Horizontal circulating type dust collector

A circulating flow, dust collector technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of inability to reduce noise, large pressure loss in the air flow path, long fluid flow path, etc., to optimize the dust removal effect. and efficiency, overcoming the effect of dust removal efficiency, overcoming the effect of long flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

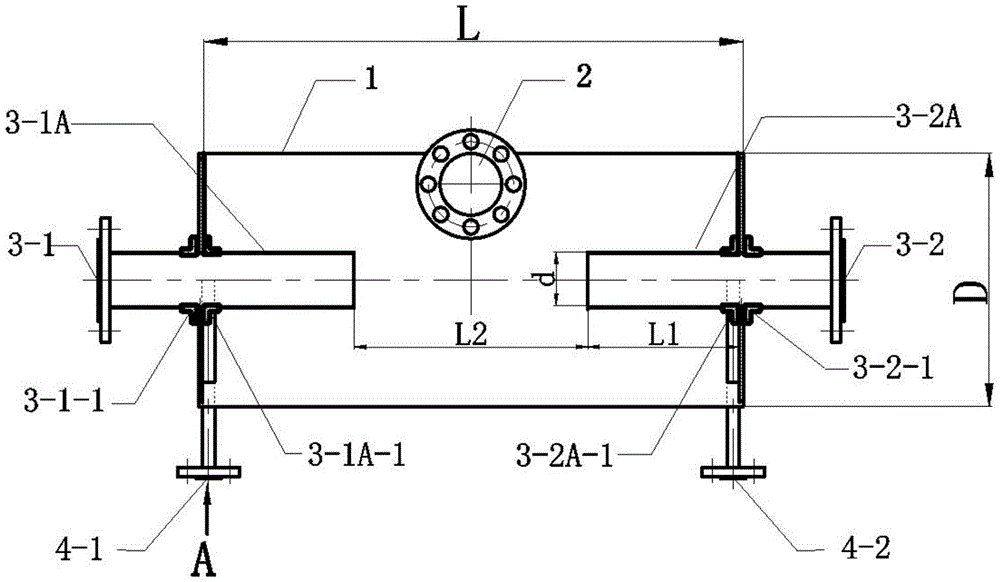

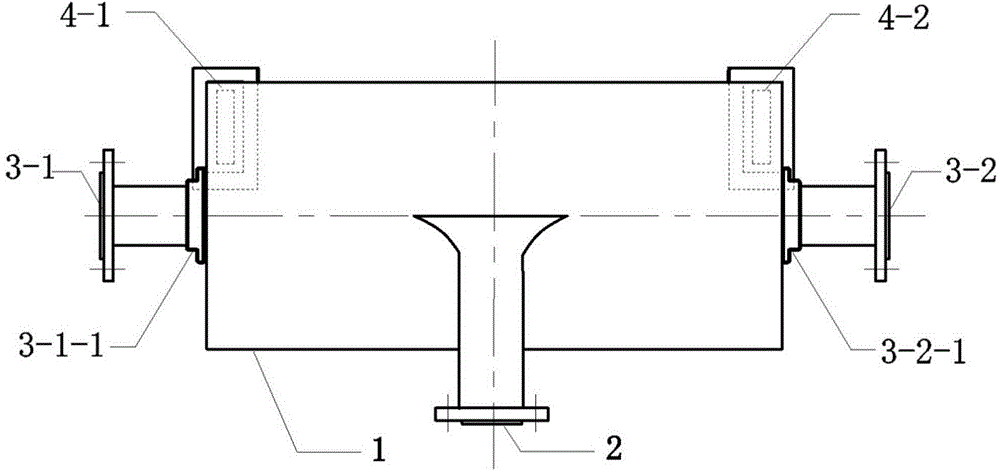

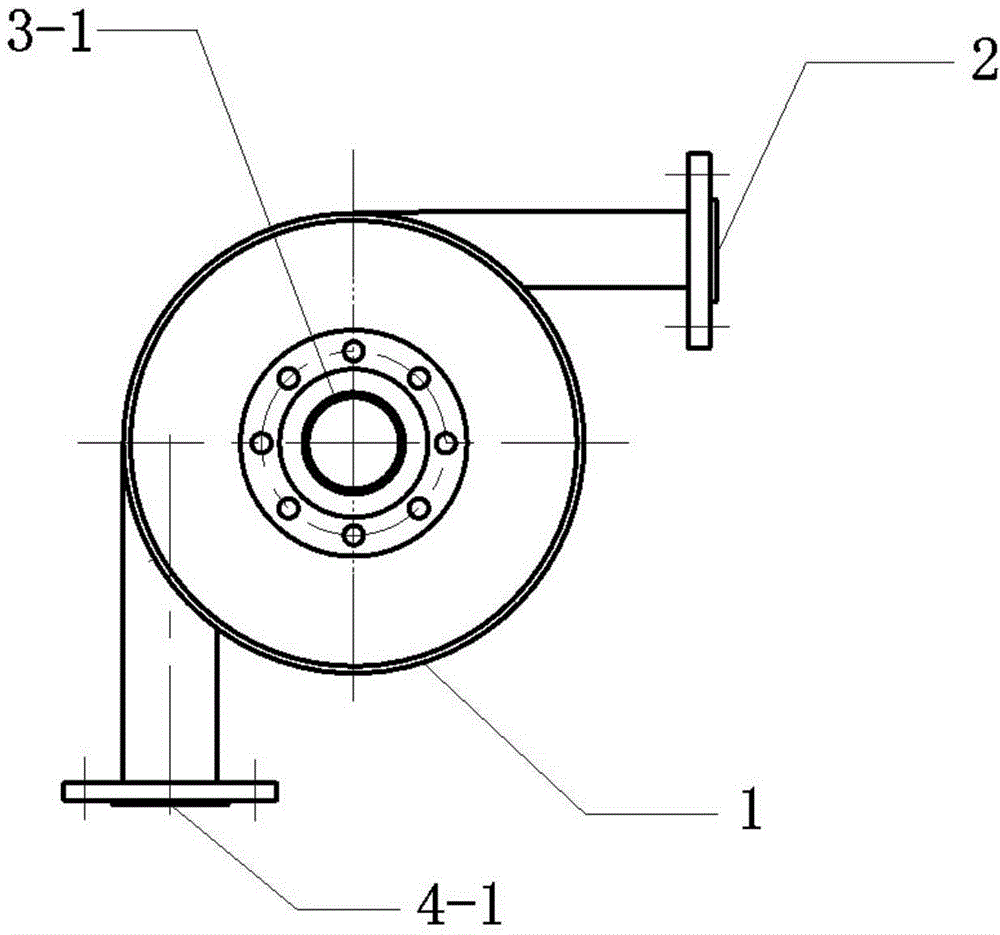

[0018] Describe the implementation process of the present invention in detail in conjunction with accompanying drawing, as figure 1 , figure 2 , image 3 , Figure 4 Shown, the present invention is by cylindrical body 1, air inlet pipe mouth 2, two clean gas exhaust pipe mouths 3-1, 3-2, two dust separation pipes 3-1A, 3-2A, two rectangular row The dust pipe mouth 4-1, 4-2 forms. The cylinder body 1 is arranged horizontally, and the two ends of the cylinder body 1 are sealed by sealing end caps; the air inlet pipe opening 2 is arranged at the upper part of the cylinder body 1 and connected tangentially with the cylinder body; two clean gas exhaust pipe openings 3 -1, 3-2, through the flange 3-1-1 and the flange 3-2-1, respectively, installed on the outside of the center of the sealing end cover at both ends of the cylinder 1; two dust separation pipes 3 -1A, 3-2A, through the flange 3-1A-1 and the flange 3-2A-1, are coaxial with the clean gas exhaust pipe ports 3-1, 3-2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com