Tundish covering agent for chromium-containing steel and application thereof

A tundish and covering agent technology, applied in the field of tundish covering agent for chromium-containing steel, can solve the problems of unsuitable chrome-containing steel continuous casting production, stay, and ineffective treatment of the performance of tundish covering agent, and achieve good spreading properties, preventing slag rolls, and improving viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

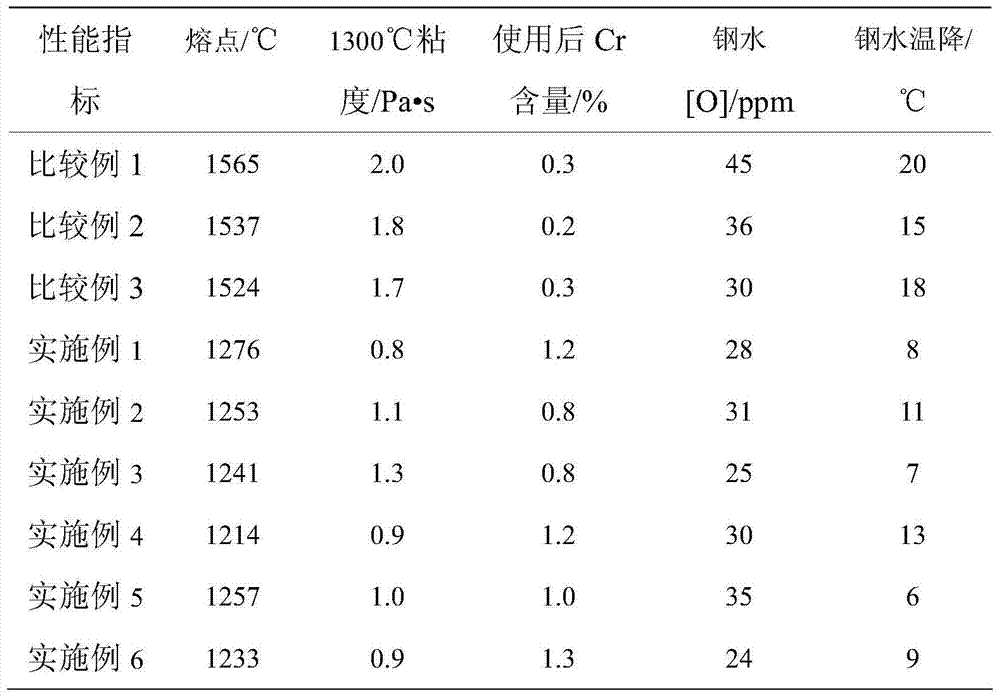

Embodiment 1

[0040] A tundish covering agent for chromium-containing steel, the composition mass percentage of which is CaO: 32%, SiO 2 : 10%, Al 2 o 3 : 33%, MgO: 10%, B 2 o 3 : 1%, (Na 2 O+Li 2 O): 14%. The alkalinity of the tundish covering agent is 3.2, and Na 2 O / Li 2 O (mass ratio) = 13:1, the main physical properties are shown in Table 1. The tundish covering agent designed in this embodiment is applied in the tundish of chromium-containing steel continuous casting, and the Cr content absorbed and melted in the tundish covering agent after casting is 1.2%, [O] in the tundish molten steel is less than 28ppm, and the molten steel temperature If the drop is less than 8°C, the corrosion of the ladle lining is not serious.

Embodiment 2

[0042] A tundish covering agent for chromium-containing steel, the composition mass percentage of which is CaO: 36%, SiO 2 : 8%, Al 2 o 3 : 33.8%, MgO: 7.5%, B 2 o 3 : 2.2%, (Na 2 O+Li 2 O): 12.5%. The alkalinity of the tundish covering agent is 4.5, and Na 2 O / Li 2 O (mass ratio) = 24:1, and the main physical properties are shown in Table 1. The tundish covering agent designed in this embodiment is applied in the tundish of chromium-containing steel continuous casting. After casting, the Cr content absorbed and melted in the tundish covering agent is 0.8%, [O] in the tundish molten steel is less than 31ppm, and the molten steel temperature If the drop is less than 11°C, the corrosion of the ladle lining is not serious.

Embodiment 3

[0044] A tundish covering agent for chromium-containing steel, the composition mass percentage of which is CaO: 42%, SiO 2 : 10%, Al 2 o 3 : 30%, MgO: 6%, B 2 o 3 : 2.0%, (Na 2 O+Li 2 O): 10%. The alkalinity of the tundish covering agent is 4.2, and Na 2 O / Li 2 O (mass ratio) = 9:1, and the main physical properties are shown in Table 1. The tundish covering agent designed in this embodiment is applied in the tundish of chromium-containing steel continuous casting. After casting, the Cr content absorbed and melted in the tundish covering agent is 0.8%, [O] in the tundish molten steel is less than 25ppm, and the molten steel temperature If the drop is less than 7°C, the corrosion of the ladle lining is not serious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com