Radial tire segmented mold capable of evenly vulcanizing tire crown

A radial tire and tire crown technology, applied in the field of vulcanization molds, can solve problems such as uneven vulcanization of radial tire crowns, and achieve the effect of improving performance quality and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

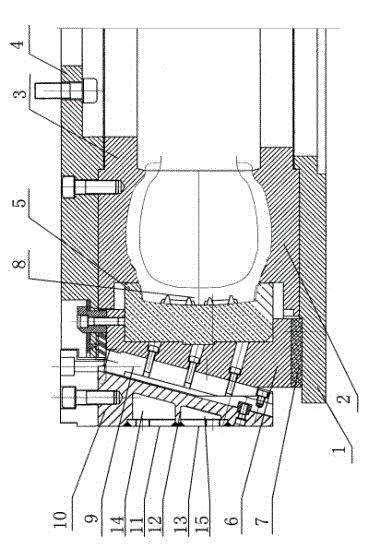

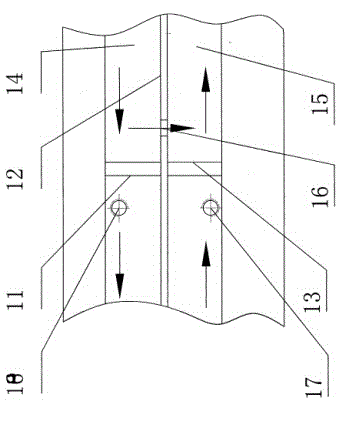

[0010] The present invention is described in detail below in conjunction with accompanying drawing:

[0011] A radial tire flexible mold capable of uniformly vulcanizing the crown, comprising an annular base 1, an annular lower side plate 2, an annular upper side plate 3 and an annular upper cover 4, and an annular lower side plate 2 is arranged on the annular base 1 , an annular upper side plate 3 is arranged on the lower bottom surface of the annular upper cover 4, an annular base wear-resistant plate 7 is arranged on the annular base 1 outside the annular lower side plate 2, and an annular base wear plate 7 is arranged on the outer lower bottom surface of the annular upper cover 4. An annular upper cover wear plate is arranged on the top, a crown pattern arch seat 6 is arranged between the annular base wear plate 7 and the annular upper cover wear plate, and a crown pattern mold is arranged inside the crown pattern arch seat 6 5. A radial tire 8 is arranged between the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com