Steam sterilizer with sealed structure

A technology of steam sterilization and sealing structure, applied in heating and other directions, can solve problems such as poor sealing, and achieve the effects of increasing sealing, avoiding slipping, and avoiding tight sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

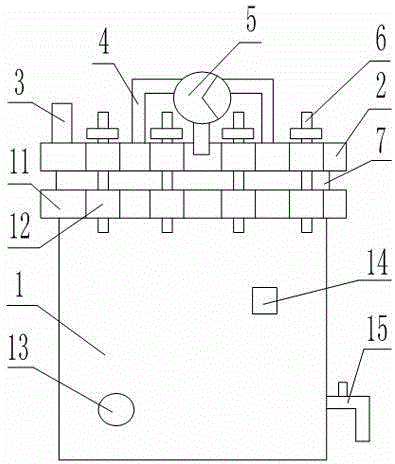

[0020] Such as figure 1 , figure 2 As shown, the steam sterilizer with a sealed structure includes a cylinder body 1, a cylinder cover 2 matched with the cylinder body 1, a switch button 14 and an insertion hole 13 are arranged on the cylinder body 1, and the lower end side wall of the cylinder body 1 is provided with There is a water outlet pipe 15, and the cylinder cover 2 is provided with an air nozzle 3, a pressure gauge 5, and a handle bar 4. The outer wall of the cylinder body 1 and the cylinder cover 2 is provided with an annular flange 11, and the annular flange 11 is integrated with the cylinder body 1 structure, the outer wall of the annular flange 11 and the cylinder cover 2 is provided with 8 groups of fixed blocks 12 that cooperate with each other, and the inside of the fixed blocks 12 is provided with a threaded through hole, and the lead screw 6 provided with a nut is passed through the threaded through hole, The upper end of the annular flange 11 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com