Real-time measuring system for changes of an electric potential on the surface of an insulating material

A surface potential and insulating material technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of large measurement time interval constant, different experimental conclusions, and the inability to capture the continuous change characteristics of local area potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The system for measuring the surface potential change characteristics of insulating materials proposed by the present invention is described as follows in conjunction with the accompanying drawings and embodiments:

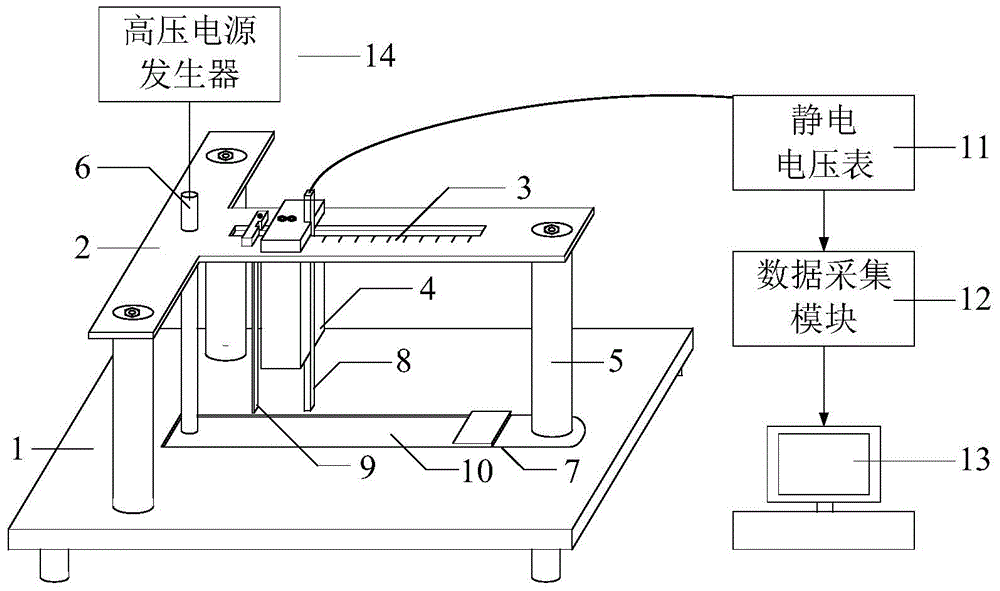

[0012] The structure of the embodiment of the system for measuring the surface potential change characteristics of insulating materials of the present invention is as follows: figure 1 As shown, it includes a base 1, a fixed bracket 2 for probes and electrodes, a sliding guide rail 3 with a ruler, a probe holder 4, a support column 5, a high-voltage electrode 6, a ground electrode 7, a capacitance probe 8, and a probe protective cover 9, The insulating material fixing groove 10, the electrostatic voltmeter 11, the data acquisition module 12, the data processing system and the display interface 13, and the high-voltage power generator 14; wherein, the fixing bracket 2 of the probe and the electrode is fixed above the base 1 through the support column 5, The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com