A fuel tank mold

A fuel tank mold and mold body technology, which is applied in the field of fuel tank molds, can solve the problems of deformation connection strength and air tightness, easy deformation of the fuel tank body shape, and increased cost of finished products, so as to improve the yield of finished products, prevent large-scale deviation, and use The effect of material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

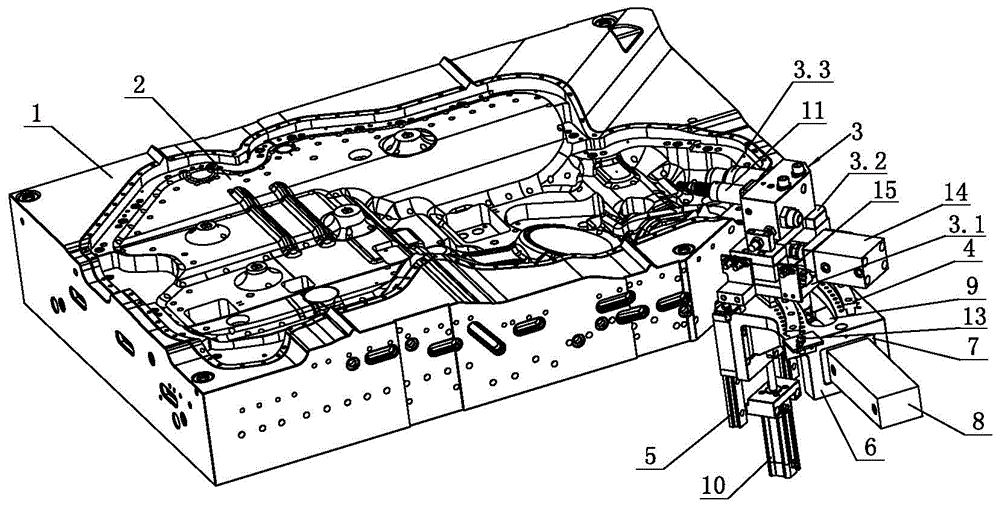

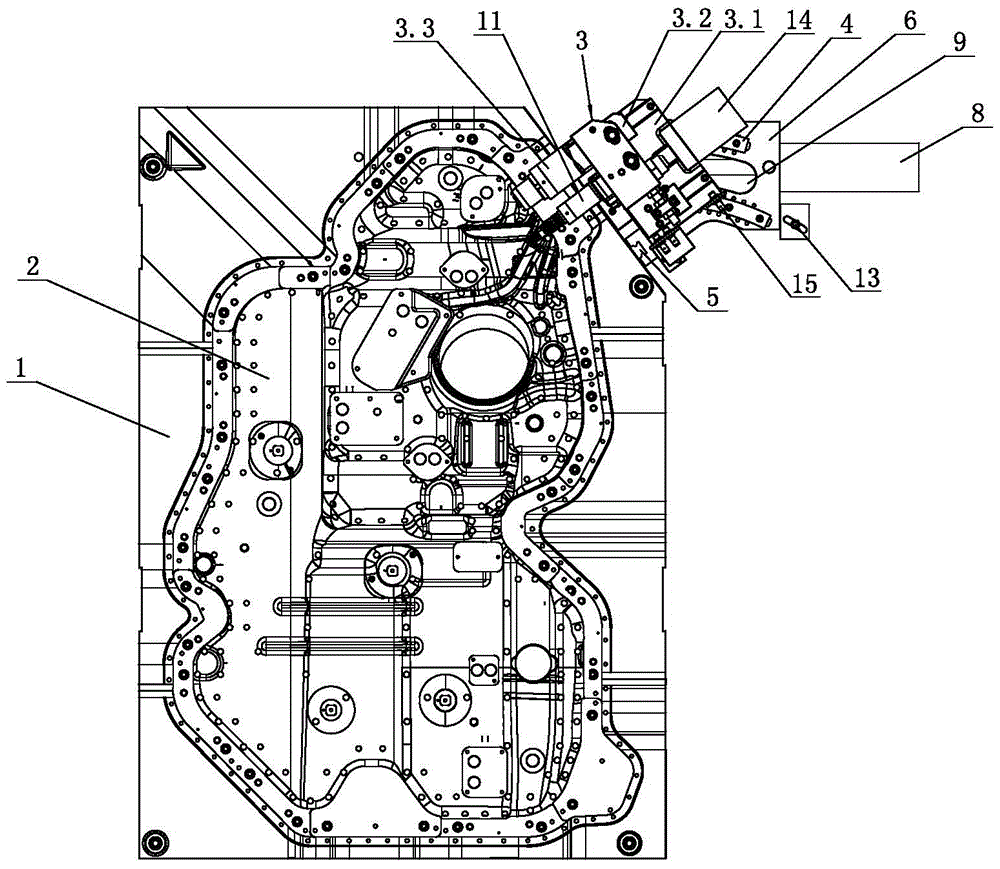

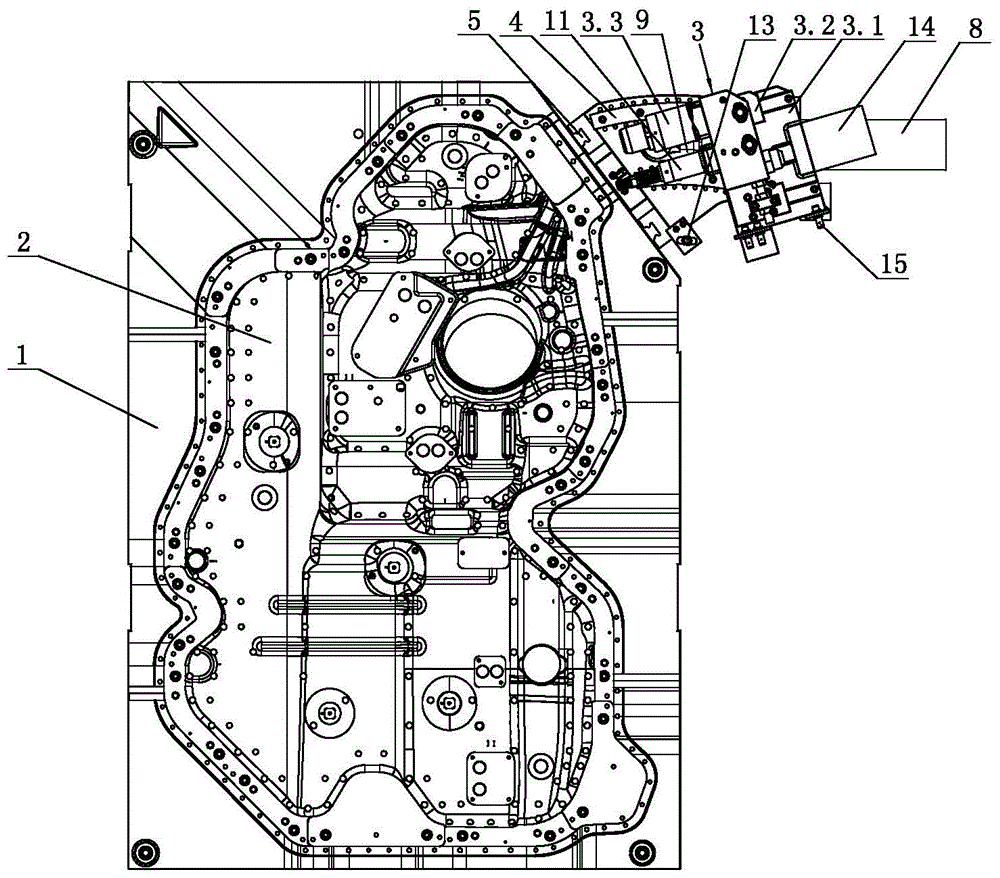

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Shown, a kind of fuel tank mould, it comprises the mold body 1 on the mold base (the mold base is not shown in the accompanying drawing) and the mold cavity 2 on the mold body 1 (of course also includes other components, but because it does not involve this Invention point of the invention, so it will not be repeated here), the mold body 1 is provided with a needle blowing mechanism 3, and the needle blowing mechanism 3 is located at the upper end of the mold body 1, and the upper end of the mold cavity 2 The maximum width is smaller than the maximum width of the lower end of the cavity 2, that is, the relatively small end of the fuel tank body is located at the top, while the relatively large end of the fuel tank body is located at the bottom, and the upper end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com