Cooling passageway accumulated dust treatment device

A technology of processing device and cooling flow, applied in fixed tubular conduit assemblies, dispersed particle filtration, lighting and heating equipment, etc., can solve the problems of complicated operation and high cost, and achieve the effect of convenient operation and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

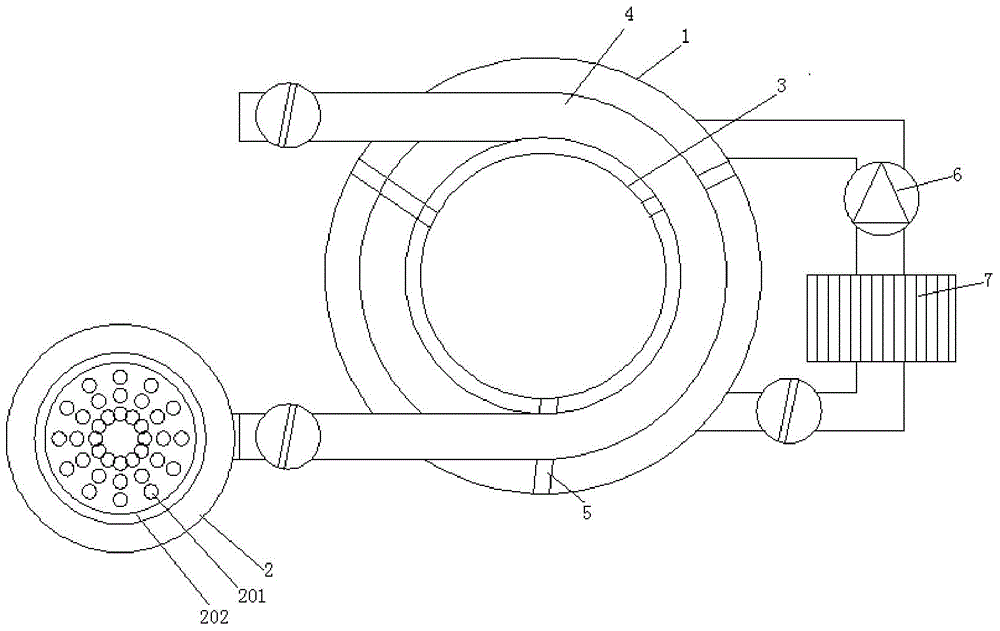

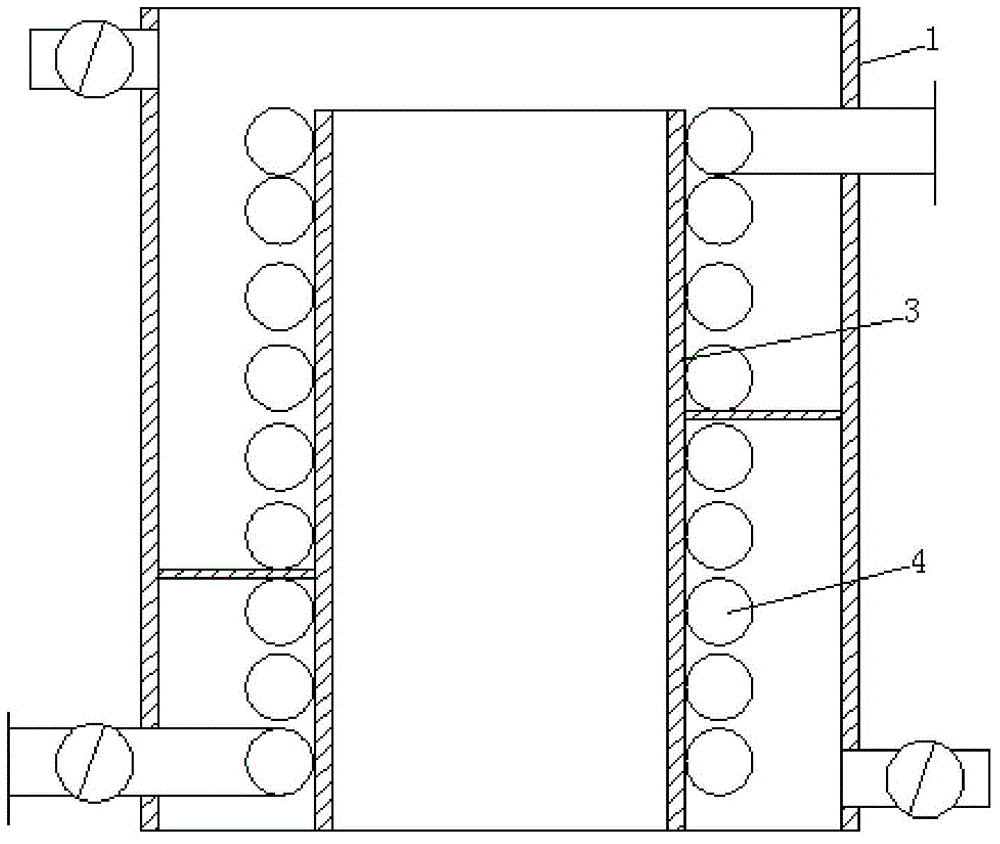

[0015] Referring to the accompanying drawings, a cooling channel dust treatment device includes a cooling box 1 and a dust collector 2, the air inlet of the dust collector 2 is connected to the cooling box 1, and the cooling box 1 is equipped with There is a fixed barrel 3, the upper end surface of the fixed barrel 3 is lower than the upper end surface of the cooling box 1, a cooling coil 4 is arranged between the cooling box 1 and the fixed barrel 3, and one end of the cooling coil 4 is connected to the cooling box The lower end of the body 1 is an air inlet, and one end is connected to the upper end of the cooling box 1 as an air outlet. A plurality of support rods 5 are arranged between the fixed barrel 3 and the cooling box 1 for supporting the cooling pipe 4 to fix. Cooling water is provided in the cooling box, and a cooling water circulation system is provided at the outer end of the cooling box. The cooling water circulation system includes a water pump 6, a water-coolin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap