A kind of aluminum oxide/diatomite composite humidity control material and its preparation method

A technology for humidity control material and diatomite, which is applied in chemical instruments and methods, heating methods, air conditioning systems, etc., can solve the problems of small moisture absorption and release lag, difficult to meet the requirements of high moisture absorption capacity, etc., and achieves low production cost, Good application prospect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Raw material introduction: Diatomite filter aid comes from Linjiang Xinghui Filter Aid Co., Ltd., the main chemical composition and content are SiO 2 93.01%, Al 2 o 3 1.33%, Fe 2 o 3 1.37%, MgO 0.11%, CaO 0.25%, loss on ignition 0.77%, whiteness 88%, particle size 200 mesh sieve remaining 2.2%.

[0025] The preparation process steps are as follows:

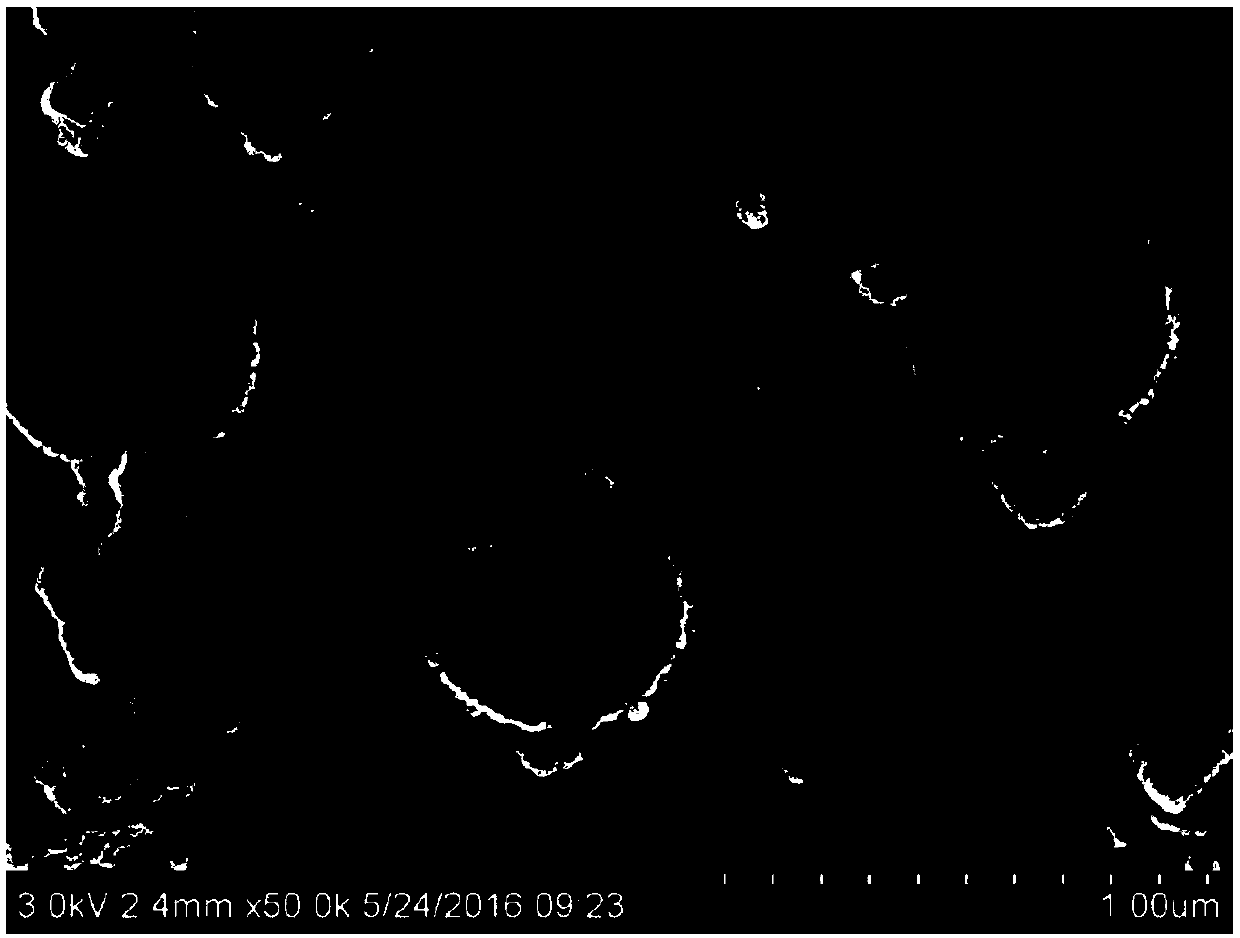

[0026] Mix 10g of diatomite filter aid with crystalline aluminum chloride, ammonium carbonate, and absolute ethanol at a mass ratio of 1:2:2:15, mix them uniformly, and put them into a laboratory reactor, and react hydrothermally at 180°C After 12 hours, filter, wash, and dry, put it into a laboratory rotary tube furnace and roast at 800°C for 4 hours to prepare alumina / diatomaceous earth filter aid composite humidity-controlling material.

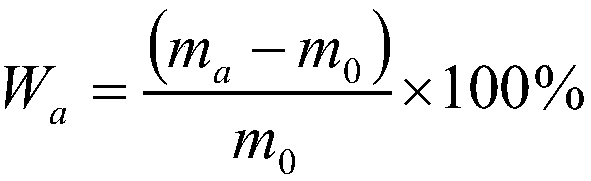

[0027] A KW-TH-225Z programmable constant temperature and humidity test chamber manufactured by Dongguan Kewen Test Equipment Co., Ltd. was used to measure the moisture absorption ...

Embodiment 2

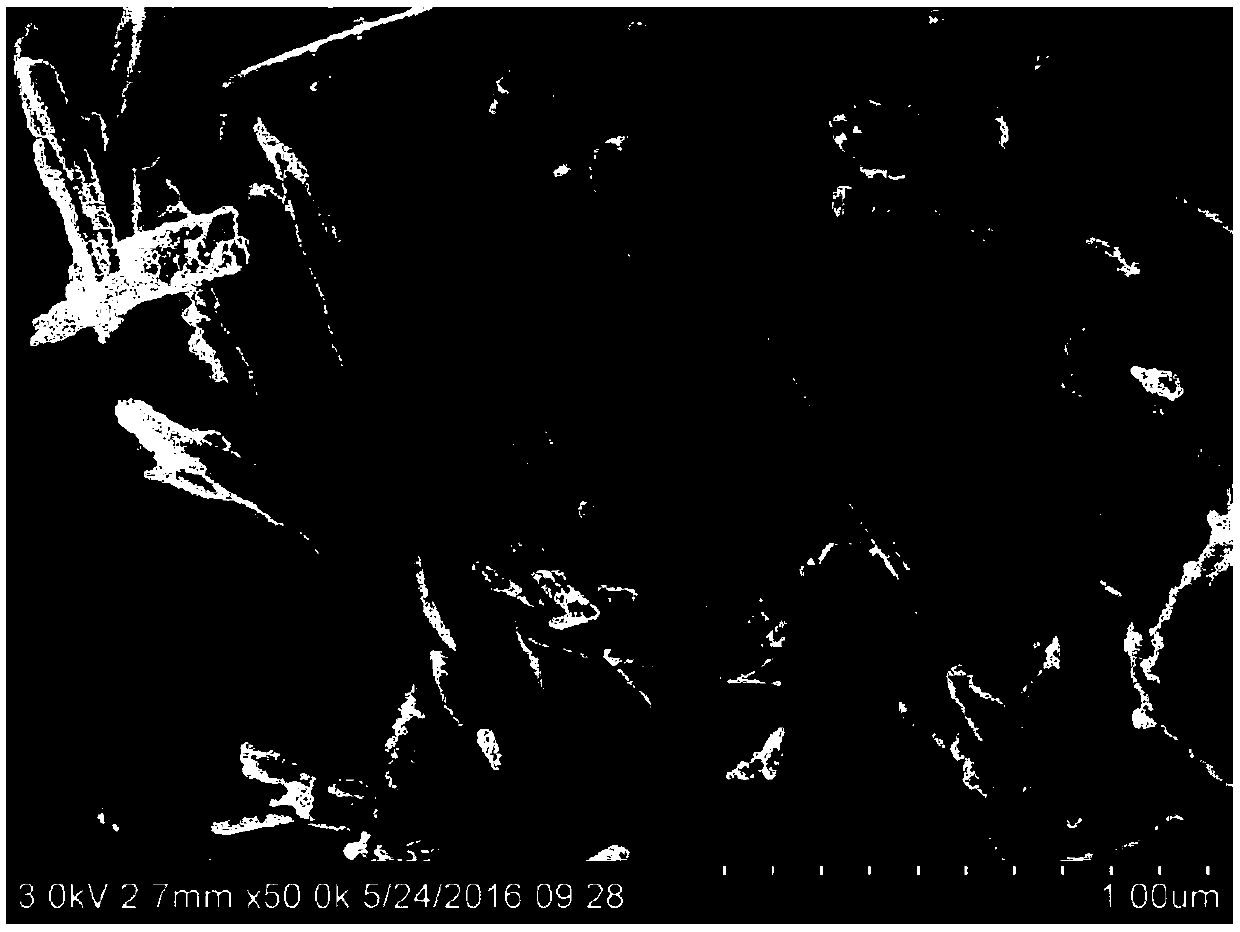

[0043] The raw materials and process steps are the same as those in Example 1, except that diatomaceous earth, crystalline aluminum chloride, ammonium carbonate, and absolute ethanol are dosed in a mass ratio of 1:2:3:17, and the hydrothermal temperature is 150°C , The hydrothermal time is 16h, the calcination temperature is 750℃, and the calcination time is 4.5h.

[0044] The humidity control performance, specific surface area, pore volume, pore size distribution and whiteness measurement method of the sample are the same as in Example 1, and the results are listed in Table 1.

Embodiment 3

[0046]The process steps are the same as in Example 1, except that the raw material used is diatomite after physical beneficiation, diatomite and crystalline aluminum chloride, ammonium carbonate, dehydrated alcohol according to 1:2:2:18 The mass ratio ingredients, the hydrothermal temperature is 210°C, the hydrothermal time is 8h, the roasting temperature is 650°C, and the roasting time is 3.5h.

[0047] Raw material introduction: Diatomite concentrate comes from Linjiang Beifeng Diatomite Co., Ltd. in Jilin Province. The main chemical composition and content are SiO 2 90.25%, Al 2 o 3 1.23%, Fe 2 o 3 0.44%, MgO 0.10%, CaO 0.01%, loss on ignition 7.74%, whiteness 81%, particle size 200 mesh sieve remaining 1.7%.

[0048] The humidity control performance, specific surface area, pore volume, pore size distribution and whiteness measurement method of the sample are the same as in Example 1, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com