Building steel hoisting tool

A technology for hoisting tools and steel materials, which is applied in the directions of safety devices, transportation and packaging, and load suspension components, etc. It can solve the problems of safety accidents, easy-slip hoisting steel weight, and excessive size, and achieve the effect of preventing steel materials from slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

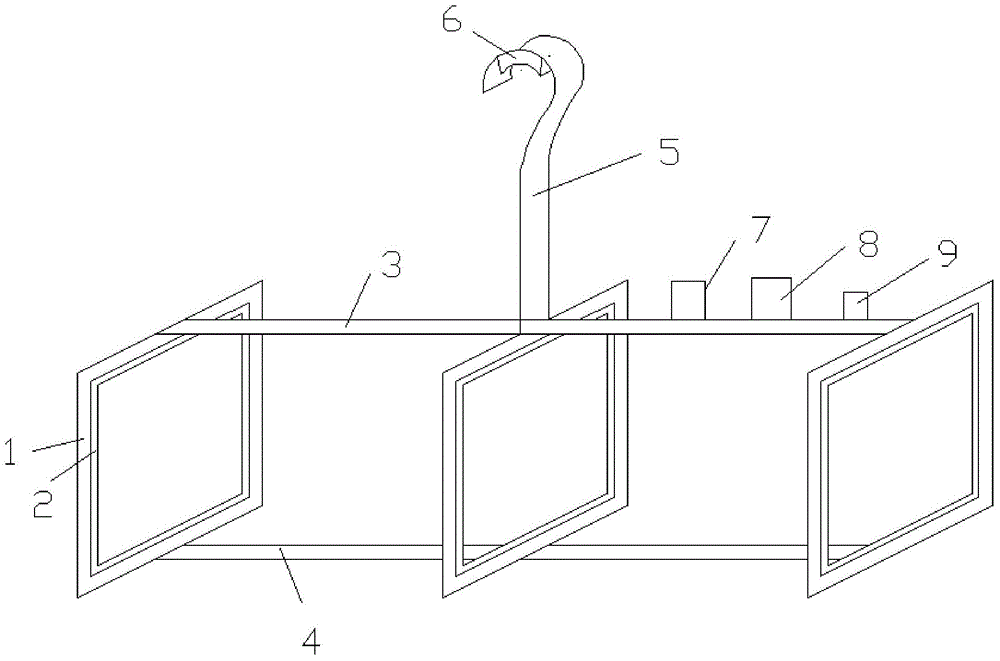

[0014] figure 1 The shown construction steel hoisting tool includes several openable hoops 1, and the inner surface of each hoop 1 is provided with an electromagnet 2, and the upper ends of adjacent hoops 1 are connected by a first connecting rod 3, adjacent hoops 1 The lower ends of the hoops 1 are connected by the second connecting rod 4, the first connecting rod 3 is connected with the suspension hook 5, the inner surface of the suspension hook 5 is connected with the pressure sensor 6, and the first connecting rod 3 is provided with a controller 7, an alarm The device 8, the storage battery 9, the pressure sensor 6 and the alarm device 8 are respectively connected to the controller 7, and the electromagnet 2, the pressure sensor 6, the controller 7 and the alarm device 8 are all connected to the storage battery 9 respectively.

[0015] The first connecting rod 3 and the second connecting rod 4 are welded to the hoop 1 respectively.

[0016] The number of said hoop is thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com