A remote-controlled wall automatic painting machine

A technology of remote control and painting machine, applied in the direction of construction, building structure, etc., can solve the problems of heavy equipment, unpainted walls, uneven coating, etc., to reduce the burden of workers and reduce harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

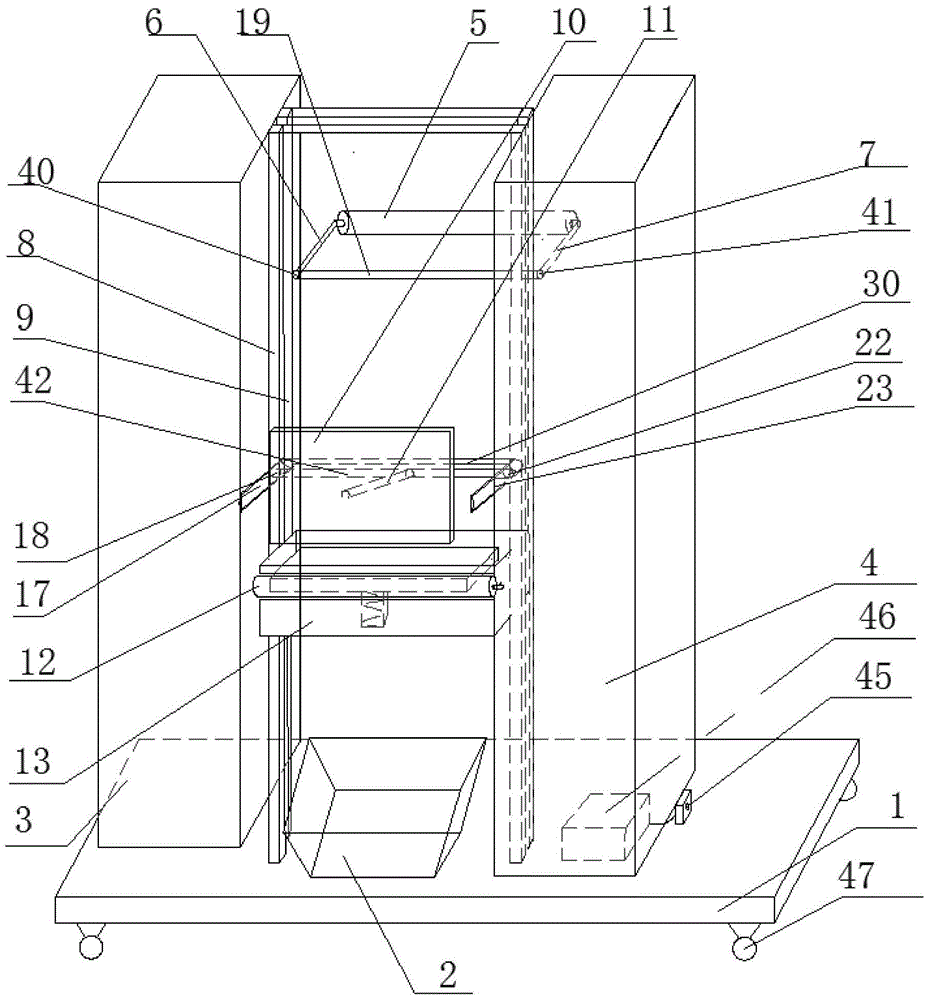

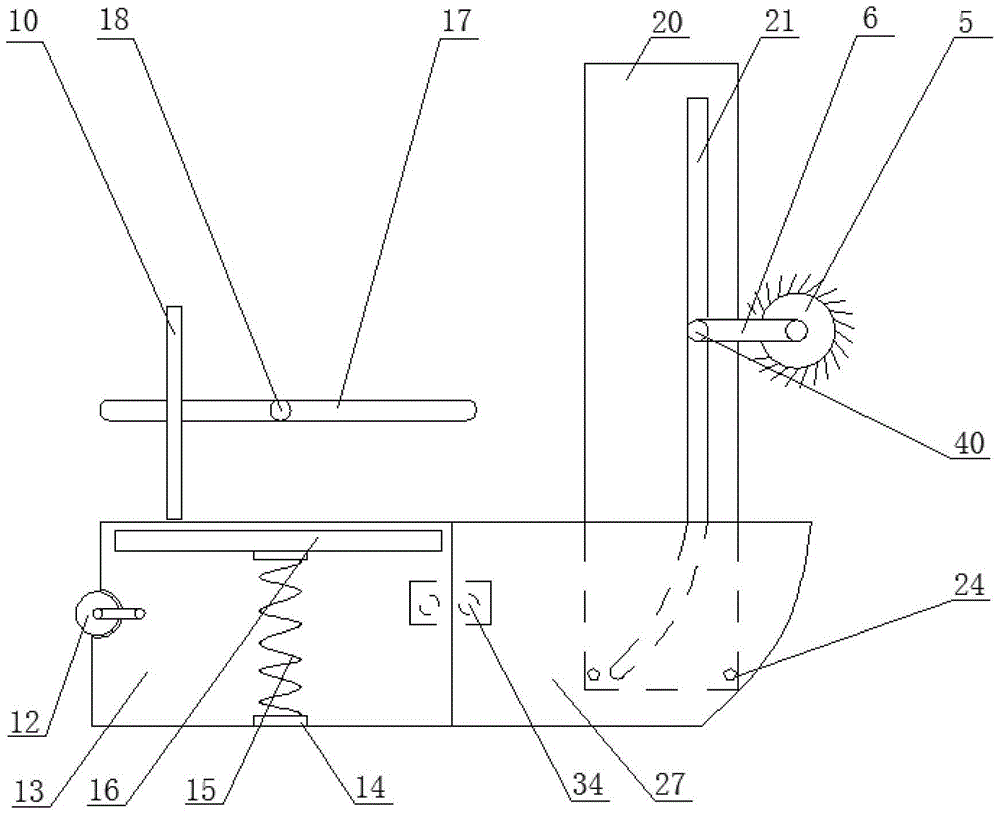

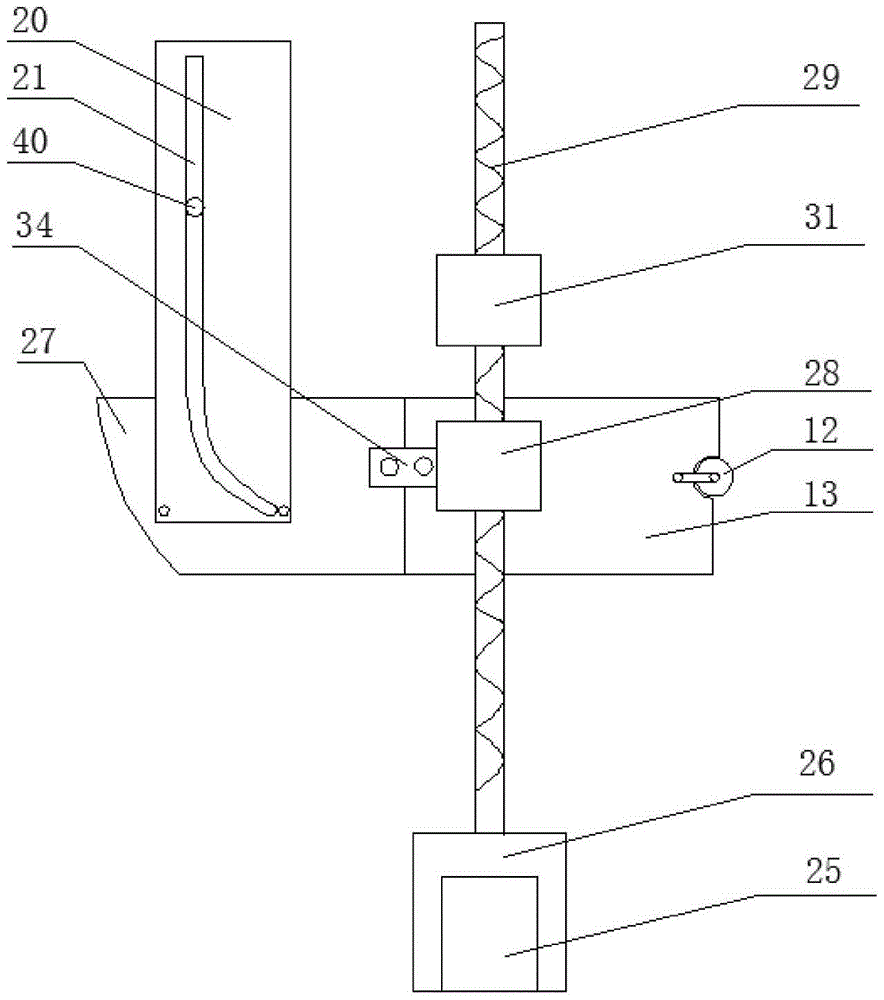

[0027] Such as Figure 1 to Figure 4 The shown remote-controlled automatic wall painting machine includes a mobile trolley 1, an electric wheel 47 is installed at the bottom of the mobile trolley 1, and a support frame is installed on the mobile trolley 1, and the support frame includes a front support frame 8 and the rear support frame 9, the front support frame 8 is sleeved with a raw material box, and the raw material box includes an old cement raw material box 13 and an old cement paint raw material box 27, and the old cement raw material box 13 and the old cement paint raw material box 27 pass through the right The fastening slider 32 and the left fastening slider 34 are connected together.

[0028] The left side of the old cement paint raw material box 27 is equipped with a left guide rail plate 20 through a threaded fastener 24, and the left guide rail plate 20 is provided with a left cement paint painting roller moving guide rail 21, and the left cement paint painting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com