Full-automatic filter element flushing machine

A washing machine, fully automatic technology, applied in the field of polyester equipment, can solve the problems of difficult to guarantee the quality of washing, the decline of filtration performance, and the labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

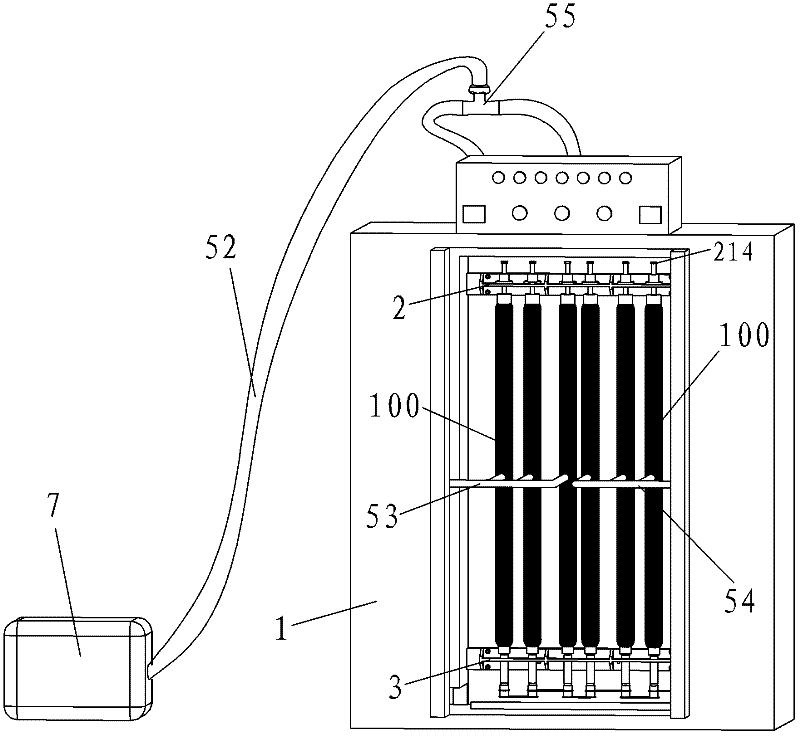

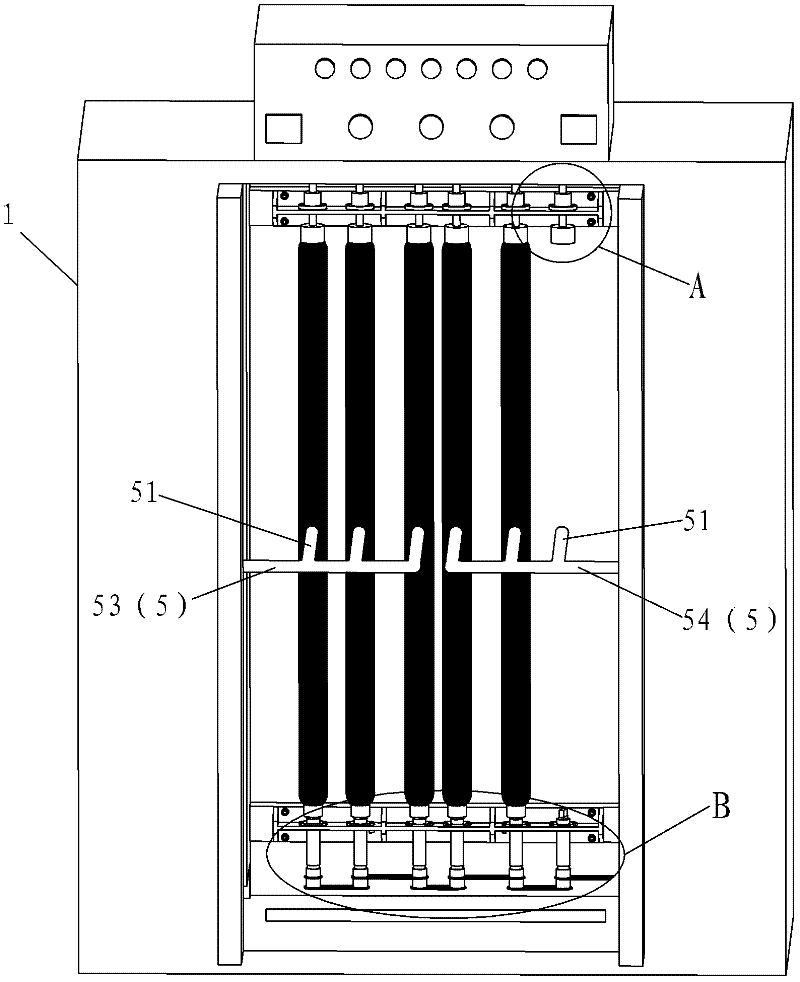

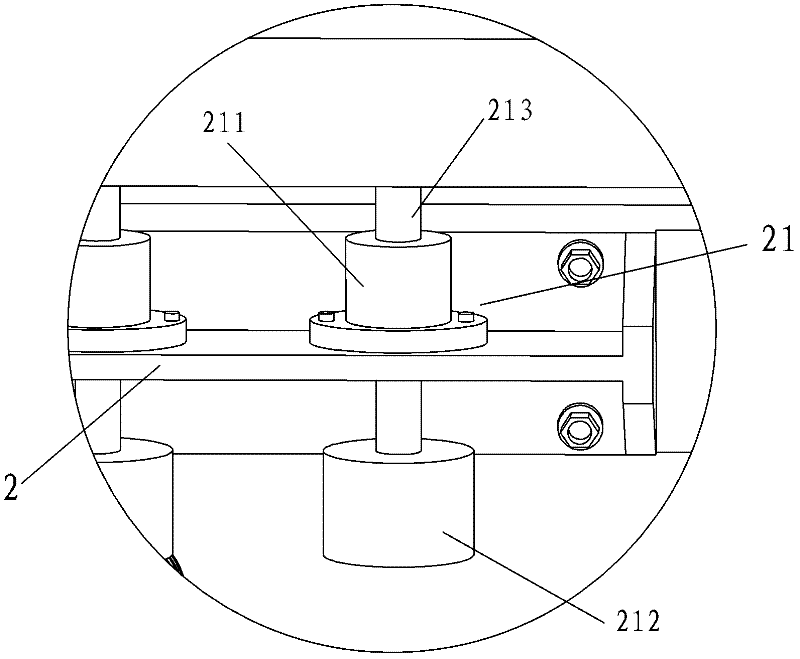

[0042] A kind of full-automatic filter element flushing machine of the present invention, take can flush 6 filter elements 100 as an example, as Figure 1-6As shown, including the casing 1 and the upper mounting frame 2 and the lower mounting frame 3 located in the casing 1, the upper mounting frame 2 is provided with an upper mounting seat 21 for the upper end of the filter element 100 to be installed on the upper mounting frame 2, This upper mounting base 21 is provided with 6 pieces, and each upper mounting base 21 comprises fixing block 211, mounting block 212 and connecting rod 213 respectively, and fixing block 211 is locked on the upper surface of upper mounting frame 2 by bolts, and mounting block 212 sets Below the lower bottom surface of the upper mounting frame 2, and the lower bottom surface of the mounting block 212 is provided with a fixing hole (not shown) for the upper end of the filter element 100 to be tightly fitted and fixed therein, and the connecting rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com