Full-slot self-restoration frictional overrun clutch

An overrunning clutch and friction-type technology, which is applied in the field of mechanical transmission, can solve problems such as lack of bearing capacity and large contact stress, and achieve the effects of reducing manufacturing and assembly difficulty, small torque bearing capacity, and large radial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

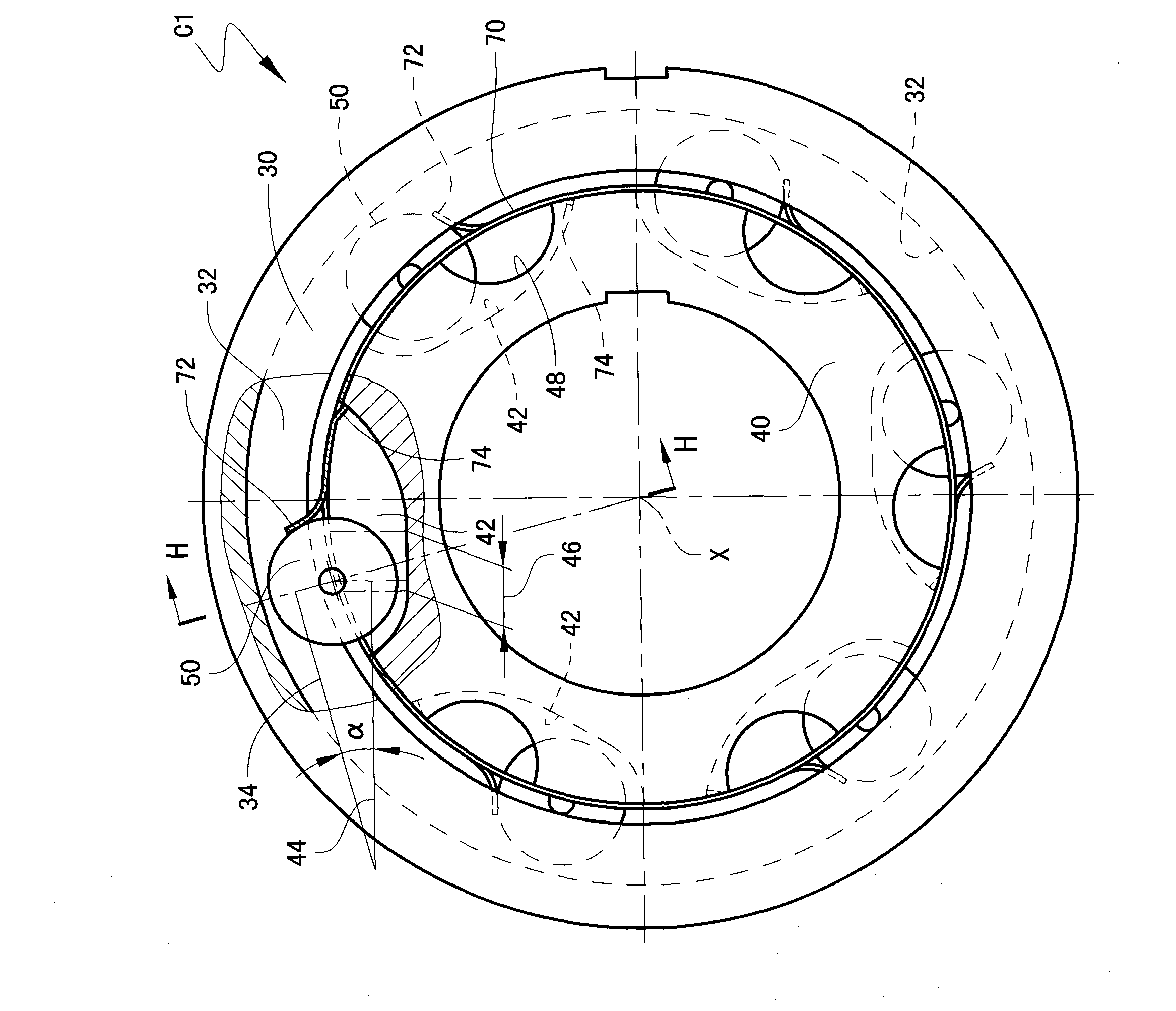

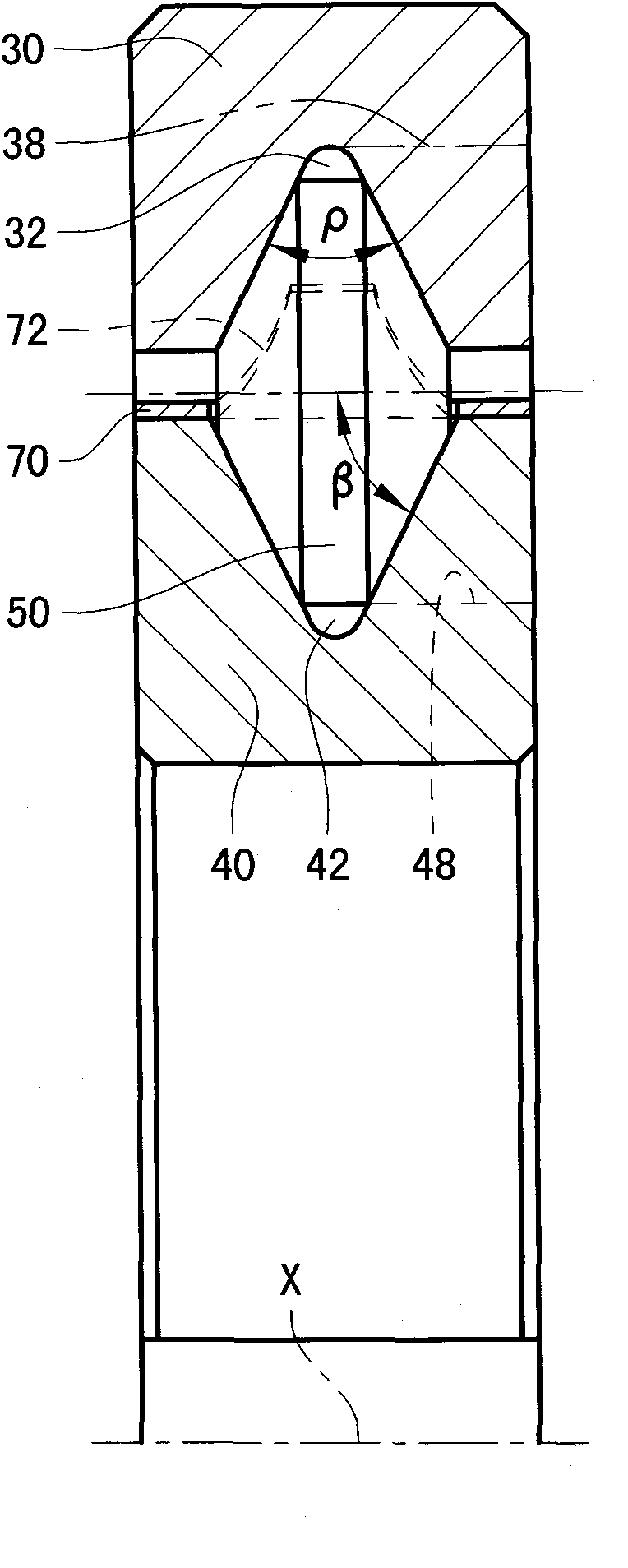

[0024] Embodiment 1: Full channel self-returning positive friction one-way overrunning clutch C1 with symmetrical double tapered rollers

[0025] Figure 1~2 , The clutch C1 shown in 8 belongs to the roller type overrunning clutch. Similar to most clutches of this type, it comprises an outer ring 30 revolving around the same axis X, an inner ring 40, as an intermediary a set of double tapered rollers 50 comprising at least one and an annular band spring 70 as a pretension spring .

[0026] Among them, for the convenience of manufacture, the symmetrical double-tapered roller 50 is used for the side surface of the frictional contact, and it is best to have two complete truncated conical rotary surfaces with two axially symmetrical semi-cone apex angles equal to β, and β = 90 degrees - ρ / 2. Wherein, ρ is the slope angle between the corresponding inner and outer grooves of the outer ring 30 and the inner ring 40 in the axial plane. In order to reduce no-load resistance and wea...

Embodiment 2

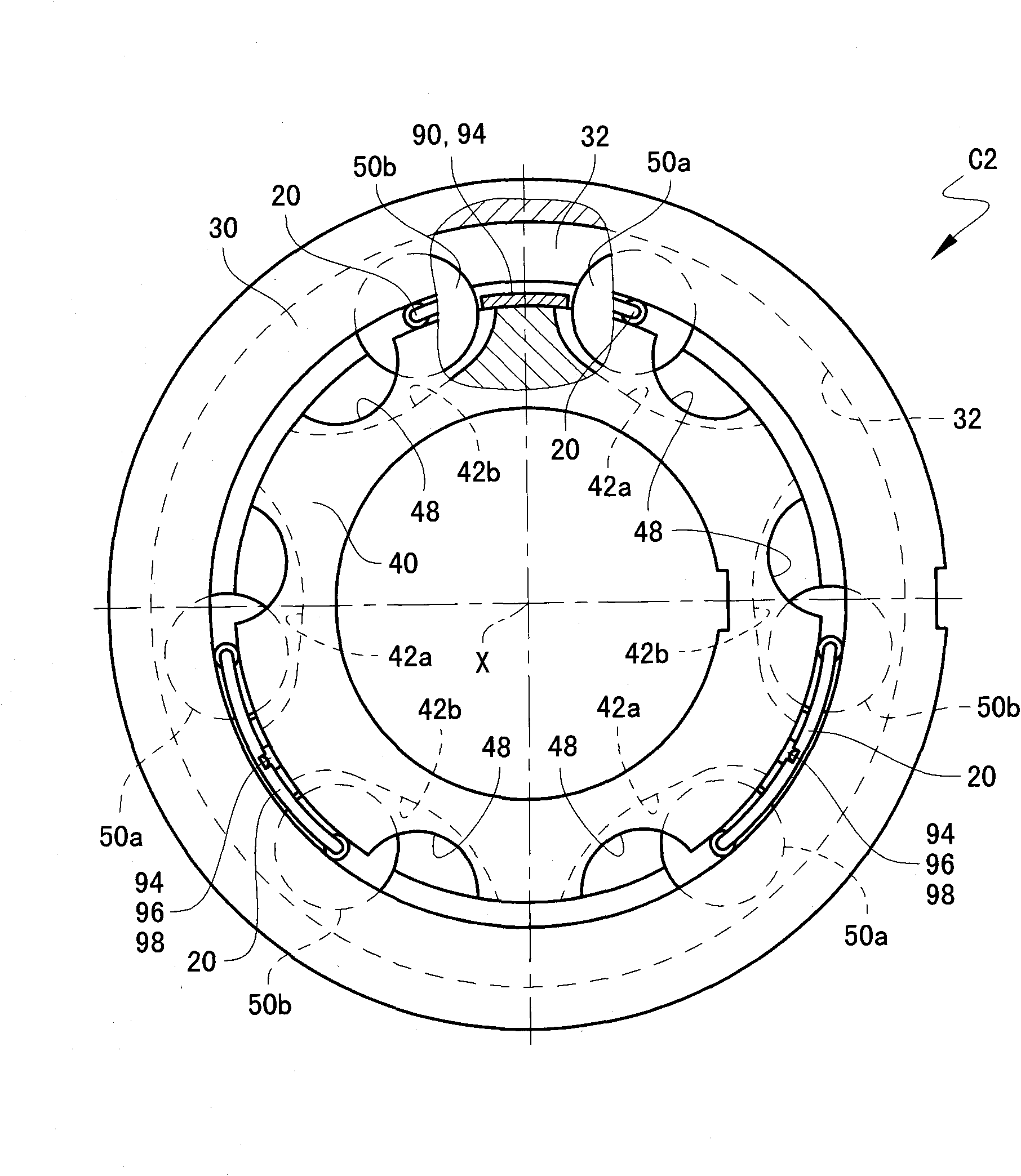

[0044] Embodiment 2: Full channel self-returning positive friction type two-way overrunning clutch C2 with the same rotary surface

[0045] In fact, if Figure 3A-3B , The clutch C2 shown in 9A~9B is only an improved application of the clutch C1 in the first embodiment, and like the clutch C1, the clutch C2 also belongs to the roller type overrunning clutch, and has the existing technology The full functionality of the so-called two-way overrunning clutch with detents.

[0046] Wherein, instead of the wire-shaped bow spring 20 of the annular belt spring 70, it is best made of a spring steel wire, see Figures 9A-9B , the radius of curvature of the arc segment 22 in the planar space of gyration is preferably smaller than the radius of gyration of the circle of gyration where the centerlines of curvature of the double-tapered rollers 50a and 50b are located. In order to increase its elasticity and extend in the circumferential direction, the arc segment 22 is deliberately made...

Embodiment 3

[0055] Embodiment 3: Full-channel self-returning positive friction double-way overrunning clutch C3 with different rotary surfaces

[0056] see Figure 4~5 , same as the clutch C2, the two-way overrunning clutch C3 is still a duplex of two one-way overrunning clutches C1 with opposite working directions, the only difference is that the former is a duplex of two identical clutches C1 in the same planar slewing space, The latter is a rigid duplex of two identical clutches C1 in different plane-type slewing spaces, so as to have a load-carrying capacity completely equivalent to that of the one-way clutch C1.

[0057] Wherein, two sets of oppositely facing outer grooves 42a and 42b are arranged at approximately corresponding circumferential positions, and each set of notches 48a and 48b have exactly the same circumferential and radial positions corresponding to each other, and are located at The axially same end of the outer channel 42a or 42b, such as Figure 5 shown on the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com