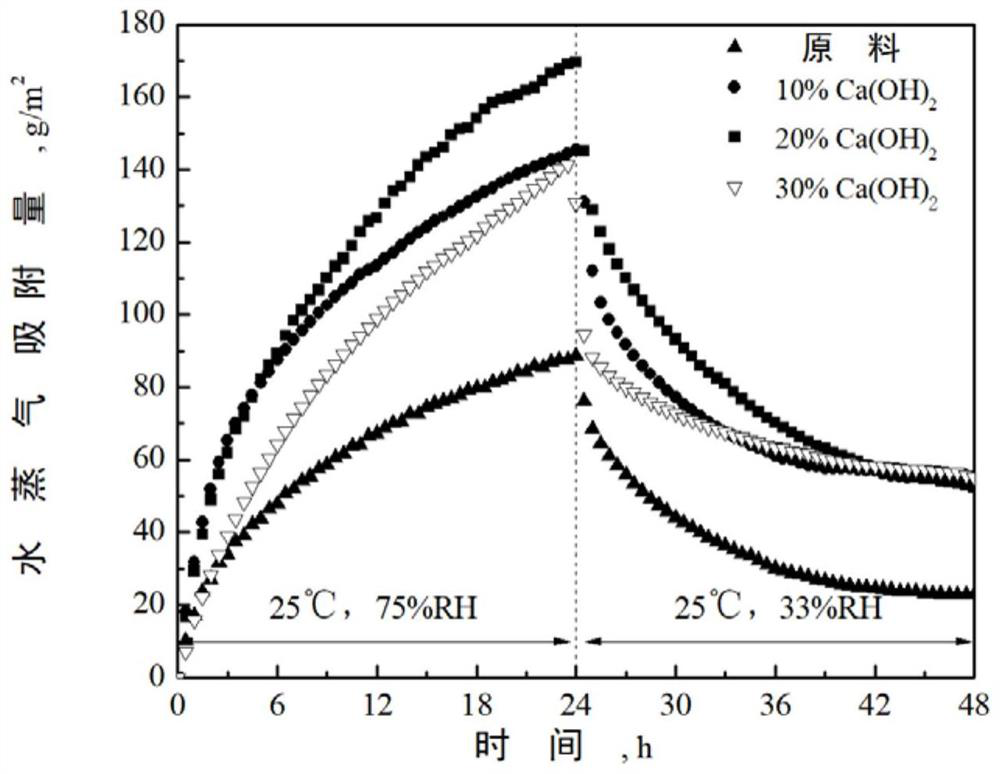

[0019] The waste concrete is first crushed and dried at 80°C, then ball milled and passed through a 100-mesh sieve. Measure waste concrete powder and slaked lime (analytically pure, China Sinopharm Reagent Co., Ltd.) in different proportions as shown in Table 1 as the main raw material according to the waste concrete powder and calcium oxide mass percentage as 100%, mix evenly, then add water, The water-mixed mass is 20% of the total mass of the above two raw materials, and stirred evenly, pressed and molded under a molding pressure of 30MPa and demolded to obtain a block sample with a size of 40mm×15mm×6mm, and finally put it into the reaction kettle , and reacted for 12 hours under the temperature condition of 200° C. to prepare the humidity-conditioning materials of Examples 1-7. Carry out three-point flexural strength test to embodiment 1-7, its result is shown in table 1. The X-ray powder diffraction analysis result of embodiment 1-7 sees figure 1 And Table 1 (only the ...

Embodiment 8-10

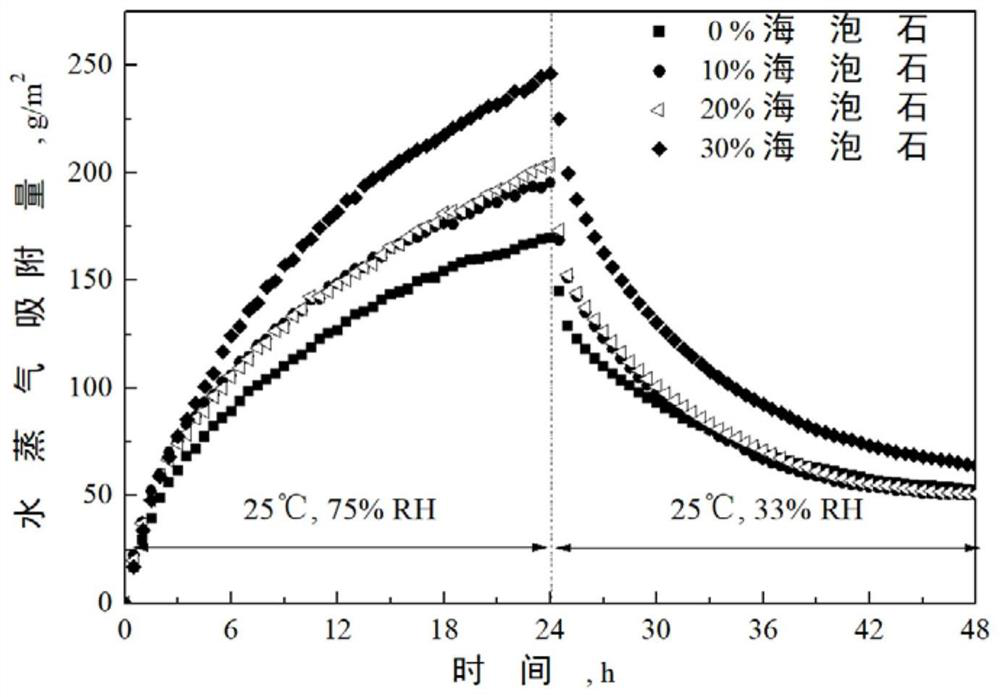

[0025] In order to further improve the humidity control performance of the bulk sample, on the basis of the main raw material proportioning (20% added amount of slaked lime) in Example 3, add 0% to 30% sepiolite powder (provided by Hunan Huajie Baoling sepiolite Technology Co., Ltd.) as modified raw materials, mix the two evenly, and finally add water accounting for 20% of the total mass and stir evenly, press and mold under a molding pressure of 30MPa and demould, and the obtained size is 40mm×15mm× A block sample of 6 mm was finally put into a reaction kettle and reacted at a temperature of 200° C. for 12 hours to prepare the humidity-conditioning materials of Examples 8-10. Because the flexural strength of Example 3 reaches 22MPa, and the amount of sepiolite added is small, the flexural strength of Examples 8-10 does not change much, and its phase composition and humidity control amount are as shown in Table 2. The humidity control effect For details, see image 3 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com