Speed measurement device for crusher rotor

A speed measuring device and crusher technology, which is applied to devices using optical methods, grain processing, etc., can solve the problems of large vibration amplitude, affecting the service life of the speed measuring device, and large ash, so as to achieve the effect of guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

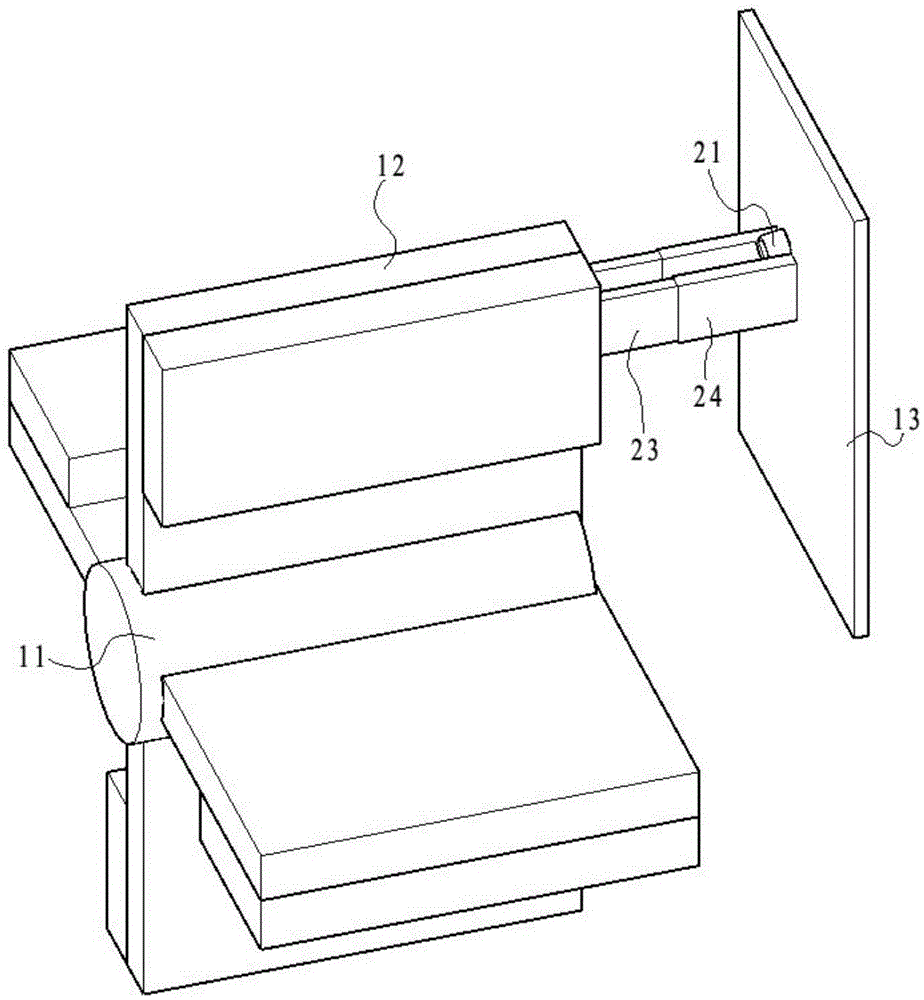

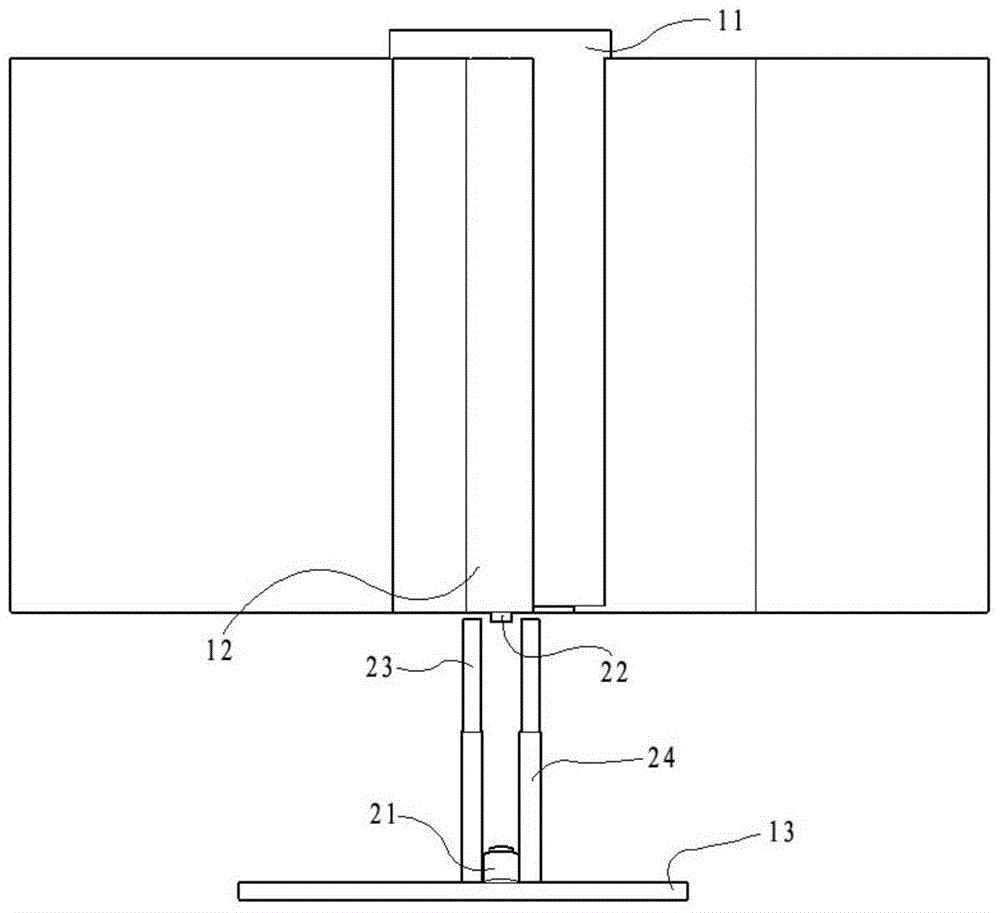

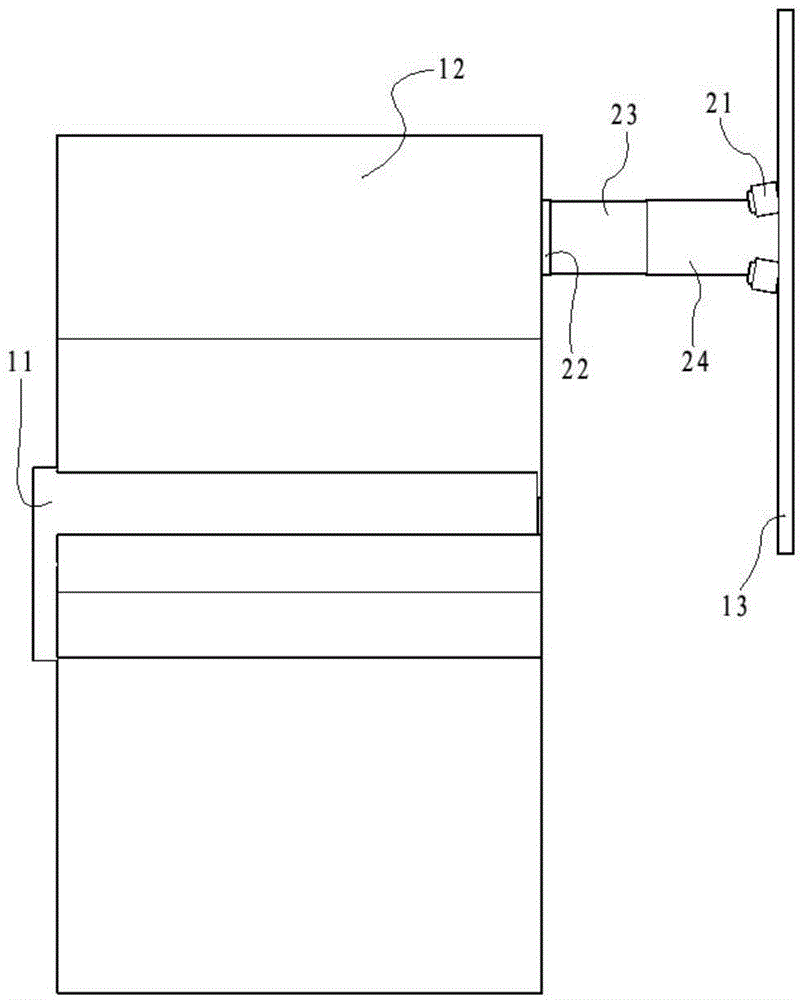

[0017] like Figure 1 to Figure 3 The crusher rotor speed measuring device shown includes a rotor shaft 11, a rotor 12, a housing 13, an infrared device 21, and a mirror 22; the rotor 12 is fixed on the rotor shaft 11, and the side of the rotor 12 is fixed with a reflective A mirror 22, an infrared device 21 is fixed on the side of the housing 13 corresponding to the rotor axis 11 and the rotor 12; the infrared device 21 is an infrared emitting device and an infrared receiving device, and both the infrared emitting device and the infrared receiving device are facing the reflection mirror 22, and the infrared light emitted by the infrared emitting device is reflected by the reflective mirror 22 and can be received by the infrared receiving device.

[0018] Thus, the rotational speed of the rotor 12 can be easily calculated through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com