Fuel tank die

A fuel tank mold and fuel tank technology, applied in the field of fuel tank moulds, can solve the problems of easy deformation of the fuel tank body, increased cost of the fuel tank, uneven shrinkage of the fuel tank, etc., and achieve the effects of not being easy to deviate in a large range, increasing the yield, and facilitating water-cooling and shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

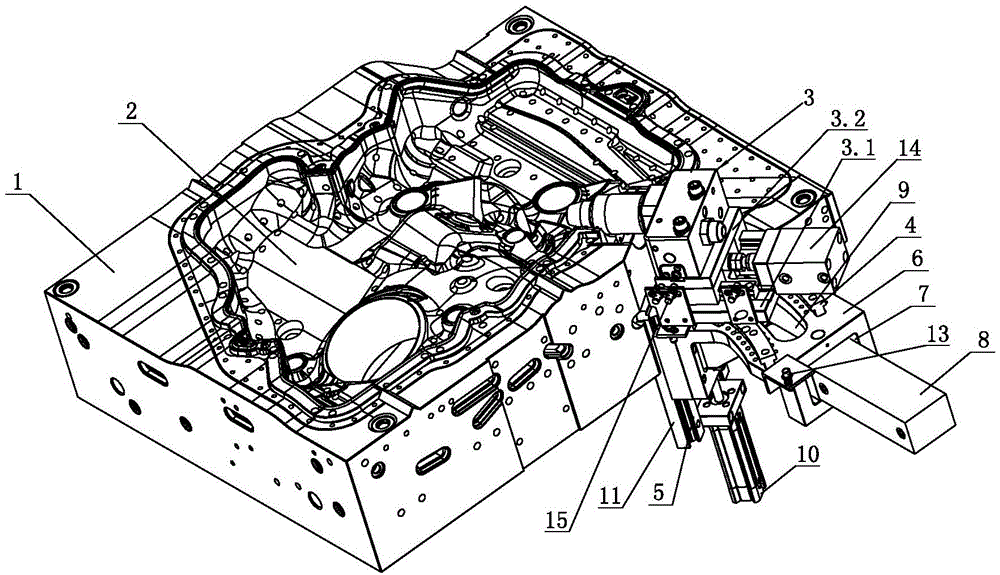

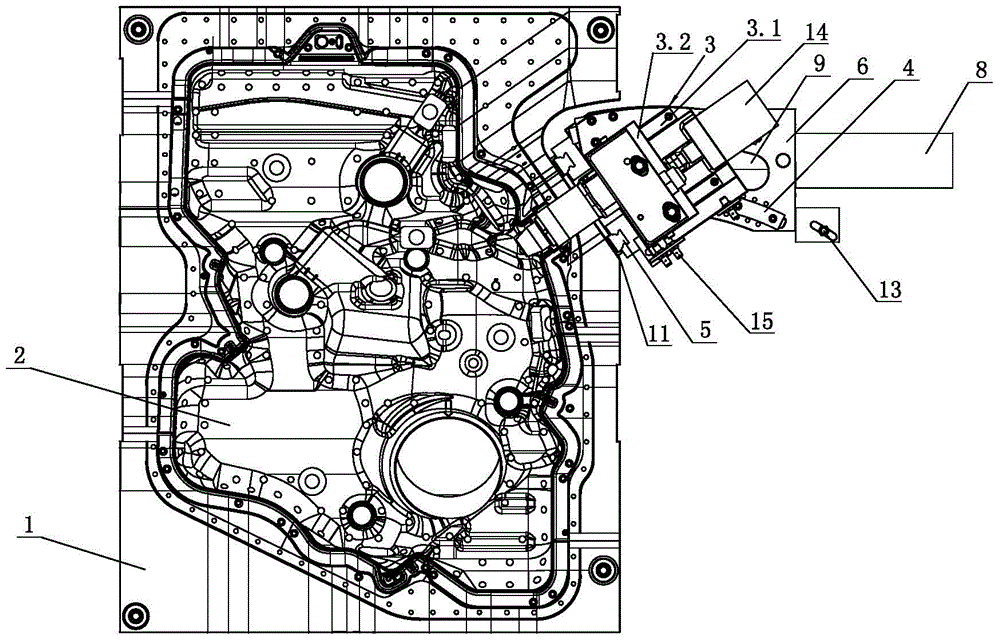

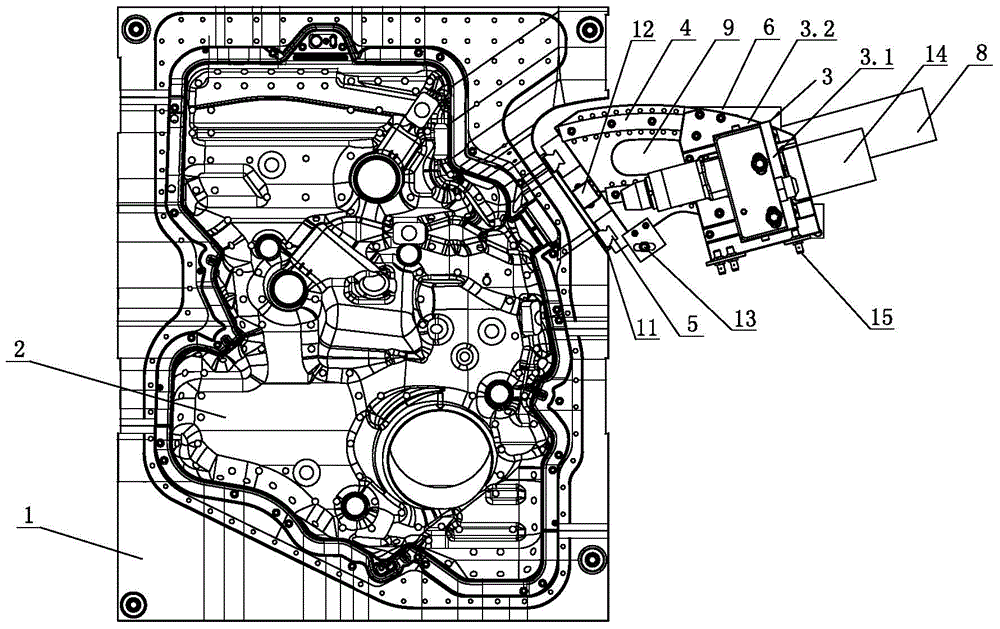

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown, a kind of fuel tank mould, it comprises mold body 1 and the mold cavity 2 on mold body 1 (certainly also comprises other parts, but because do not relate to the invention point that the present invention creates, so do not repeat them here), so The mold body 1 is provided with a needle blowing mechanism 3, the needle blowing mechanism 3 is located at the upper end of the mold body 1, and the maximum width of the upper end of the cavity 2 is smaller than the maximum width of the lower end of the cavity 2, that is, the fuel tank body The relatively smaller end is located above, while the relatively larger end of the fuel tank is located below. The upper end of the mold body 1 is provided with an arc track 4 and a linear guide rail 5, and the blowing needle mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com