Underseal opening type full-bore cementing sliding sleeve

An open-type, full-bore technology, applied in the direction of production fluid, sealing/package, wellbore/well components, etc., can solve the problems of high operating cost, easy pipe sticking, small diameter of ball seat, etc., and achieve convenient operation , Tool sealing performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

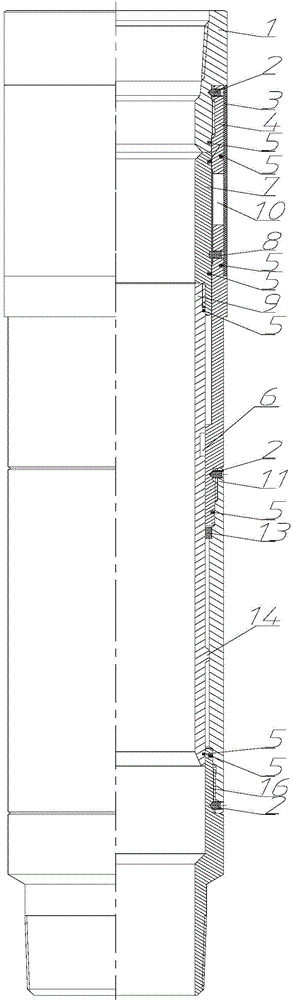

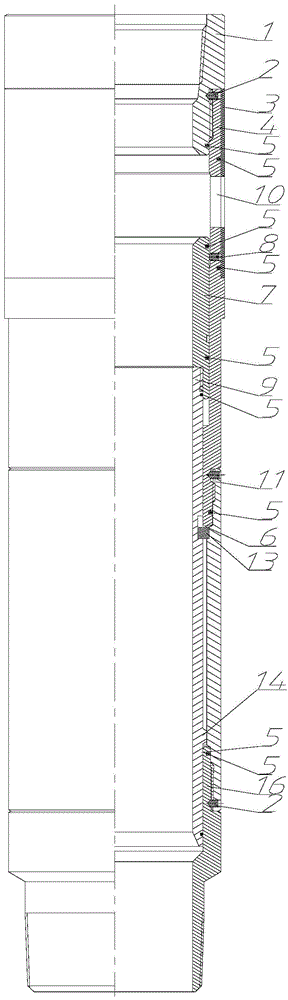

[0024] like figure 1 As shown, a bottom-sealed full-bore cementing sliding sleeve includes an upper joint 1, a lower joint 16, a central pipe 4, a rupture cylinder 3, a sliding sleeve 7, an inner cylinder 9 and an outer cylinder 11. The bottom seal is opened The upper and lower ends of the type full-bore cementing sliding sleeve are respectively connected to the casing through the upper 1 and the lower joint 16 to become a part of the casing; the upper end of the center pipe 4 is screwed to the upper joint 1, and the lower end is connected to the outer cylinder 11 connected; the bottom end of the outer cylinder 11 and the lower joint 16 are connected by threads; the upper joint 1 and the central pipe 4, the lower joint 16 and the outer cylinder 11 are all fastened by the set screw 2; the central pipe 4 is connected with the sliding sleeve by the shear nail 8 7 connection, the bottom end of the sliding sleeve 7 is provided with a stepped surface; the upper end of the inner cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com