Intermittent printing equipment

A technology of printing equipment and printing rollers, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of high cost and inconvenient printing plate rollers, and the inability to replace printing plate rollers with different diameters, so as to enhance printing quality, Easy to adjust, install and disassemble the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

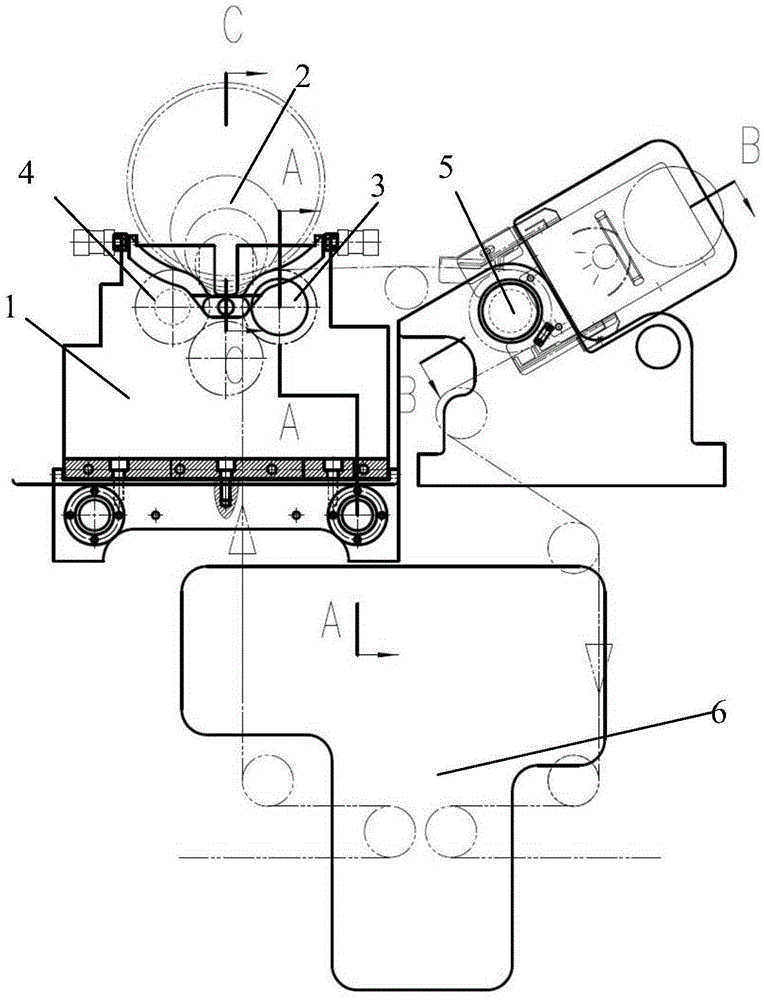

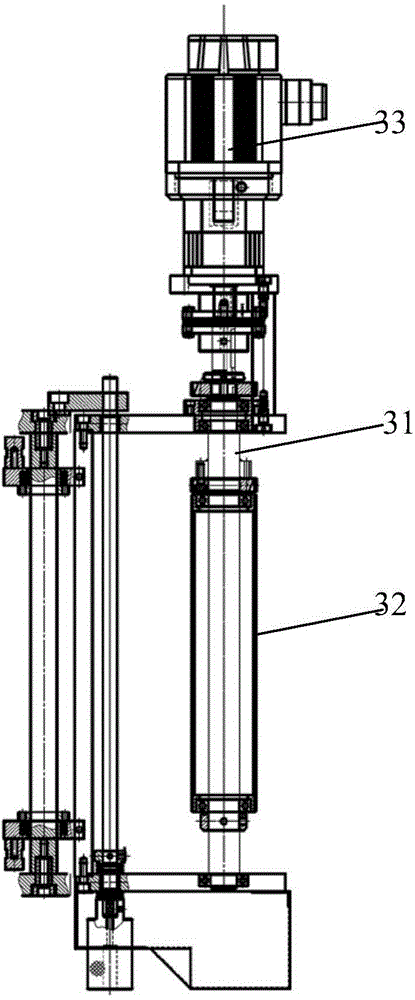

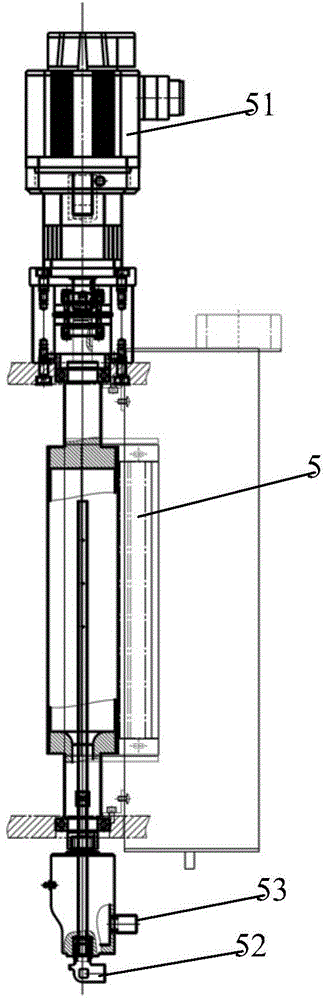

[0022] An intermittent printing device, comprising a support 1, a plate roller 2, and a printing roller 3, the printing roller 3 including a first mandrel 31, a printing roller cylinder 32, and a first motor 33 driving the first mandrel 31 , the first motor 33 is fixed on the support 1, the plate roll 2 includes a second mandrel 21 and a plate roll cylinder 22, the printing equipment also includes a bearing, and the support 1 is supported by a bearing The first mandrel 31 and the second mandrel 21, the first mandrel 31 supports the printing roller 32 through a bearing, and the second mandrel 21 supports the printing plate roller through a bearing drum 22 , and the first mandrel 31 drives the printing plate roller drum 22 . The mandrel of the printing roller 3 is used to drive the printing plate roller 22, which shifts the position of the driving force, and ensures that the printing plate roller 22 can be replaced with different diameters from the overall design.

[0023] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com