Trimanganese tetroxide/carbon composite with rodlike core-shell structure as well as preparation method and application of trimanganese tetroxide/carbon composite

A technology of trimanganese tetraoxide and carbon composite materials, which is applied in the direction of structural parts, electrochemical generators, active material electrodes, etc., can solve the problems of limited application of trimanganese tetraoxide, poor cycle stability, and microstructure collapse, and achieve Effects of shortening migration distance, improving stability, and enhancing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

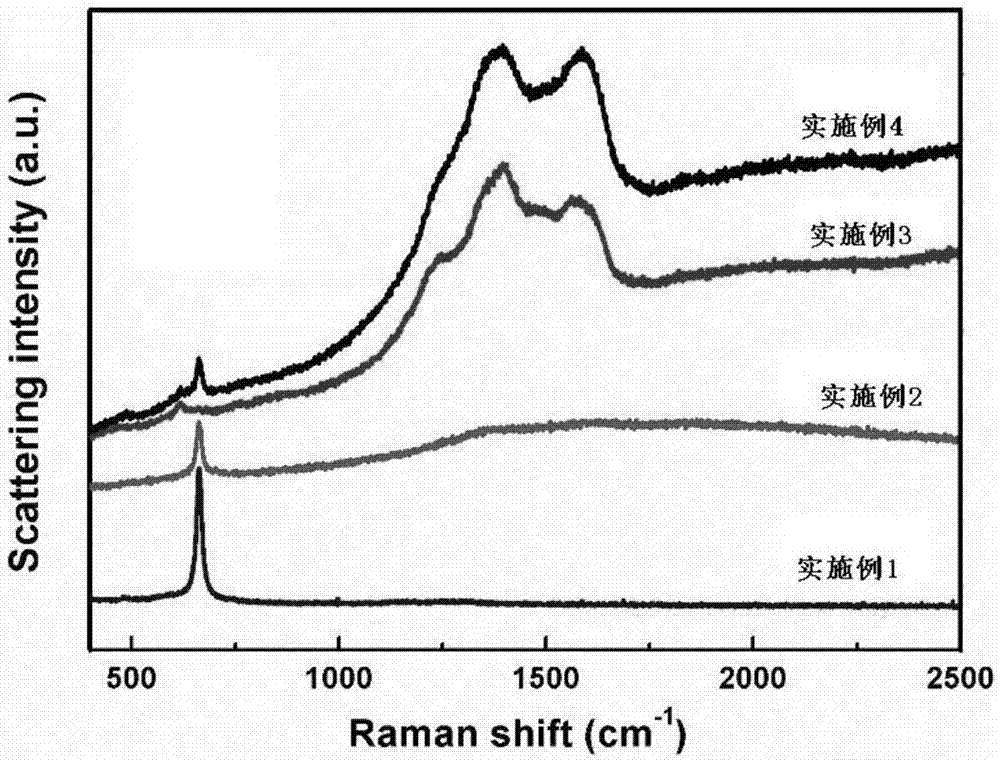

Embodiment 1

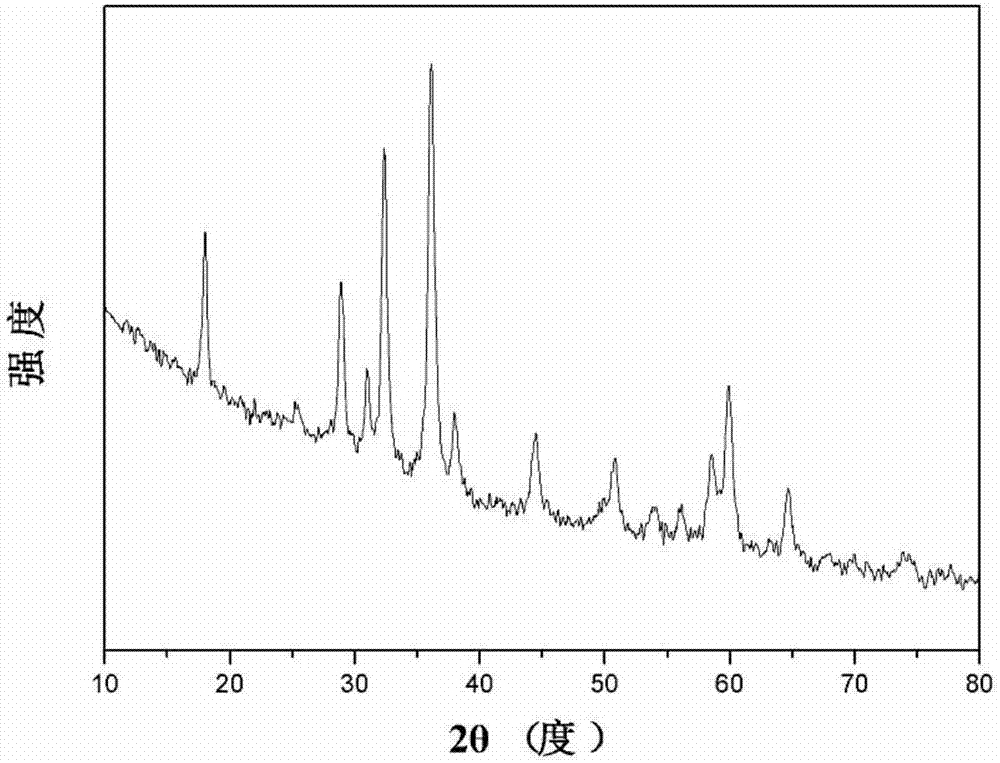

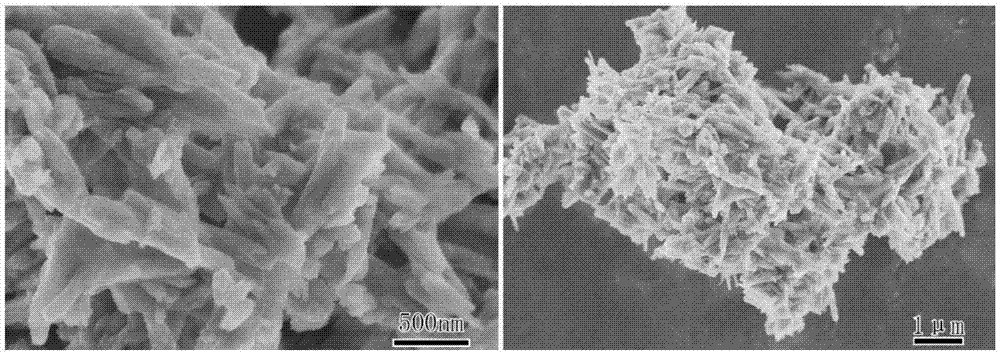

[0037] A method for preparing a manganese tetraoxide / carbon composite material with a rod-shaped core-shell structure for a negative electrode of a sodium ion battery, the specific steps are as follows:

[0038] (1) Dissolve 0.6040g of manganese sulfate and 0.9120g of ammonium persulfate in 40mL of deionized water, stir well to obtain solution R 1 , R 2 ;

[0039] (2) the two solutions R described in the above step (1) 1 , R 2 Mix and stir well to obtain a mixed solution R 3 ;

[0040] (3) the mixed solution R obtained in the above step (2) 3 Transfer to a hydrothermal reaction kettle with polytetrafluoroethylene lining, and keep the reaction at 140°C for 10h;

[0041] (4) naturally cool the reaction kettle of the above step (3) to room temperature to obtain black precipitated manganese dioxide; wash with deionized water and absolute ethanol several times and then dry in an oven at 70° C. overnight to obtain rod-shaped manganese dioxide;

[0042] (5) ultrasonically disp...

Embodiment 2

[0049] A method for preparing a manganese tetraoxide / carbon composite material with a rod-shaped core-shell structure for a negative electrode of a sodium ion battery, the specific steps are as follows:

[0050] (1) Dissolve 0.6795g of manganese carbonate and 1.0620g of ammonium persulfate in 40mL of deionized water respectively, and stir evenly to obtain solution R 1 , R 2 ;

[0051] (2) the two solutions R described in the above step (1) 1 , R 2 Mix and stir well to obtain a mixed solution R 3 ;

[0052] (3) the mixed solution R obtained in the above step (2) 3 Transfer to a hydrothermal reaction kettle with polytetrafluoroethylene lining, and keep the reaction at 130°C for 11h;

[0053] (4) naturally cool the reaction kettle of the above step (3) to room temperature to obtain black precipitated manganese dioxide; wash with deionized water and absolute ethanol several times and then dry in an oven at 70° C. overnight to obtain rod-shaped manganese dioxide;

[0054] (5...

Embodiment 3

[0061] A method for preparing a manganese tetraoxide / carbon composite material with a rod-shaped core-shell structure for the negative electrode material of a sodium ion battery, the specific steps are as follows:

[0062] (1) Dissolve 0.6795g of manganese carbonate and 1.0620g of ammonium persulfate in 40mL of deionized water respectively, and stir evenly to obtain solution R 1 , R 2 ;

[0063] (2) the two solutions R described in the above step (1) 1 , R 2 Mix and stir well to obtain a mixed solution R 3 ;

[0064] (3) the mixed solution R obtained in the above step (2) 3 Transfer to a hydrothermal reaction kettle with polytetrafluoroethylene lining, and keep the reaction at 150°C for 12h;

[0065] (4) naturally cool the reaction kettle of the above step (3) to room temperature to obtain black precipitated manganese dioxide; wash with deionized water and absolute ethanol several times and then dry in an oven at 70° C. overnight to obtain rod-shaped manganese dioxide; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com