Feeding device for rubber stopper cleaning equipment

A technology for cleaning equipment and splicing devices, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high cost and troublesome operation, and achieve the effect of saving cost, facilitating maintenance and replacement, and ensuring fixed effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

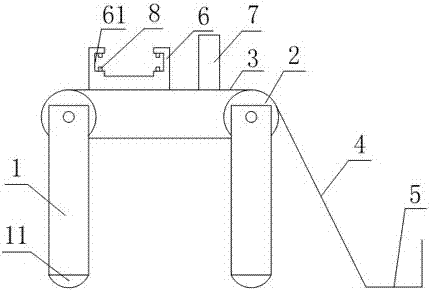

[0019] Such as figure 1 As shown, the material receiving device for rubber stopper cleaning equipment includes two symmetrically arranged fixed seats 1, the bottom of the fixed seat 1 is provided with a roller 11, the fixed seat 1 is provided with a pressure roller 2, and the pressure roller 2 is provided with a Cooperating belt 3, the output end of belt 3 is provided with dredging groove 4, and the end of dredging groove 4 is connected with collecting frame 5, and the bottom of dredging groove 4 and collecting frame 5 is 60 ° of angles, and the bottom of described belt 3 input The upper end surface is provided with a U-shaped fixing groove 6, and the bottom of the U-shaped fixing groove 6 is provided with a groove for placing a sterilization bag. The depth of the groove is 1 / 3 of the height of the U-shaped fixing groove 6, and the height of the U-shaped fixing groove 6 Both side walls are provided with draw-in slots 61, and the side walls of the draw-in slots 61 are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com