Bicycle hub ratchet wheel structure

A technology for bicycles and hubs, applied in the direction of hubs, vehicle parts, one-way clutches, etc., can solve the problems of increasing the size and weight of the hubs, affecting the structural strength of the ratchet ring, and achieve the increase of the axial size and transmission. Power, the effect of increasing reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

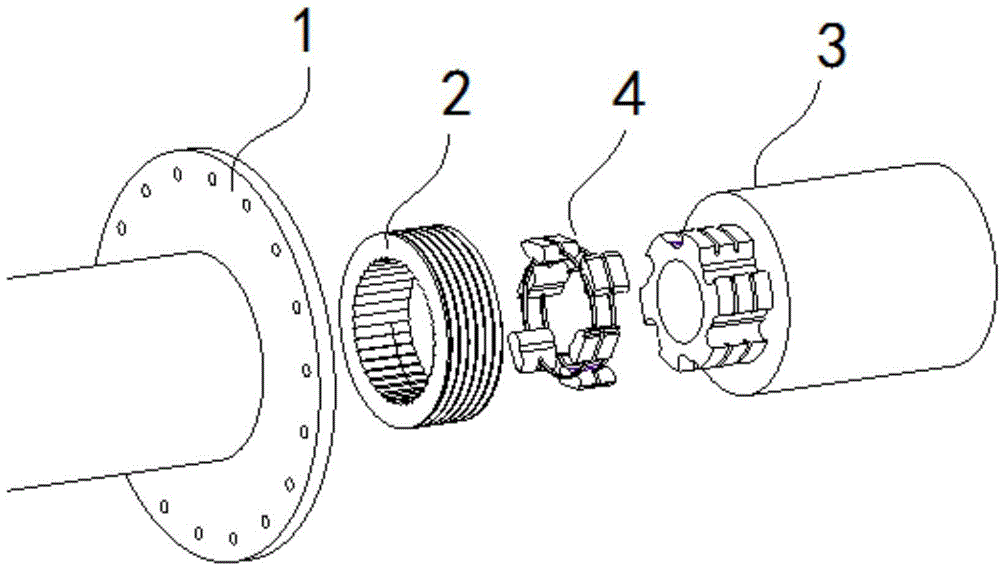

[0028] like figure 1 As shown, a bicycle hub ratchet structure of the present invention includes: a hub 1 , a ratchet ring 2 , a sleeve 3 , and a ratchet pawl group 4 .

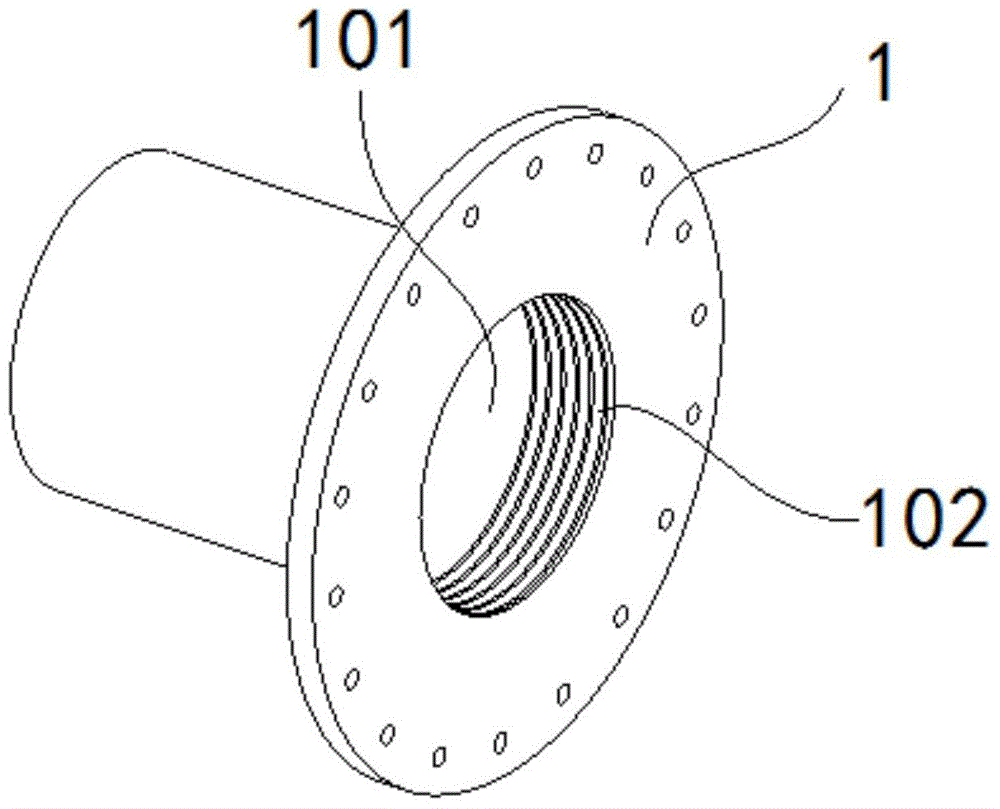

[0029] like figure 2 As shown, the hub 1 is provided with a first through hole 101 therein. An inner thread 102 is provided on the inner wall of the first through hole 101 .

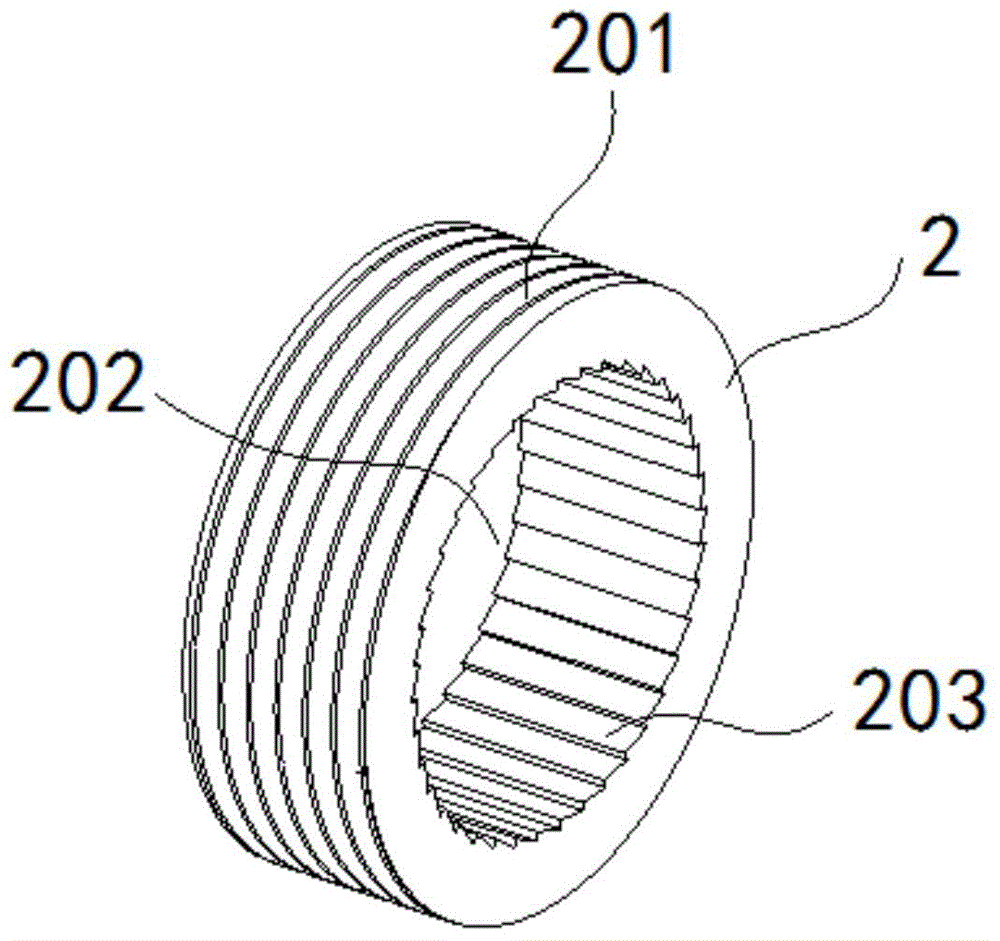

[0030] like image 3 As shown, the ratchet ring 2 is connected to the hub 1 , the ratchet ring 2 is provided with a second through hole 202 , and the second through hole 202 is provided with a plurality of ratchet teeth 203 . The outer wall of the ratchet ring 2 is provided with an external thread 201, the external thread 201 and the internal thread 102 are correspondingly arranged, and the hub 1 and the ratchet ring 2 pass through the internal thread 102 and the external thread 102. Thread 201 connection.

[0031] like Figure 4 As shown, the first end of the sleeve 3 is provided with a boss 301 , and the boss 301 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com