Switch unit structure

A switching unit and switching device technology, applied in power transmission and AC networks, etc., can solve the problems of cumbersome electrical connection of switching devices, uneven conductive contact, inconvenient disassembly, assembly and maintenance, etc., achieves compact and beautiful mechanical installation structure, and reduces insulation coordination. Safe and reliable effect of size, insulation and coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

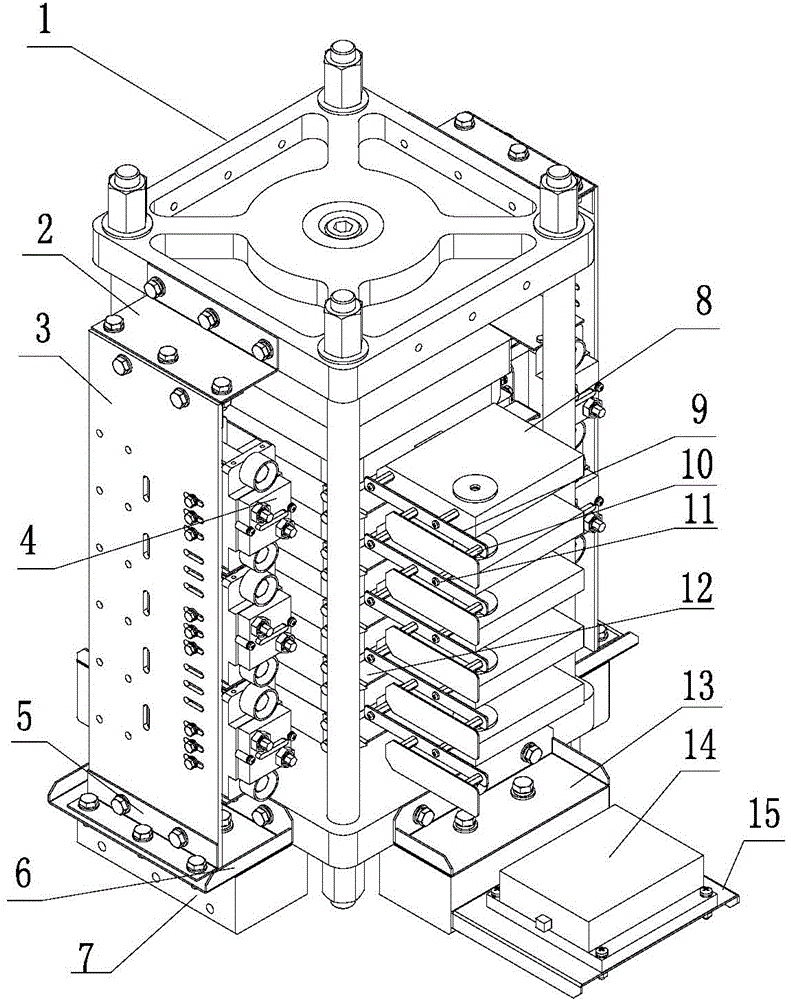

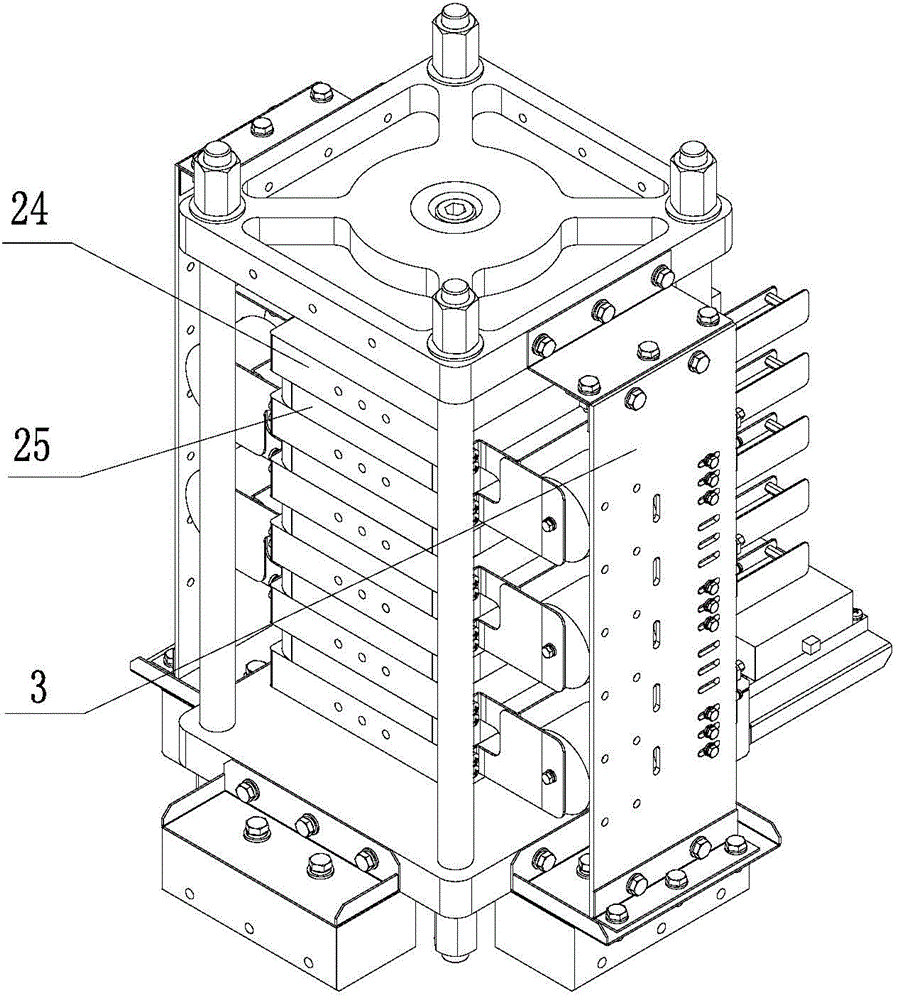

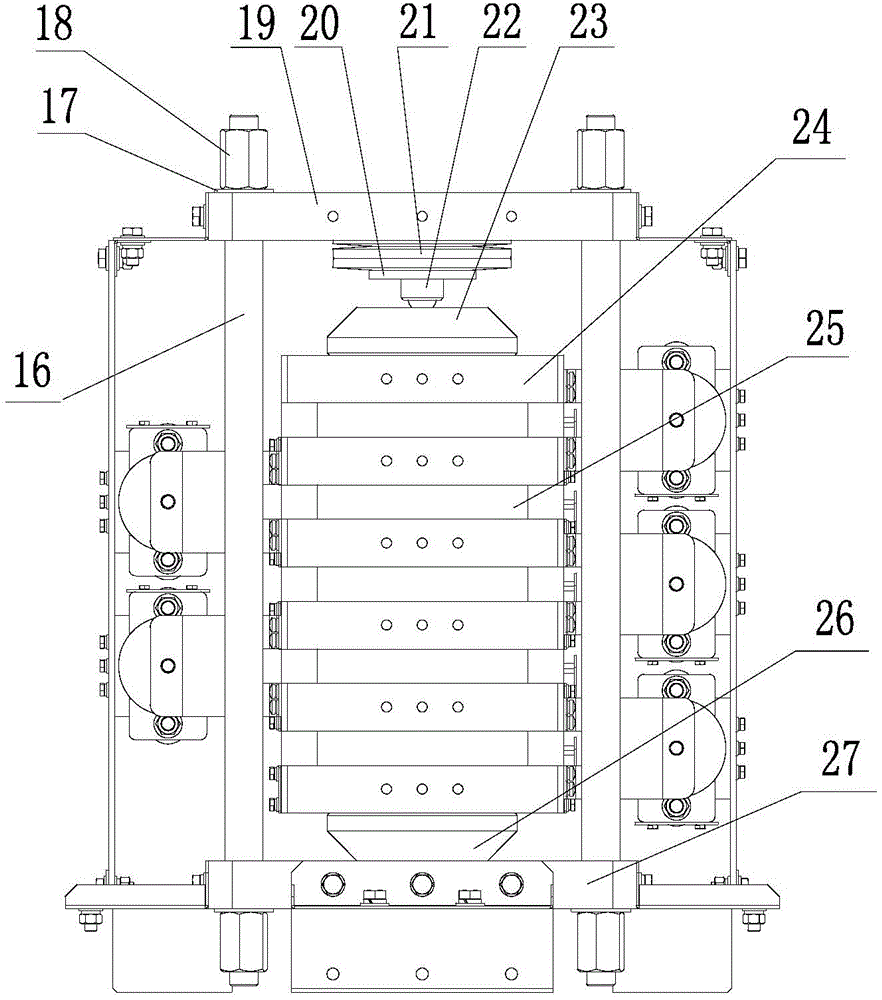

[0027] See Figure 1-Figure 7 , a switch unit structure, including a press-fit switch device structure 1, a voltage equalizing device structure 4, a device driver 8, a drive clamp 9 and a drive power supply 14, the overall frame is composed of a resin support plate 16, and end plates I located on the upper and lower sides 19 and end plate II 27, on both sides of the overall frame there are pressure equalizing device support plates 3, the upper part of the pressure equalizing device structural support plate 3 is fixed with the end plate I19 through the upper support 2, and the lower part of the pressure equalizing device structural support plate 3 The support seat I6 and the support plate corner piece 5 are fixed to the end plate II 27, the device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com