Novel supporting integrated lower knife rest

A one-piece, tool holder technology, applied in packaging machines, packaging, transportation and packaging, etc., can solve the problems of complex structure of the lower tool holder, easy deformation and dislocation, poor adjustability, etc., to solve deformation and dislocation, not easy to deviate, simple effect design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

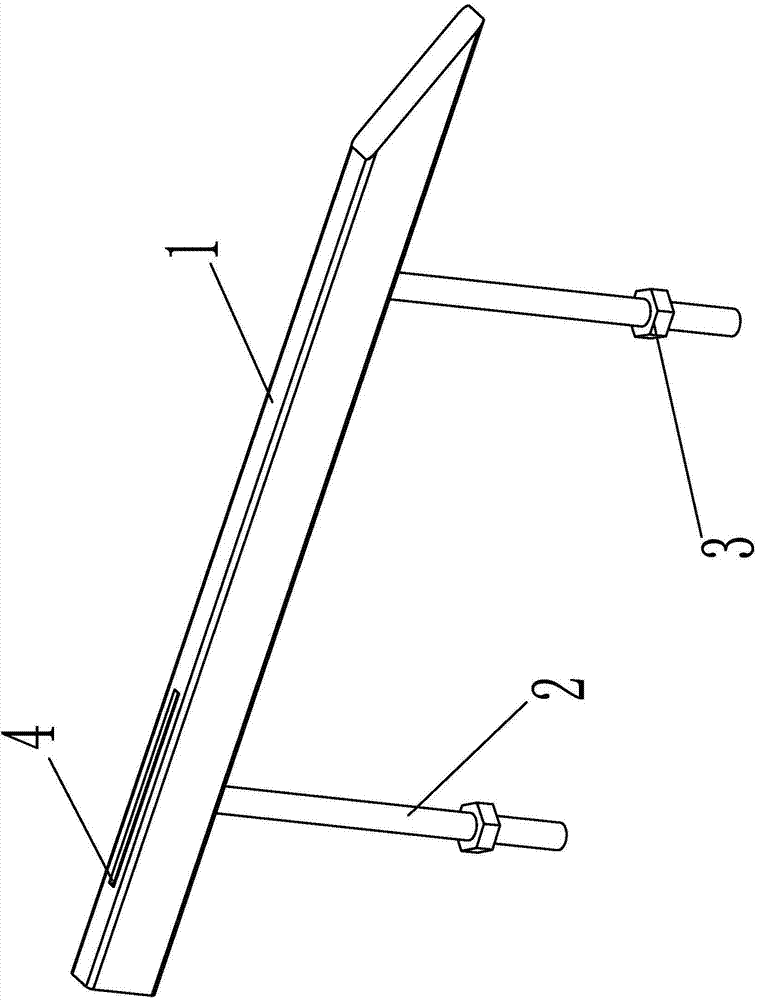

[0009] like figure 1 As shown, the technical solution adopted by the present invention is: a new type of supporting integrated lower tool holder, a bolt support rod 2 is respectively welded on the left and right ends of the bottom surface of the support square tube 1, and each bolt support rod 2 is close to the bottom position. An adjustable bolt 3 is provided, and an elongated cutting edge 4 is milled on one end of the upper surface of the supporting square tube 1 .

[0010] Through the above settings, when the present invention works, the support square tube 1 is the main body, and two bolt support rods 2 are added below, the design is simple to ensure good adjustability, and the cutting edge 4 is directly milled on the support square tube 1, avoiding The problem of cutting deviation caused by the inconsistency of the lower knife rest and the support rod of the cutter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com