A kind of diatomite/white carbon black composite humidity control material and preparation method thereof

A humidity control material, diatomite technology, applied in the field of diatomite/white carbon black composite humidity control material and its preparation, can solve the problems of weak moisture absorption and release capacity, small hysteresis of moisture absorption and release, etc., and achieve low production cost , improved humidity control performance, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Raw material introduction: Diatomite comes from Linjiang Beifeng Diatomite Co., Ltd. The main chemical composition and content are SiO 2 86.97%, Al 2 O 3 3.76%, Fe 2 O 3 2.13%, MgO0.23%, CaO 0.35%, particle size 200 mesh sieve is less than 2.0%; sodium hydroxide comes from Beijing Chemical Plant, analytically pure; sulfuric acid comes from Sinopharm Chemical Reagent Co., Ltd., 98%wt.

[0028] The preparation process steps are as follows:

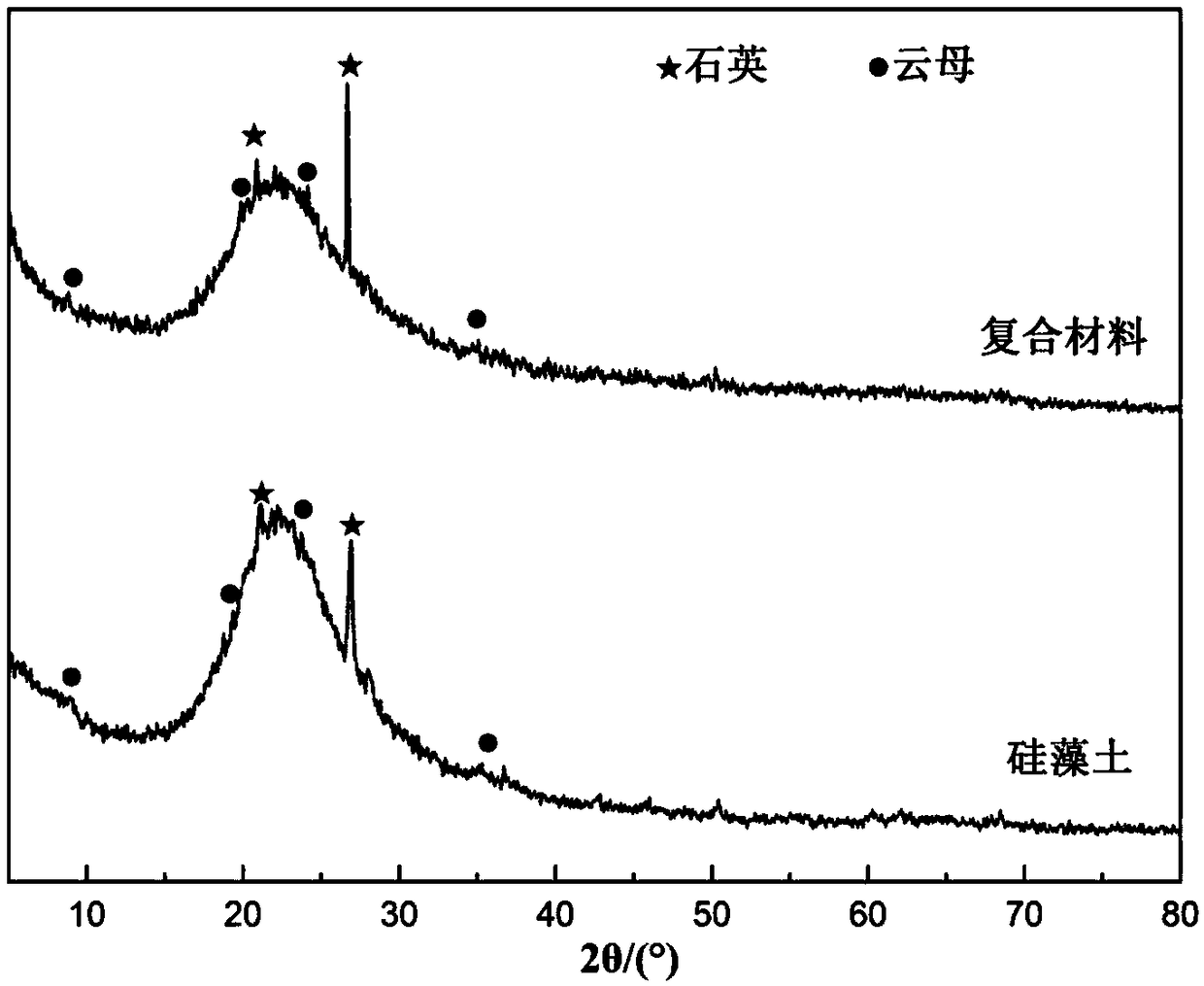

[0029] According to the mass ratio of diatomaceous earth and sodium hydroxide 1.75:1, add water to prepare a slurry with a mass concentration of diatomaceous earth of 20%, and stir at 90℃ for 30 minutes to prepare a mixed slurry containing sodium silicate and diatomaceous earth. ; Then add 60% sulfuric acid solution to the mixed pulp, acidify the sodium silicate to generate precipitated white carbon black, and aging for 20 minutes.

[0030] The KW-TH-225Z programmable constant temperature and humidity test box manufactured by Dongguan Kewen ...

Embodiment 2

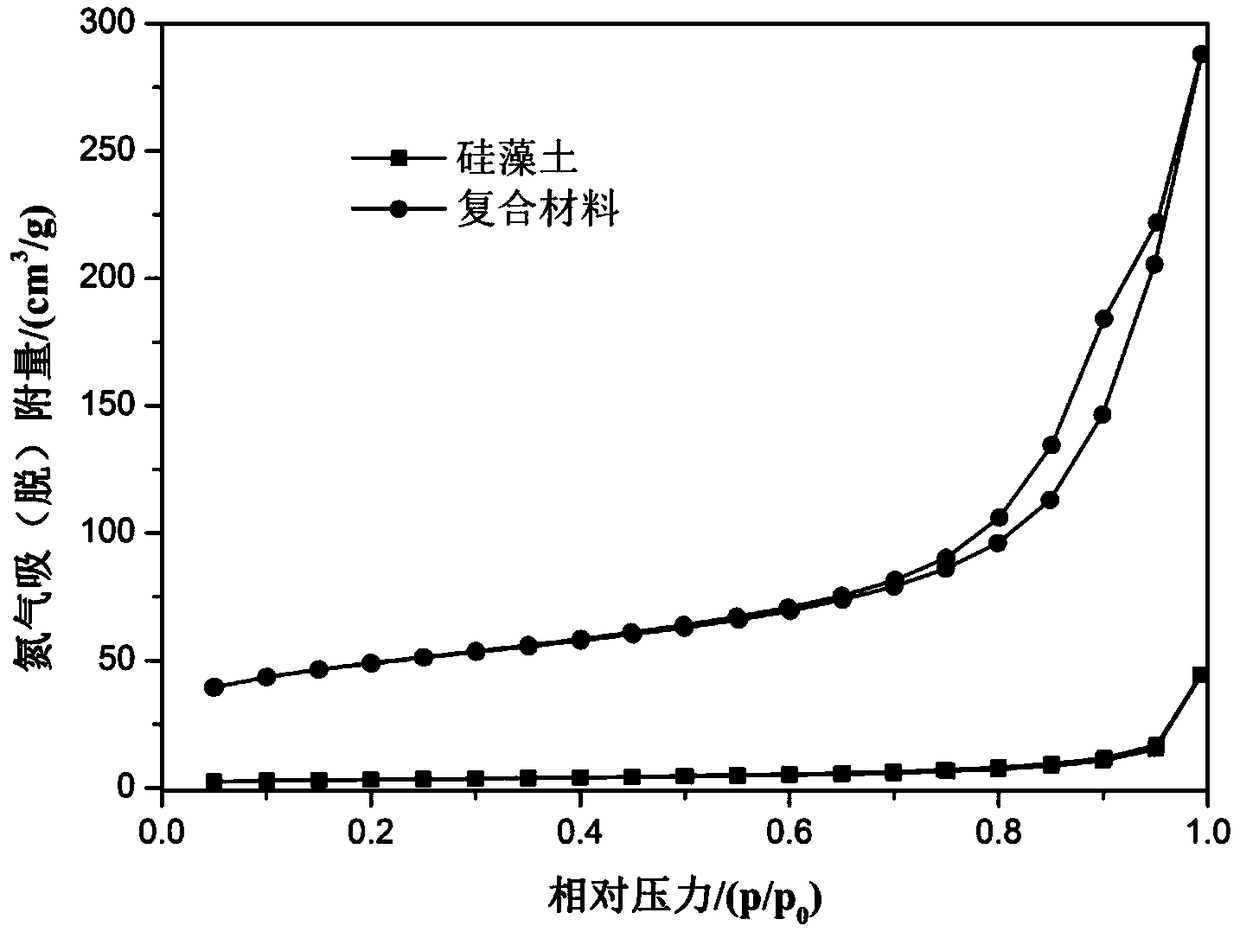

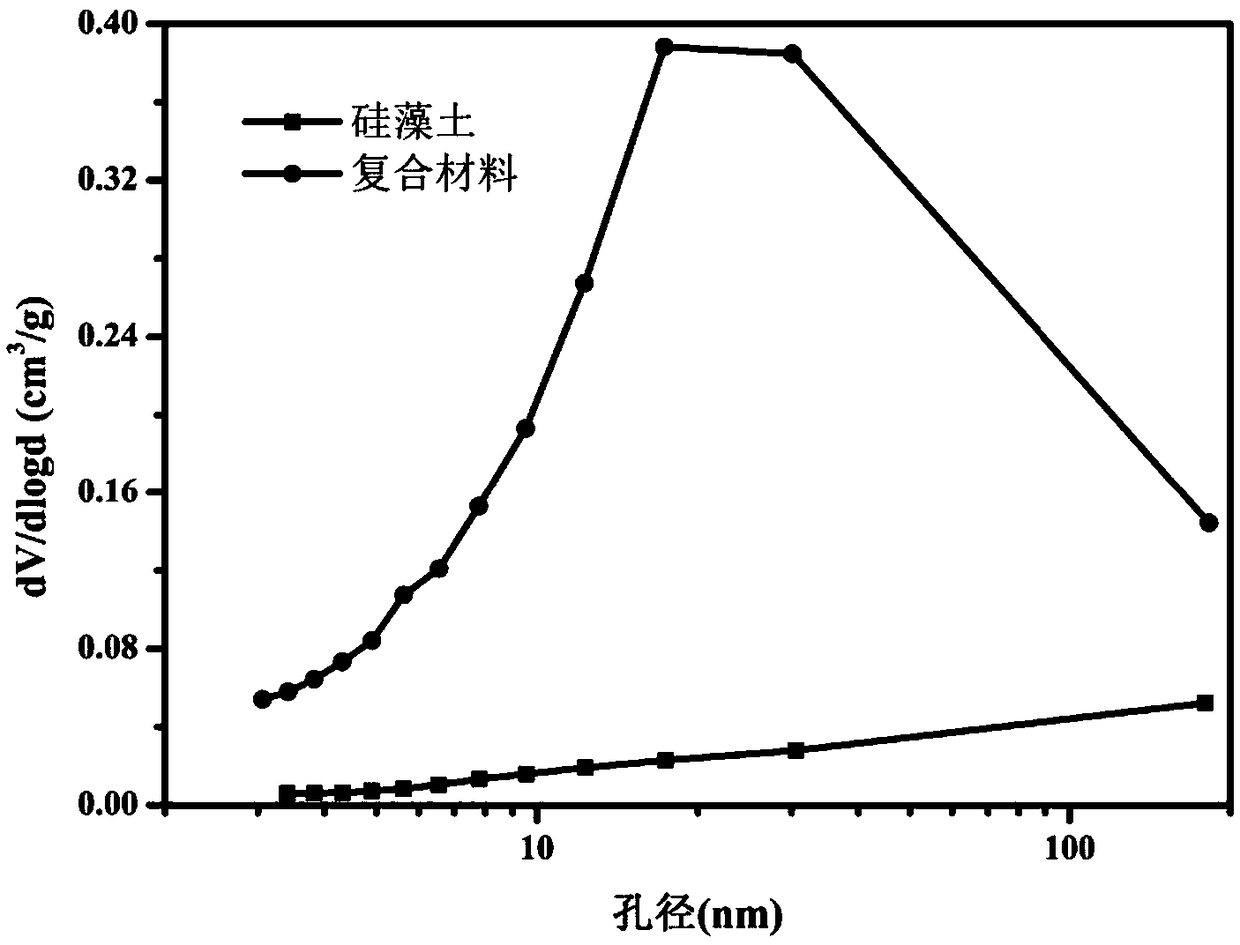

[0044] The raw materials and process steps are the same as those in Example 1. The difference is that the diatomite and sodium hydroxide are mixed with a mass ratio of 2.0:1, and water is added to make a 20% diatomite slurry at a temperature of 80°C. Stir and dissolve in alkali for 30 minutes to prepare a mixed slurry containing sodium silicate and diatomaceous earth; then add a 50% sulfuric acid solution to the mixed slurry to form precipitated white carbon black by acid precipitation. The humidity control performance, specific surface area, pore volume, and pore size distribution measurement methods of the samples of the examples are the same as those in Example 1, and the results are listed in Table 1.

Embodiment 3

[0046] The raw materials and process steps are the same as those in Example 1. The difference is that diatomite and sodium hydroxide are mixed at a mass ratio of 2.5:1, and water is added to make a diatomite slurry with a mass concentration of 25%. The temperature is 80°C. Stir and dissolve in alkali for 30 minutes to prepare a mixed slurry containing sodium silicate and diatomaceous earth; then add 50% sulfuric acid solution to the mixed slurry, and the sodium silicate is acidified to produce precipitated white carbon black. The humidity control performance, specific surface area, pore volume, and pore size distribution measurement methods of the samples in the examples are the same as those in Example 1, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com