Deodorant sheet and its manufacturing method

A manufacturing method and sheet technology, applied in deodorization, disinfection, etc., can solve the problems of loss of deodorization function, difficulty in achieving stable and consistent deodorization effect of deodorization sheets, difficulty in fiber bonding, etc., to achieve good deodorization effect , Guarantee the effect of deodorization and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

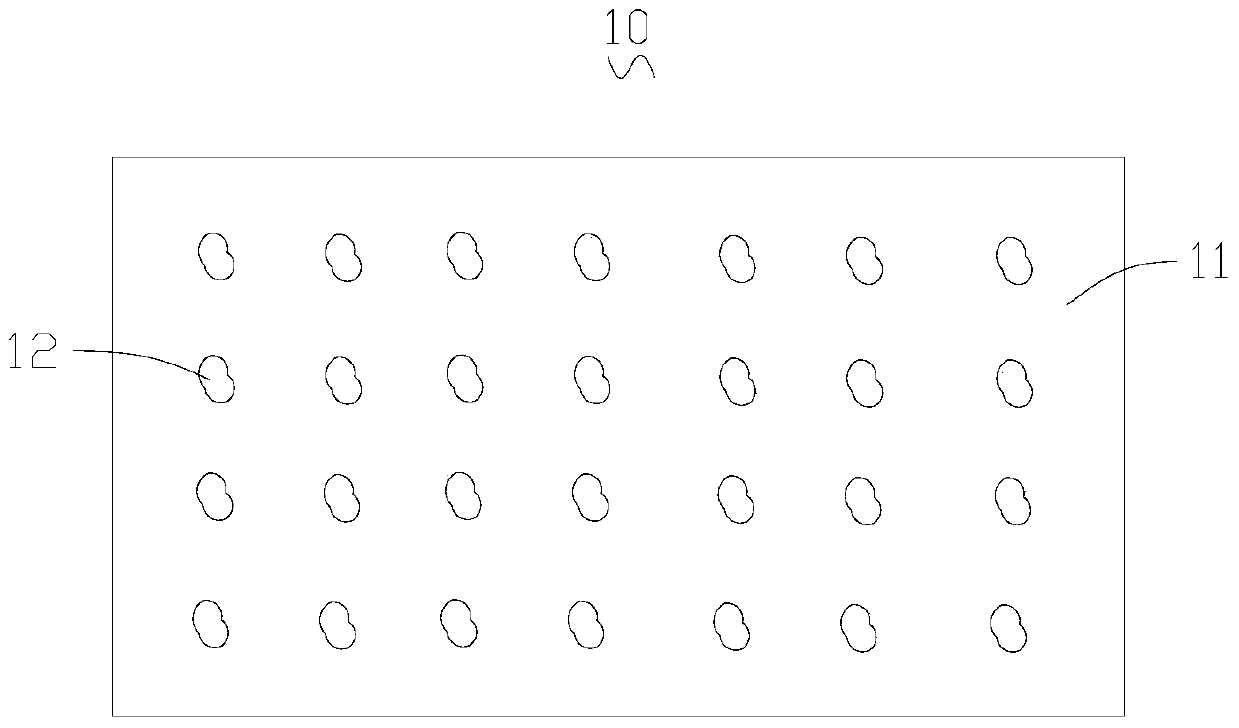

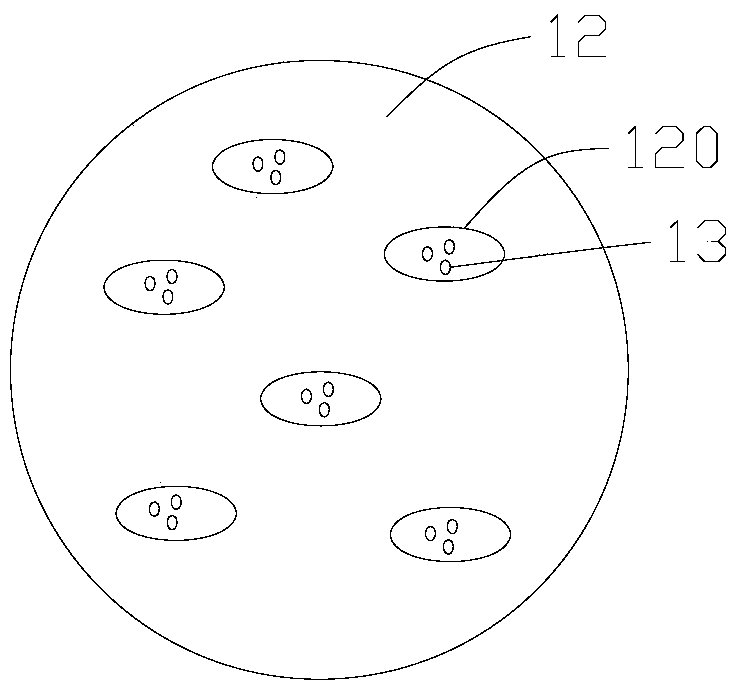

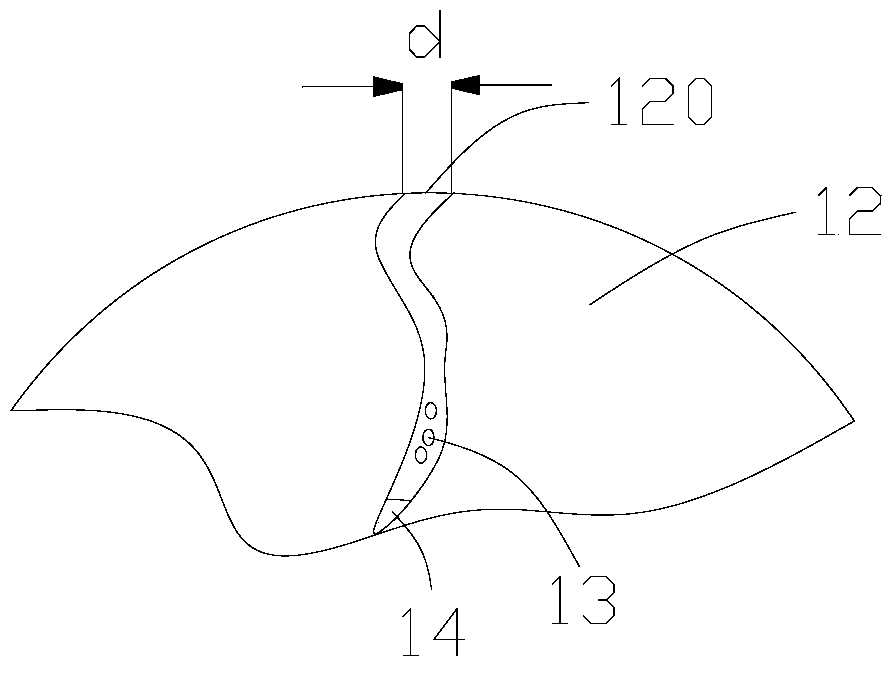

[0025] see Figure 1 to Figure 4 , figure 1 It is a structural schematic diagram of an embodiment of the deodorant sheet of the present invention, figure 2 yes figure 1 The schematic diagram of the structure of the oil-absorbing material layer and the deodorant substance of the shown deodorant sheet, image 3 yes figure 2 Schematic diagram of the structure of the shown oil-absorbing material layer, deodorizing substance and odor substance, Figure 4 yes image 3 Schematic diagram of the structures of deodorant substances and odor substances shown.

[0026] The deodorant sheet 10 of the embodiment of the present invention includes but not limited to a skeleton structure 11 , an oil-absorbing material layer 12 , a deodorant substance 13 and an odor substance 14 .

[0027] It should be noted that the deodorant sheet 10 of this embodiment can be household paper, decorative paper, writing paper, packaging paper, cardboard, etc., and its basis weight can generally be 10 g / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com