Device and method for carrying out in-situ observation on electric domain structure of ferroelectric material before and after electric field action

A ferroelectric material and electric field technology, applied in the field of ferroelectric materials, can solve the problems of unable to apply continuous pulse voltage, unable to observe the change of electric domain structure, low voltage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

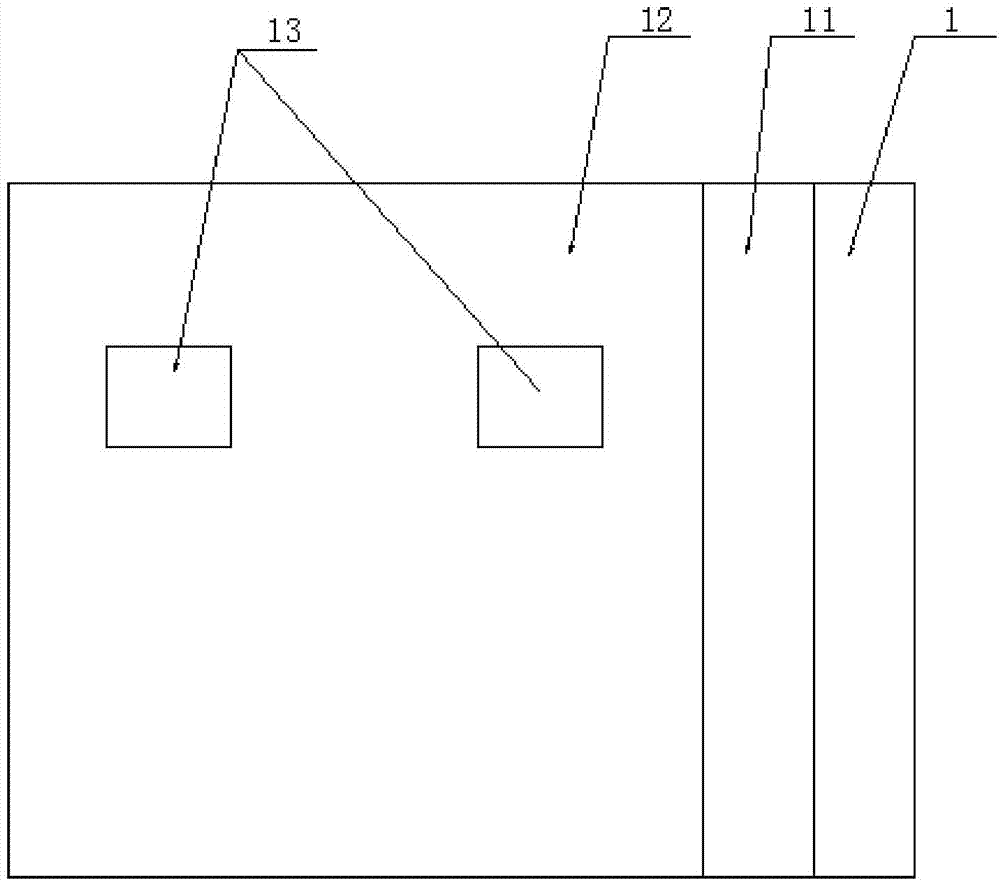

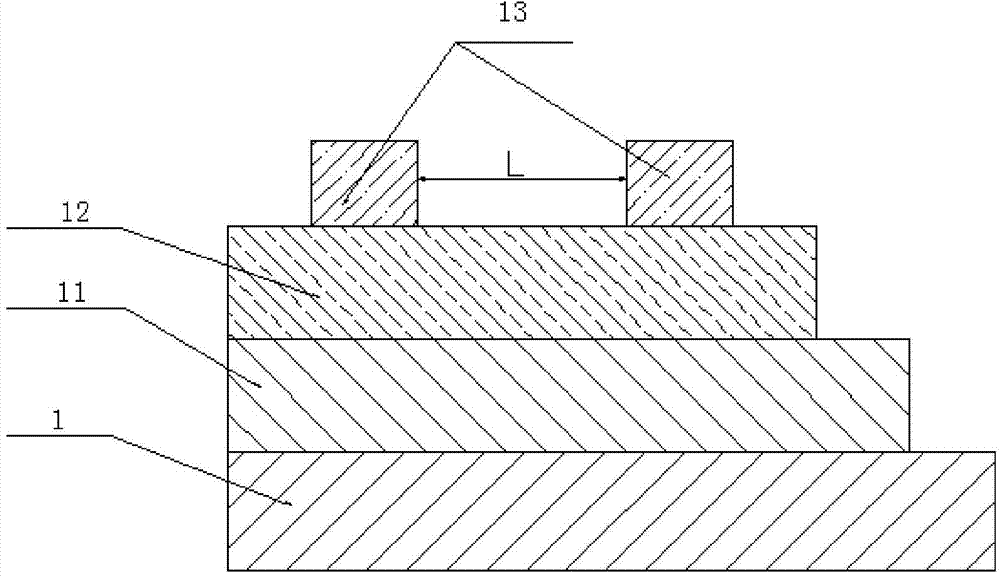

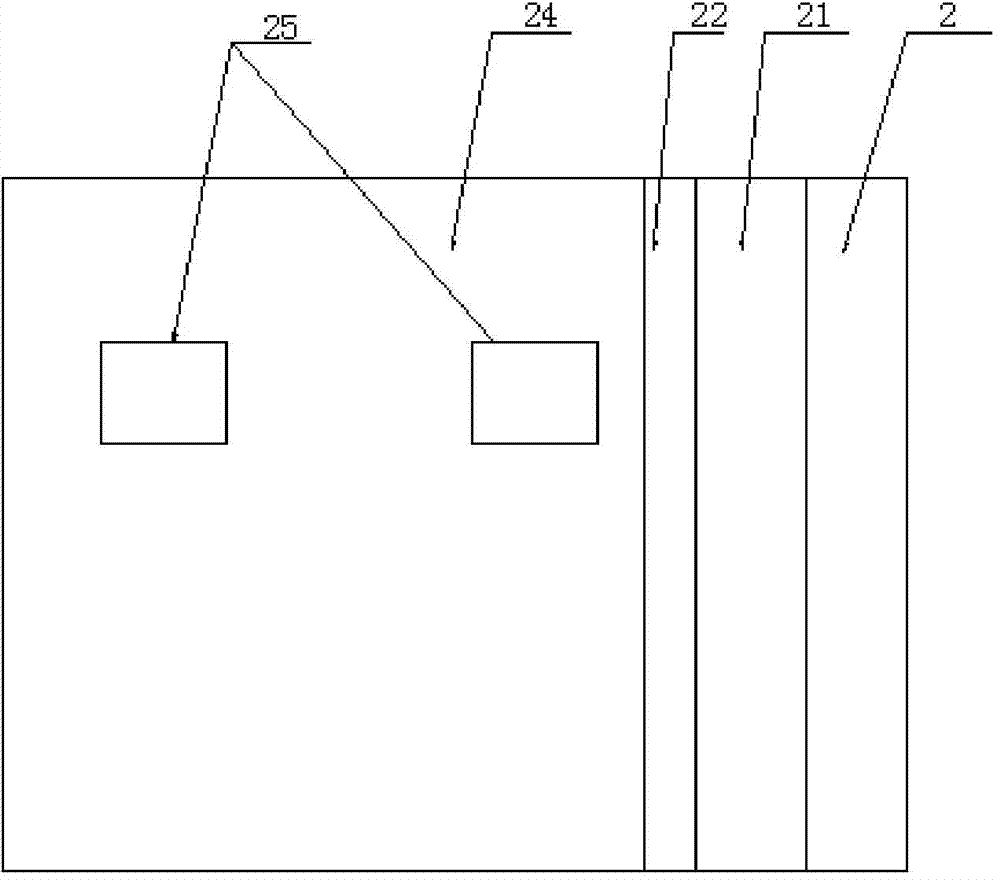

[0032] like figure 1 and figure 2 As shown, a device for in situ observation of the domain structure of ferroelectric materials before and after an electric field is applied, including:

[0033] a substrate 1;

[0034] The lower electrode 11 is grown on the substrate 1;

[0035] a ferroelectric thin film 12 grown on the lower electrode 11;

[0036] The two upper electrodes 13 are arranged on the ferroelectric thin film 12, the distance between the two upper electrodes 13 is L, and 1 μm≦L≦20 μm.

[0037] In this embodiment, the distance L between the two upper electrodes is 1 μm, and the upper electrodes 13 are arranged in a square shape with a side length of 100 μm.

[0038] A method for in-situ observation of the domain structure of a ferroelectric material before and after an electric field is applied, comprising the following steps:

[0039] A: Observe the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com