Heavy anti-vibration pipe clamp

An anti-vibration pipe and pipe clamp technology, applied in the direction of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of pipe fatigue, pipe mixing vibration, easy to cause accidents, etc., to improve the stability and prolong the use. Longevity and effect of improving anti-vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

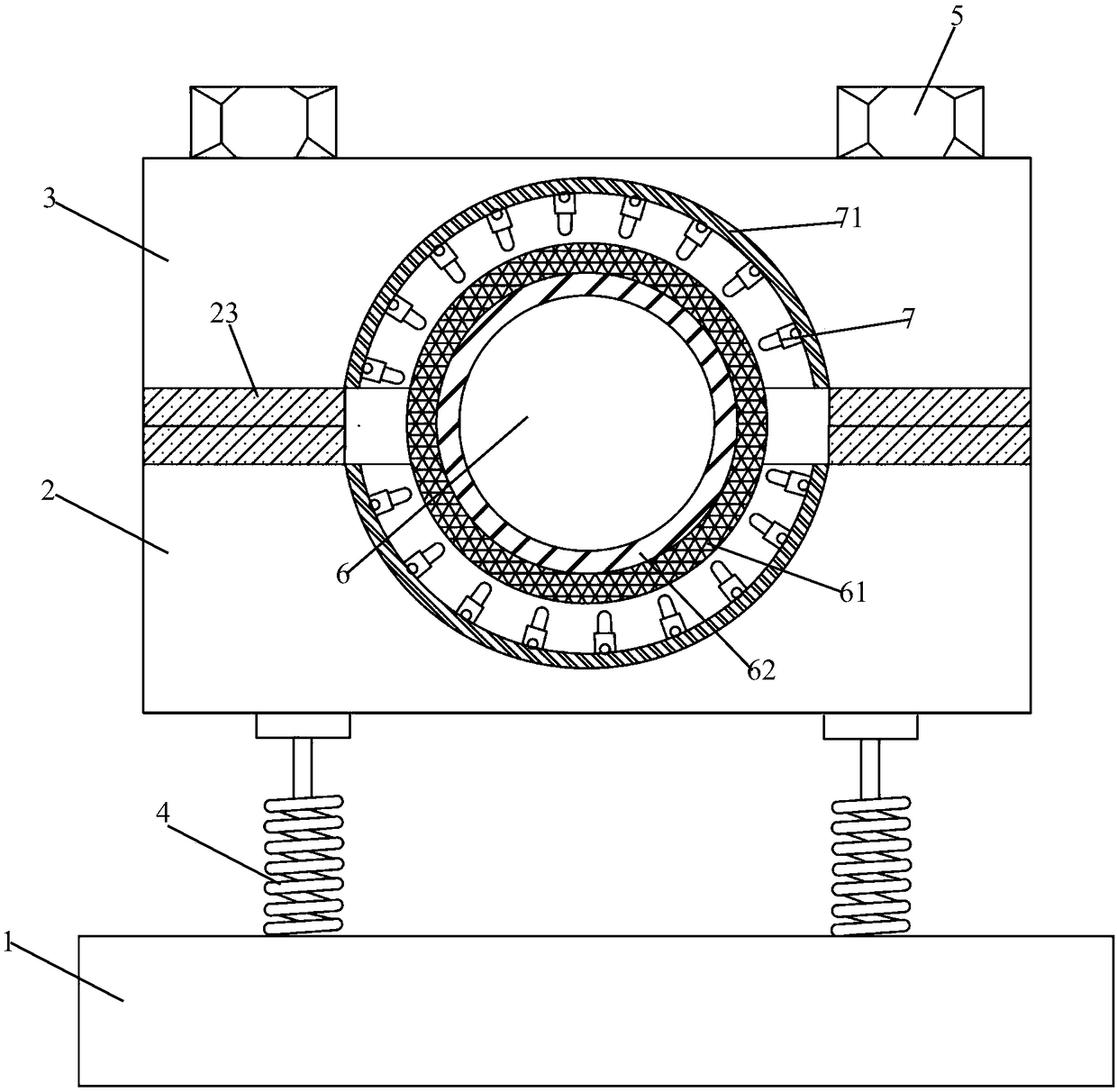

[0035] Embodiment 1: A heavy-duty shock-proof pipe clamp disclosed in the embodiment of the present invention includes a base 1, a lower pipe clamp 2 and an upper pipe clamp 3 sequentially connected to the base 1, and the base 1 is evenly connected to the base 1 through a plurality of shock absorbers 4. The bottom end of the lower pipe clamp body 2 is connected, the lower pipe clamp body 2 and the upper pipe clamp body 3 are connected by bolts 5, and a pipe clamp hole 6 is formed, and an anti-vibration device is arranged on the inner wall of the pipe clamp hole 6, and the anti-vibration device includes The rubber ring 61 connected with the inner wall of the pipe clamp hole 6 and the shockproof plate 62 connected with the rubber ring 61, one side of the rubber ring 61 is provided with threads, and is threaded with the inner wall of the pipe clamp hole 6, and the other side is provided with a groove, and A bump is provided in the groove, and the anti-vibration plate 62 is matched...

Embodiment 2

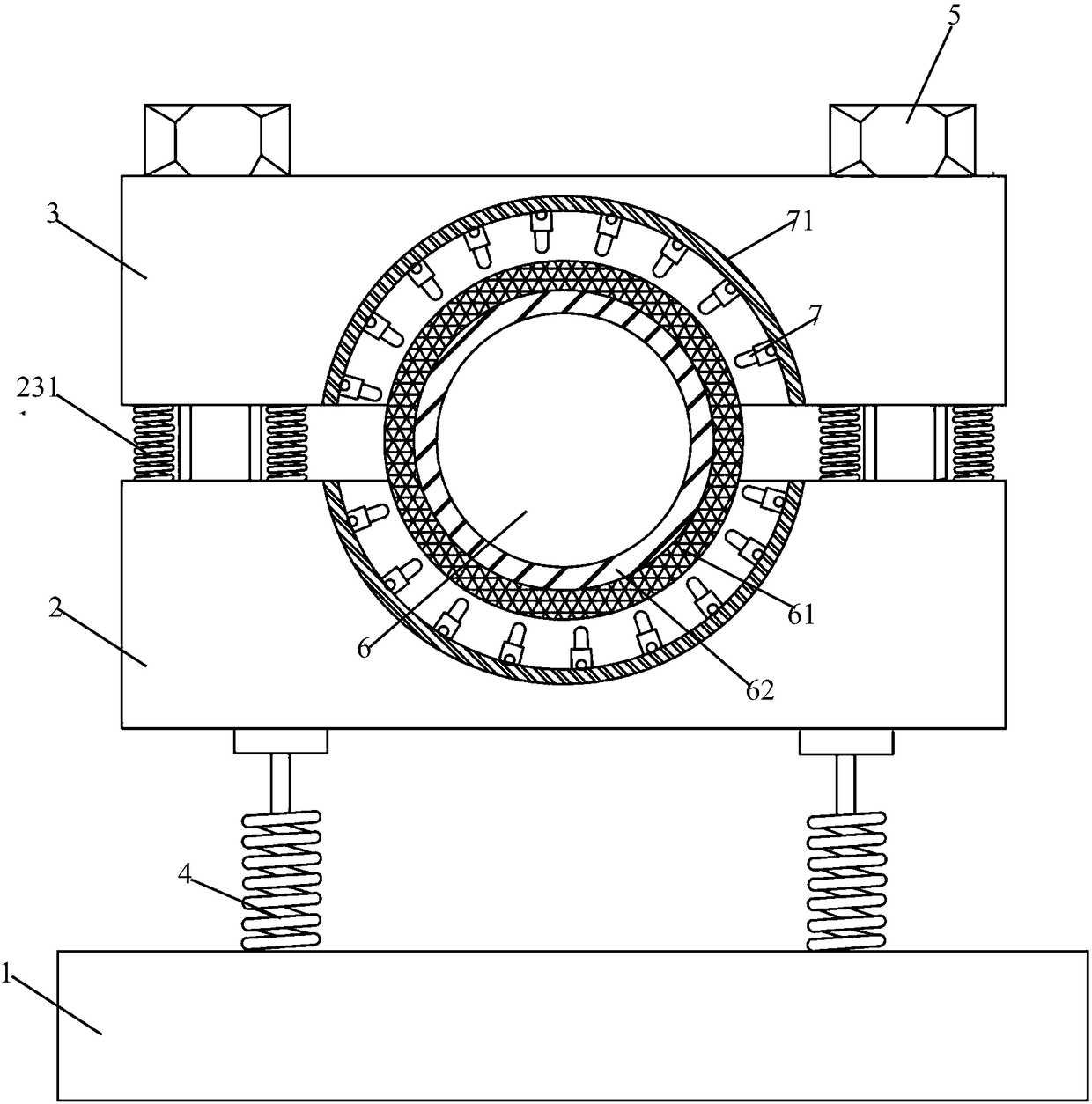

[0036]Embodiment 2: A heavy-duty shockproof pipe clamp disclosed in the embodiment of the present invention includes a base 1, a lower pipe clamp body 2 and an upper pipe clamp body 3 sequentially connected to the base 1, and the base 1 is uniformly connected to the base 1 through a plurality of shock absorbers 4. The bottom of the lower pipe clamp body 2 is connected, the lower pipe clamp body 2 and the upper pipe clamp body 3 are connected by bolts 5, and a pipe clamp hole 6 is formed, and an anti-vibration device is arranged on the inner wall of the pipe clamp hole 6, and the anti-vibration device includes The rubber ring 61 connected with the inner wall of the pipe clamp hole 6 and the shockproof plate 62 connected with the rubber ring 61, one side of the rubber ring 61 is provided with threads, and is threaded with the inner wall of the pipe clamp hole 6, and the other side is provided with a groove, and A bump is provided in the groove, and the anti-vibration plate 62 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com