Adjustable gear-hob cutting force measurement device

A technology of gear hobbing cutting force and measuring device, which is applied to measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of inconvenient installation of gear workpieces, inconvenient cutting force data analysis, affecting the measurement accuracy of instruments, etc. Achieve the effect of short measurement preparation time, good rigidity and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

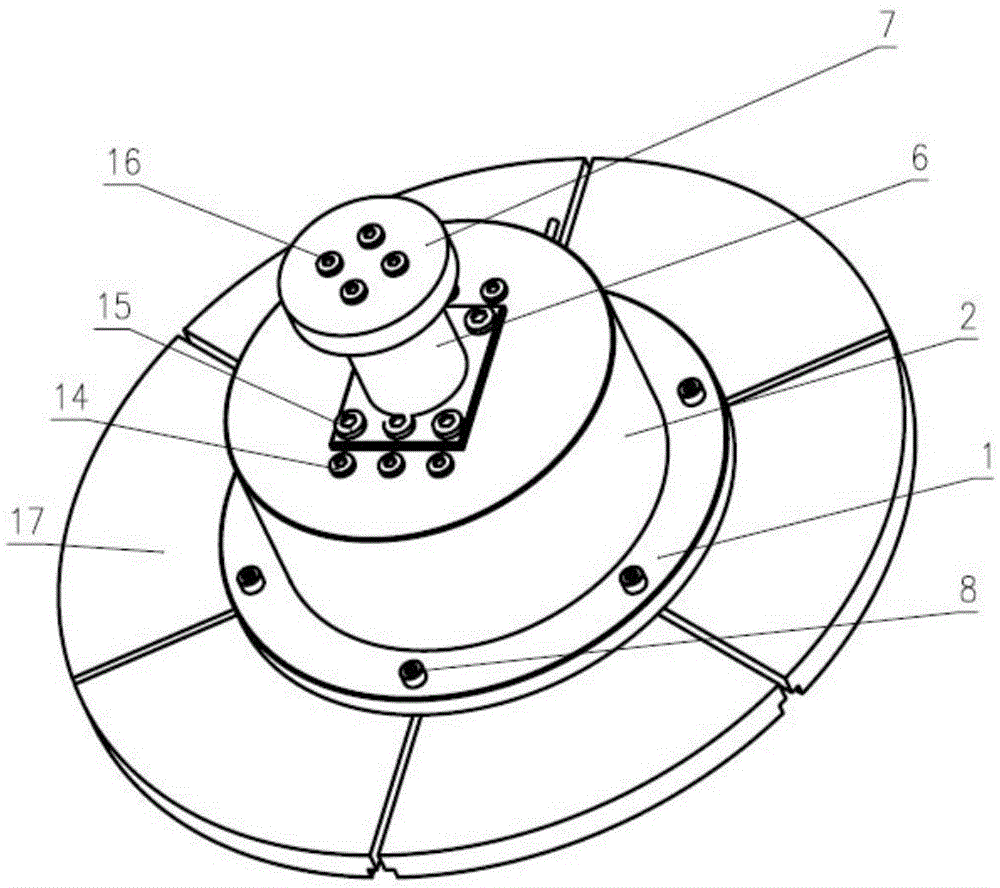

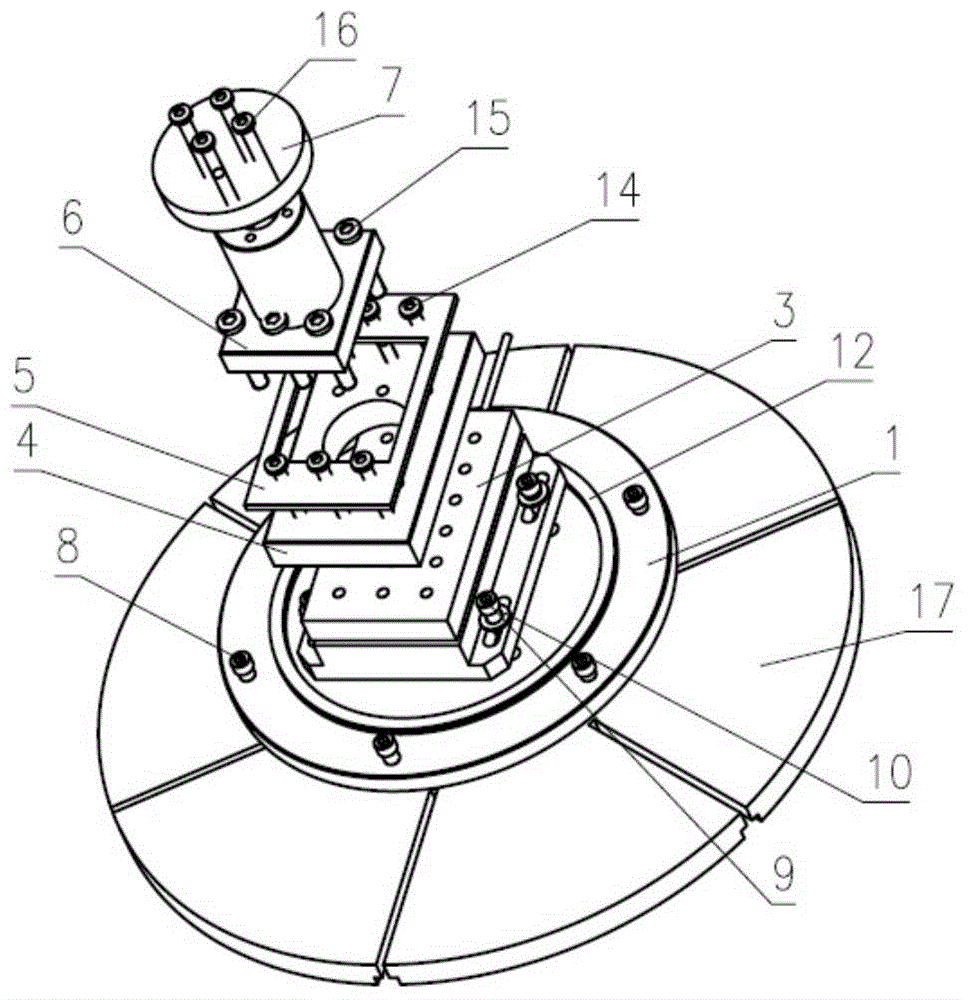

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

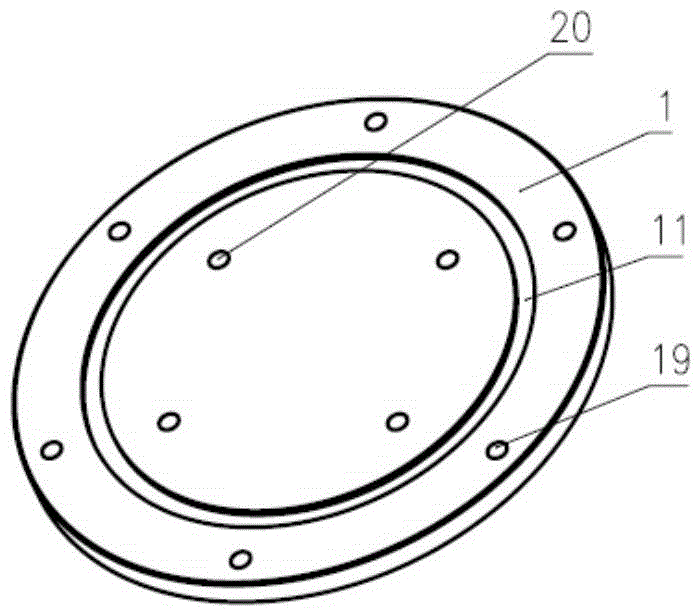

[0021] The schematic diagram of an adjustable hobbing force measuring device of the present invention is as follows Figure 1-Figure 8 As shown, it includes a bottom fixed plate 1, a cutting dynamometer 3, a top fixed plate 4, a sealing cover 2, a support mechanism and a square sealing ring 5, the bottom fixed plate 1 is circular, and the bottom fixed plate 1 is provided with There are circular grooves 11. The bottom of the cutting dynamometer 3 is fixedly connected to the bottom fixing plate 1 through a screw 9 and a washer 10 passing through a hole 20 . The top of the cutting dynamometer is provided with a top fixing plate 4 . Described support mechanism comprises positioning round platform 29, square platform 28 and support column 6, and described top fixed plate 4 is provided with the mounting hole 25 that matches with described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com