A kind of raising drilling machine construction method

A technology for raising drilling rigs and construction methods, which is applied to drilling equipment and methods, drilling equipment, earthwork drilling, etc., and can solve the problem of removing drill bits, clogging the inner wall of drill pipes, and easily wrapping drill bits and drill pipes in muddy rock and soil, etc. problems, to achieve the effect of ensuring excavation accuracy, improving installation efficiency, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

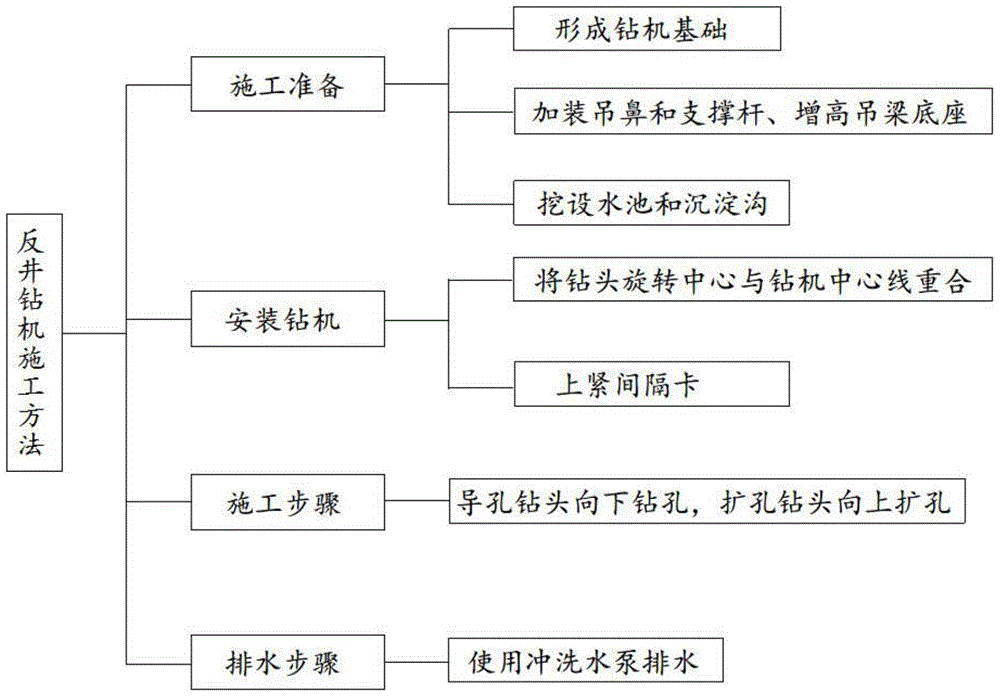

[0030] Such as figure 1 As shown, the present invention provides a construction method of a raise rig, including construction preparation, installation of the rig and construction steps,

[0031] The construction preparation steps include:

[0032] 1) Forming the foundation of the drilling rig: After the first phase of concrete pouring is carried out with the drilling as the center, the main machine track is laid on the concrete platform, and anchor nets are used on both sides of the main machine track, and 30B I-beam is used to strengthen the base at the bottom of the main machine track Intensity, the raise rig main engine is transported to the main engine track and leveled in sequence, and the second-stage concrete pouring is carried out to form the drilling rig foundation. Among them, the raise rig main engine is transported to the main engine track in sequence, and the transportation sequence is: drill pipe car, drilling rig car, pump Vehicles, fuel tank vehicles and other mai...

Embodiment 2

[0046] Such as figure 1 As shown, the present invention provides a construction method of a raise rig, including construction preparation, installation of the rig and construction steps,

[0047] The construction preparation steps include:

[0048] 1) Forming the foundation of the drilling rig: After the first phase of concrete pouring is carried out with the drilling as the center, the main machine track is laid on the concrete platform, and anchor nets are used on both sides of the main machine track, and 30B I-beam is used to strengthen the base at the bottom of the main machine track Intensity, the main engine of the raise rig is transported to the main engine track in turn and leveled, and the second-stage concrete pouring is carried out to form the drilling rig foundation. Among them, the main engine of the raise rig is transported to the main engine track in turn. When the construction site is less than 3-5m from the front, the transportation The sequence is: drill pipe tru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com