Two-dimensional-laser real-time detection method of workpiece surface profile

A two-dimensional laser and real-time detection technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as the inability to stably extract straight line features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be described in further detail below in conjunction with the accompanying drawings.

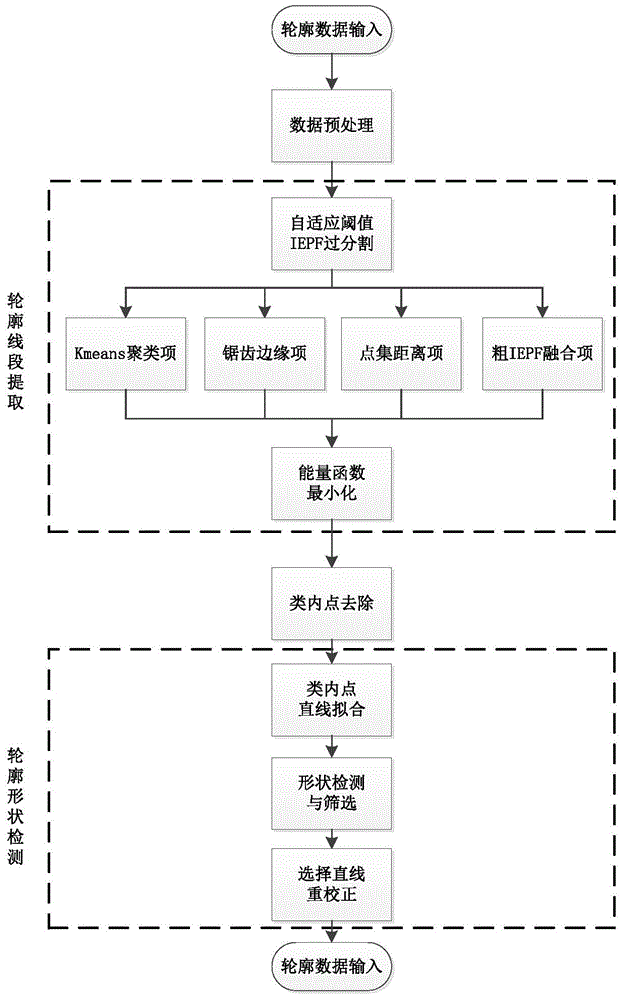

[0080] The invention provides a two-dimensional laser real-time detection method for the surface contour of a workpiece. figure 1 The overall flowchart of the method is divided into 4 major steps according to the flowchart, and the specific steps are as follows:

[0081] step one:

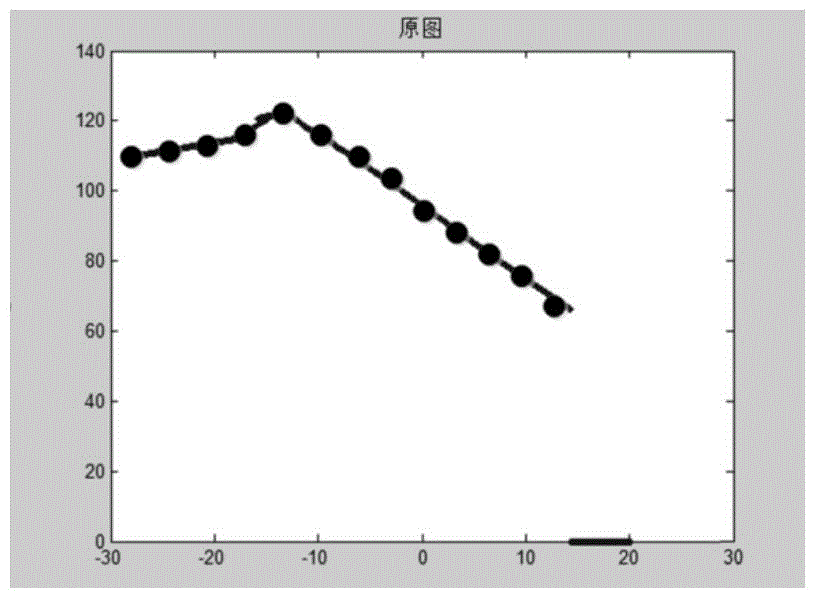

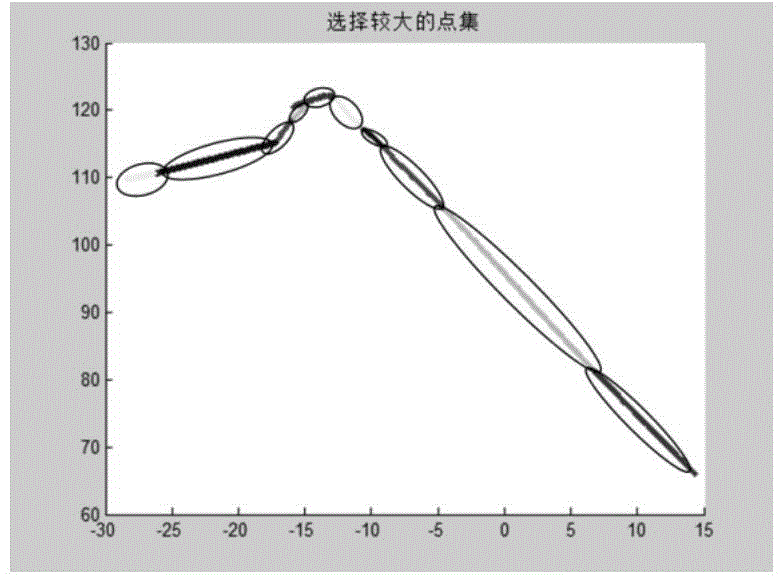

[0082] A frame of contour point data (such as figure 2 ), each point can be represented by the following symbols:

[0083] R={r 1 ,...,r l}.

[0084] Step two:

[0085] Preprocess the acquired contour point data, the preprocessing steps are:

[0086] (1) Zero value contour point removal

[0087] Due to the characteristics of the laser sensor, the distance of the environmental points beyond the range will be recorded as 0, so the contour points with zero values need to be removed.

[0088] (2) Repeated contour point removal

[0089] The laser sensor will obtain the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com