X-ray flaw detection device for alloy round cutter

A flaw detection and X-ray technology, which is applied in the field of X-ray flaw detection and detection devices for alloy round cutters, can solve problems such as hidden dangers in the processing process of enterprises, cutting tools entering the market, and poor performance, so as to ensure processing quality, processing safety, and detection High work efficiency, light operation, labor-saving and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

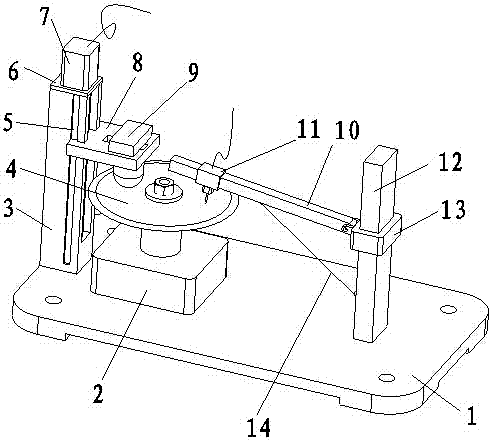

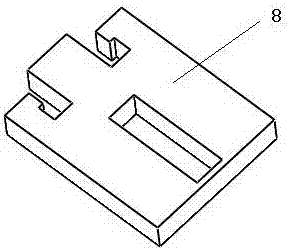

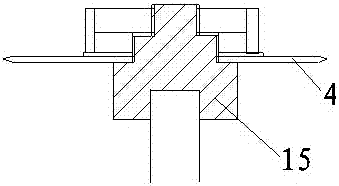

[0014] Such as figure 1 and image 3 As shown, a kind of alloy circular cutter X-ray flaw detection detection device of the present invention, described detection device comprises base 1, motor 2, pressure column 3, cemented carbide blade 4, high-frequency impact head 11; Described base 1 A motor 2 is vertically installed on the top, and a detection seat 15 is installed on the shaft of the motor 2. The center of the detection seat 15 is provided with a fixed shaft, and the upper end of the fixed shaft is provided with a threaded section of a large boss and a threaded section of a small boss. The outer diameter of the nut installed on the large boss thread section and the small boss thread section of the fixed shaft of the detection seat 15 is the same, and the outer diameter of the nut is installed with a thread, and a locknut is provided on the installation thread. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com