Wheel type fork loader

A wheeled fork loader and fork loader technology are applied in the directions of lifting devices, earth movers/shovels, mechanically driven excavators/dredgers, etc., which can solve the problem of low loading and unloading efficiency, practicability to be improved, and insufficient action. problems such as smoothness and stability, to achieve the effects of improved efficiency, stable mechanism, and flexible and smooth movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

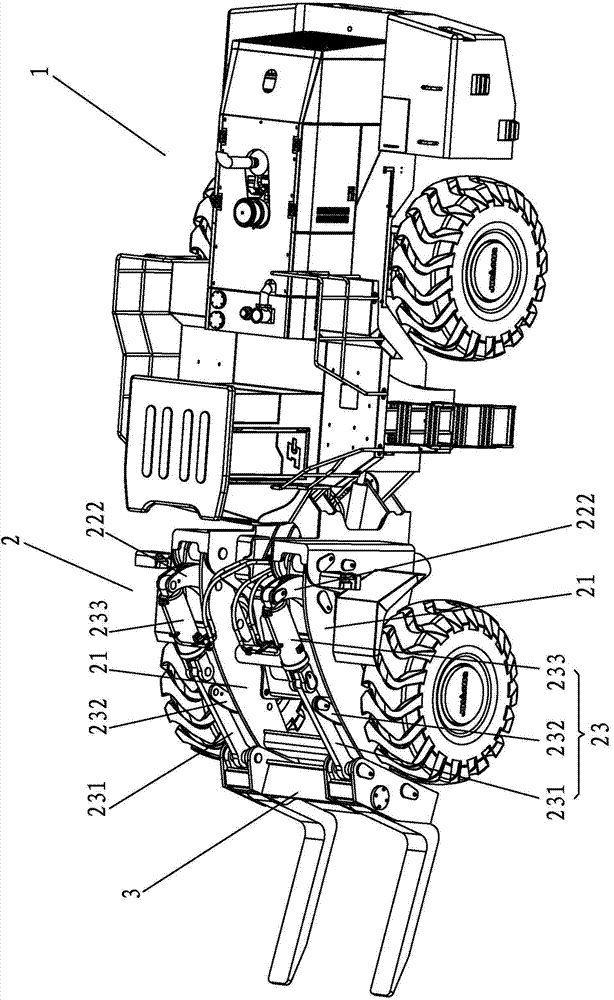

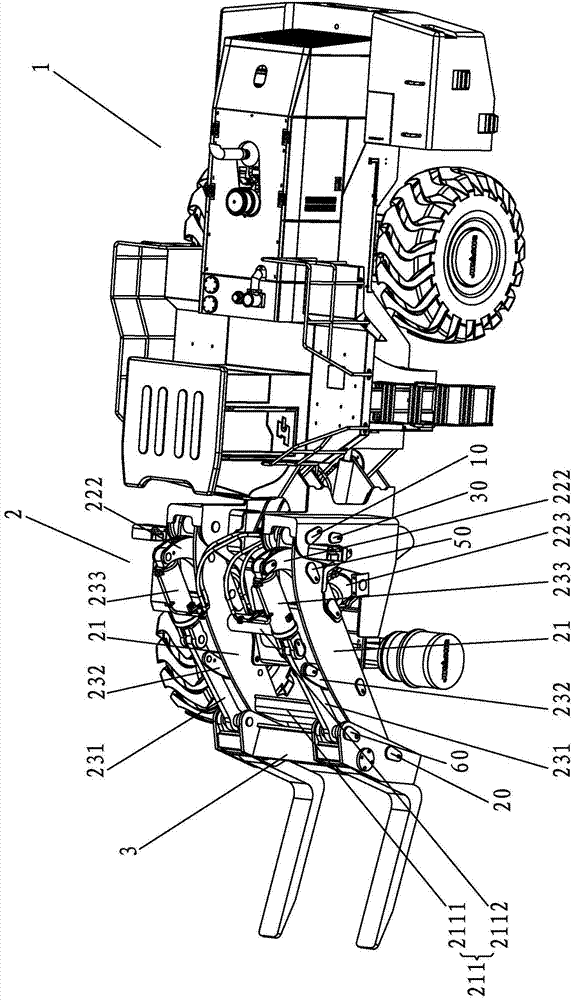

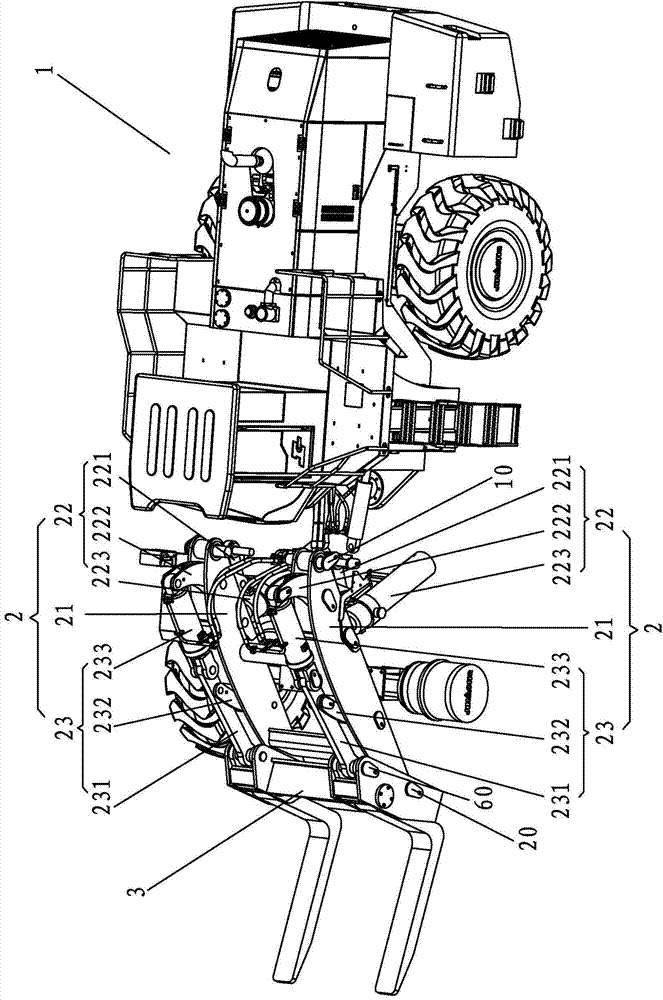

[0039] A kind of wheel type fork loader of the present invention, as Figure 1-5 As shown, it includes a forklift machine main body 1, a bending and extending driving arm mechanism 2 and a loading device 3.

[0040] The flexion and extension driving arm mechanism 2 is connected with the forklift main body 1 in a manner driven by the forklift main body 1, and the loading device 3 is arranged on the free end of the flexion and extension driving arm mechanism 2, and is driven by the flexion and extension driving arm mechanism 2; the flexion and extension driving arm mechanism 2 includes one end The main driving arm 21 connected with the forklift main body 1 and the other end connected with the loading device 3, the main driving arm 21 has an inner end pivotally connected with the forklift main body 1, and an outer end pivotally connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com