Humidity-adjusting ceramic brick with high moisture absorption and desorption capacity and preparation method thereof

A technology of ceramic tiles and moisture content, which is applied in the field of architectural ceramics, can solve the problems of uneven humidity control performance and low flexural strength, and achieve the effects of large surface energy, high production efficiency and improved humidity control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

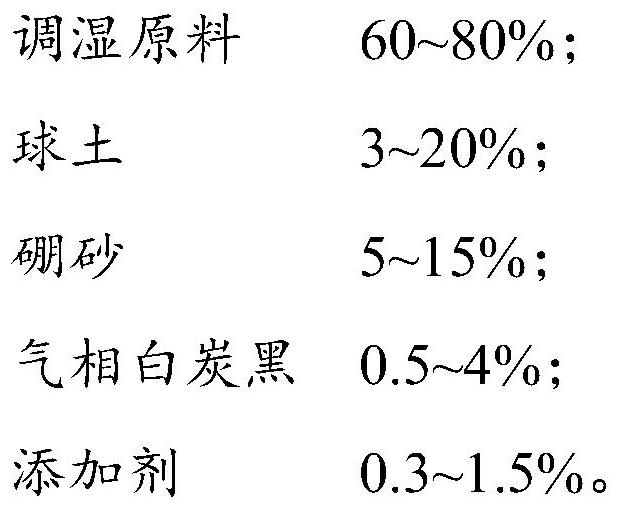

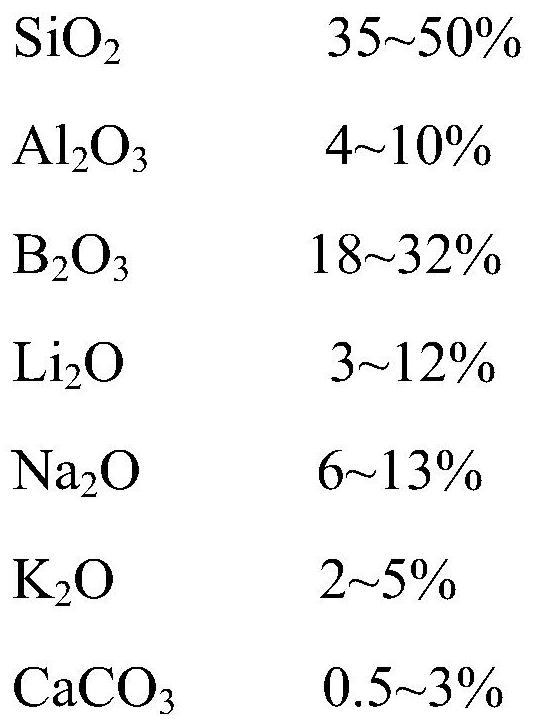

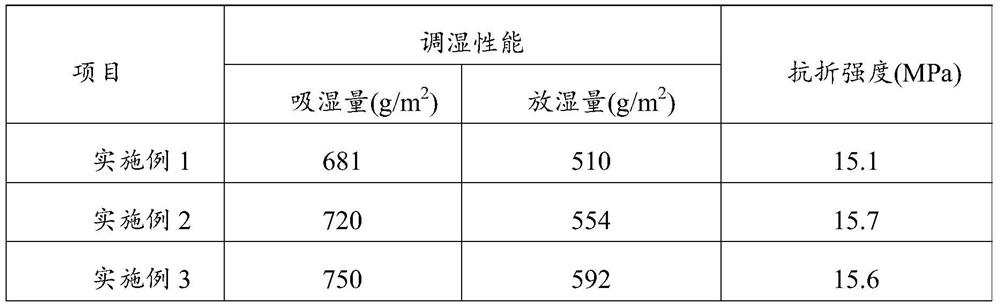

[0025] A humidity-adjusting ceramic wall tile with high moisture absorption and release capacity includes a body layer and a glaze layer. The green body layer has the following components in terms of raw material weight percentage: 30% fly ash, 30% zeolite, 20% ball clay, 15% borax, 4% fumed white carbon black, 1.0% poly Carboxylic acid sodium salt, the glaze layer includes the following chemical composition by weight percentage: 50% SiO 2 , 4% Al 2 o 3 , 32% B 2 o 3 , 3% Li 2 O, 6% Na 2 O, 2% K 2 O, 3% CaCO 3 .

[0026] Preparation:

[0027] 1) After mixing and stirring the humidity-adjusting raw materials, borax, water and additives, put them in a ball mill and grind them until the fineness is below 0.3, pass the slurry through a 250-mesh sieve, put it into a nano-sand mill, and wet-process high-energy grinding to obtain a D50 greater than 0.2 microns, less than 0.35 microns, ultrafine slurry A with a solid content of 55%;

[0028] 2) Mix and stir the slurry ball ...

Embodiment 2

[0033] A humidity-adjusting ceramic wall tile with high moisture absorption and release capacity includes a body layer and a glaze layer. The green body layer has the following components by weight percentage of raw materials: 80% volcanic ash, 3% ball clay, 13% borax, 2.5% fumed white carbon black, 1.5% fairy water, and the glaze layer is Percentages include the following chemical composition: 35% SiO 2 , 10% Al 2 o 3 , 32% B 2 o 3 , 12% Li 2 O, 6% Na 2 O, 4.5% K 2 O, 0.5% CaCO 3 .

[0034] Preparation:

[0035] 1) After mixing and stirring the humidity-adjusting raw materials, borax, water and additives, put them in a ball mill and grind them until the fineness is below 0.3, pass the slurry through a 250-mesh sieve, put it into a nano-sand mill, and wet-process high-energy grinding to obtain a D50 greater than 0.1 micron, less than 0.2 micron, ultrafine slurry A with a solid content of 50%;

[0036] 2) Mix and stir the slurry ball soil, fumed silica and water, and...

Embodiment 3

[0041]A humidity-adjusting ceramic wall tile with high moisture absorption and release capacity includes a body layer and a glaze layer. The green body layer has the following components in terms of raw material weight percentage: 40% pozzolan, 34% pumice, 14% ball clay, 10% borax, 0.5% fumed white carbon black, 1.0% fairy water and 0.5% % sodium tripolyphosphate, the glaze layer includes the following chemical composition by weight percentage: 45% SiO 2 , 8% Al 2 o 3 , 25% B 2 o 3 , 10% Li 2 O, 6% Na 2 O, 5% K 2 O, 1% CaCO 3 .

[0042] Preparation:

[0043] 1) After mixing and stirring the humidity-adjusting raw materials, borax, water and additives, put them in a ball mill and grind them until the fineness is below 0.3, pass the slurry through a 250-mesh sieve, and put it into a nano-sand mill for wet high-energy grinding to obtain a D50 of less than 0.1 micron, 50% solid content superfine slurry A;

[0044] 2) Mix and stir the slurry ball soil, fumed silica and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com