A Crank-slider Mechanism with Adjustable Stroke and Automatic Balance of Inertial Force

A crank-slider mechanism, crank mechanism technology, applied in mechanical equipment, transmission, belt/chain/gear and other directions, can solve the problems of waste of resources and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

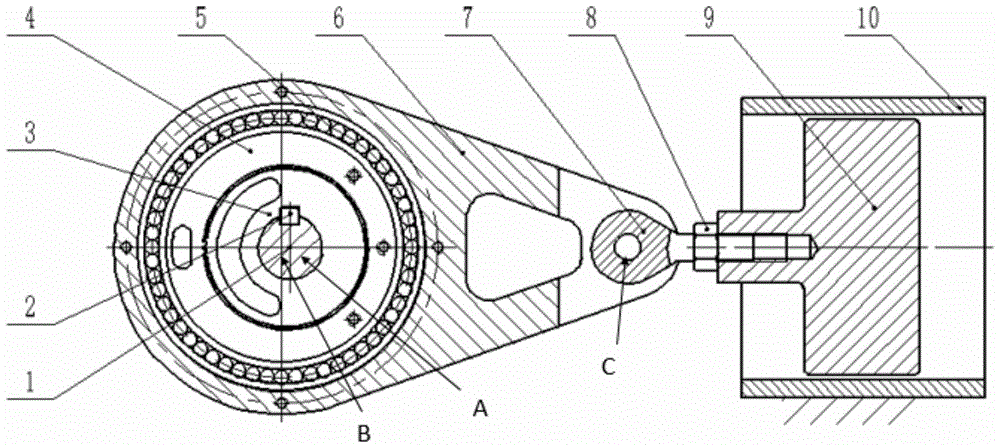

[0020] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0021] The design points of the present invention are as follows:

[0022] 1. Adjustable crank length

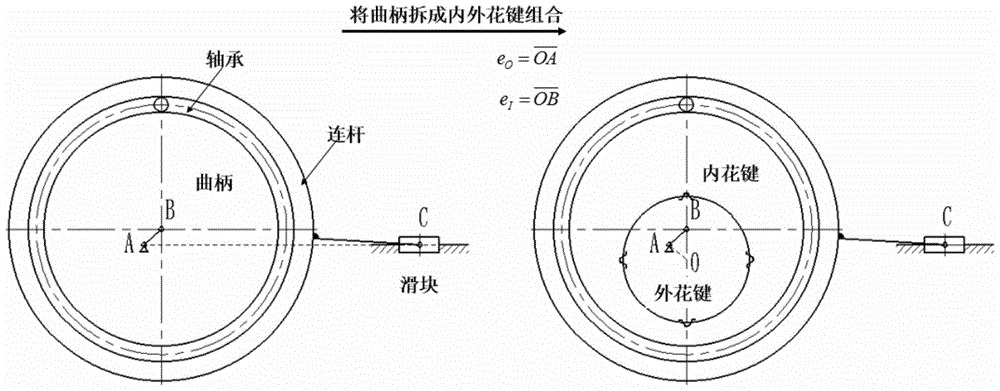

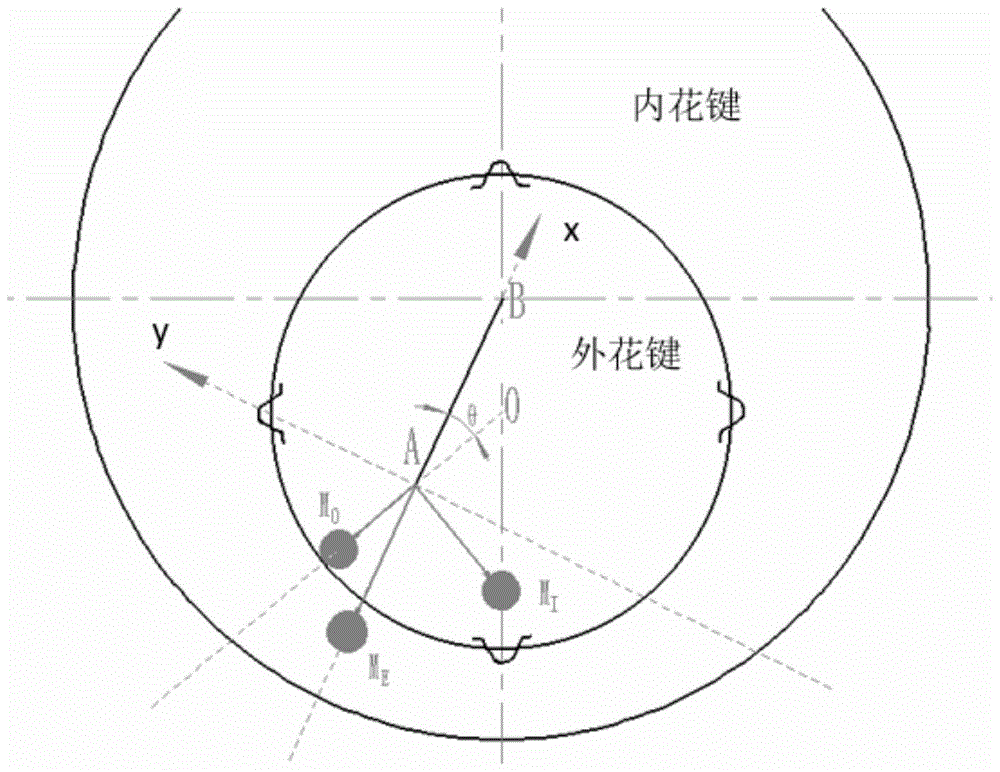

[0023] In order to obtain the crank-slider mechanism with adjustable slider stroke, the crank is disassembled into inner and outer spline combinations, such as figure 1 According to the design principle shown, each tooth of the spline rotates corresponds to a crank length, which realizes the adjustment of the crank length. Wherein O is the assembly center of the spline, A is the rotation center of the rotating pair composed of the crank and the bracket (also the rotating center of the motor shaft 1), and B is the rotating center of the rotating pair composed of the crank mechanism and the connecting rod.

[0024] The length of the crank can be expressed as:

[0025]

[0026] Then the stroke of the slider S=2l AB ∈[2|e O -e I |,2(e ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com