Hub cleaning device

A cleaning device and hub technology, applied in the field of cleaning, can solve the problems of long drying time and insufficient flushing of the hub, and achieve the effect of improving the processing progress, no overlapping dead angle, and reducing the drying time of the hub

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

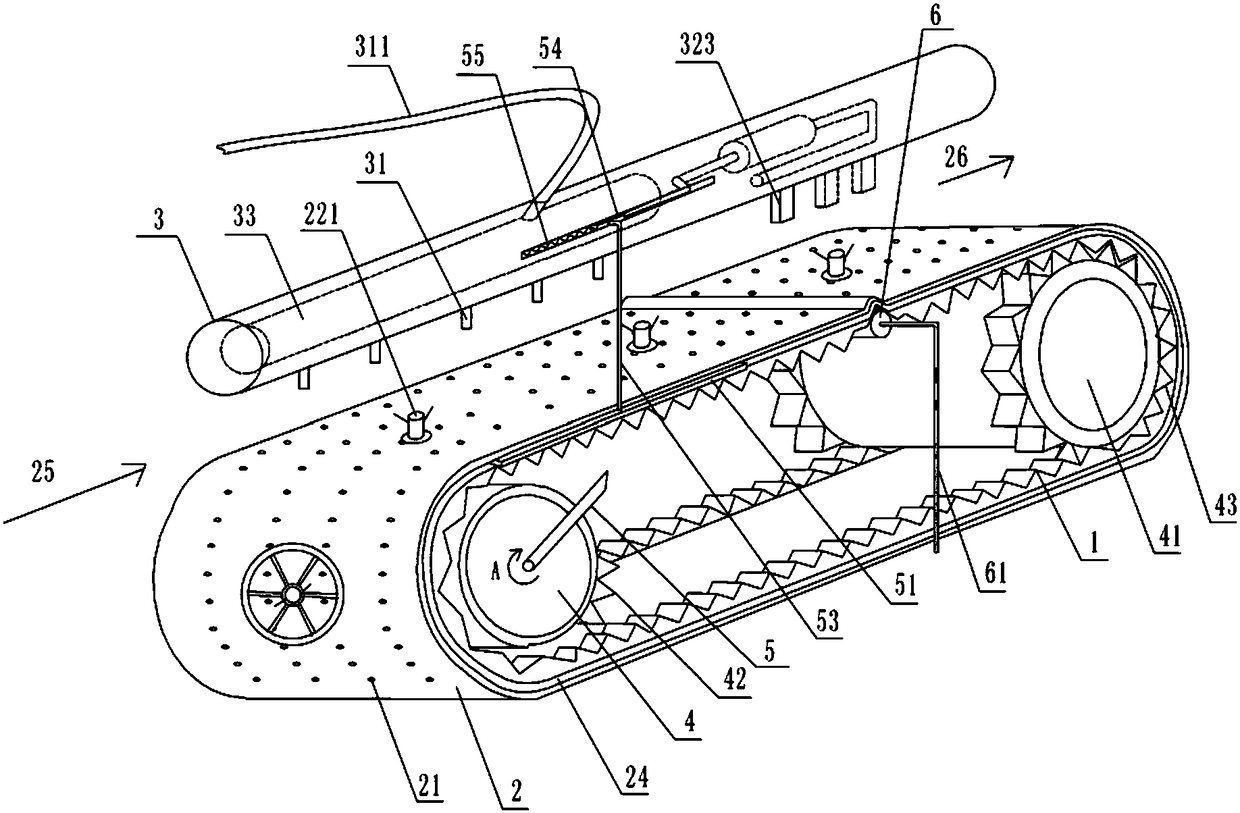

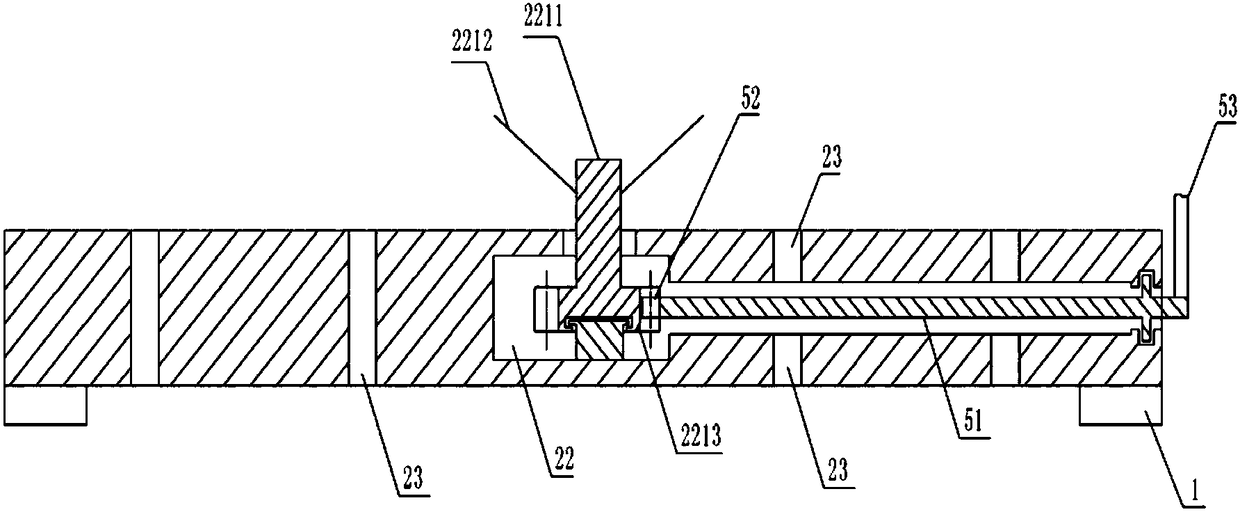

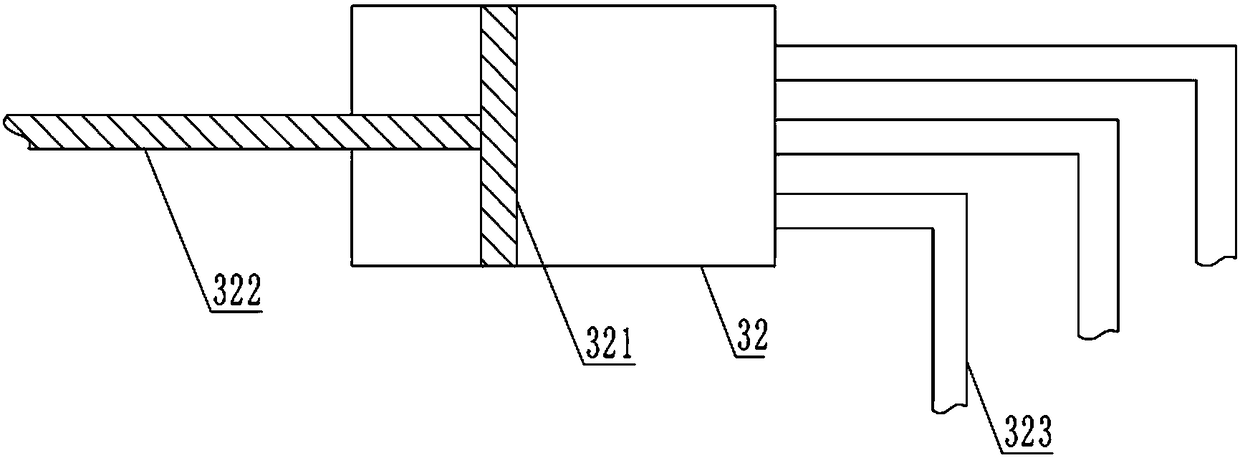

[0023] The reference numerals in the accompanying drawings of the description include: conveyor chain 1, conveyor belt 2, water leakage hole 21, cavity 22, rotating rod 221, rotating rod body 2211, inclined rod 2212, ring gear 2213, through hole 23, opening 24, Feed end 25, discharge end 26, cleaning part 3, spray head 31, water inlet pipe 311, air cylinder 32, piston 321, piston rod 322, air blowing pipe 323, water chamber 33, driving wheel 4, driven wheel 41, not Complete gear 42, driven gear 43, power rod 5, first slide block 51, rack 52, connecting rod 53, second slide block 54, return spring 55, transition shaft 6, fixed rod 61.

[0024] Such as figure 1 , figure 2 and image 3 Shown, in order to achieve the above object, basic scheme of the present invention is as follows:

[0025] The hub cleaning device includes a conveyor chain 1, a conveyor belt 2, a cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com