Installation method for one-side formwork of concrete wall

A technology for a concrete wall and an installation method, which is applied in the fields of formwork/template/work frame, construction material processing, and on-site preparation of construction components, can solve the problem of poor wall appearance quality, high labor input, and erection requirements. Long time and other problems, to achieve the effect of reducing the number of uses, easy to find, and easy to understand construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further illustrated below by specific examples.

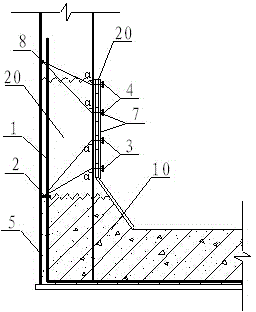

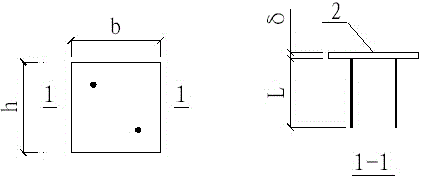

[0021] Such as figure 1 , figure 2 and image 3 As shown, a method for installing a concrete wall formwork on one side comprises the following steps;

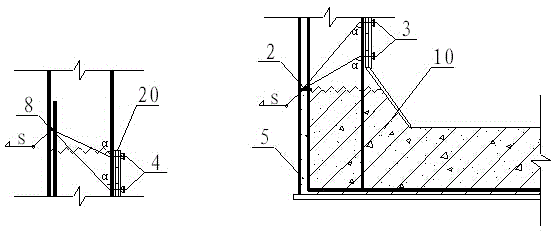

[0022] Step 1. When constructing the lower underground concrete structure 10, bury the iron piece 2 at the bottom of the vertical reinforcement 5 near the outside of the structure;

[0023] Step 2. Weld the bottom end of the lower pull screw rod 3 on the iron piece 2;

[0024] Step 3. Weld the bottom end of the upper pulling screw rod 4 to the H-shaped steel or steel sheet pile or the main reinforcement of the continuous wall in the foundation pit enclosure structure. The welding point 8 formed must be outside the scope of this pouring, that is, the welding point 8 It must be above the concrete pouring height of 20°C;

[0025] Step 4, install formwork component 7 from bottom to top;

[0026] Step 5. Connect and fix the formwork components i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap