Touch screen and manufacturing method thereof and touch display device

A touch screen and touch sensor technology, applied in the fields of touch screen and its manufacture, and touch display device, can solve the problem that users cannot see the touch screen information clearly, and achieve the effect of mature production process, improved effect and improved contrast ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

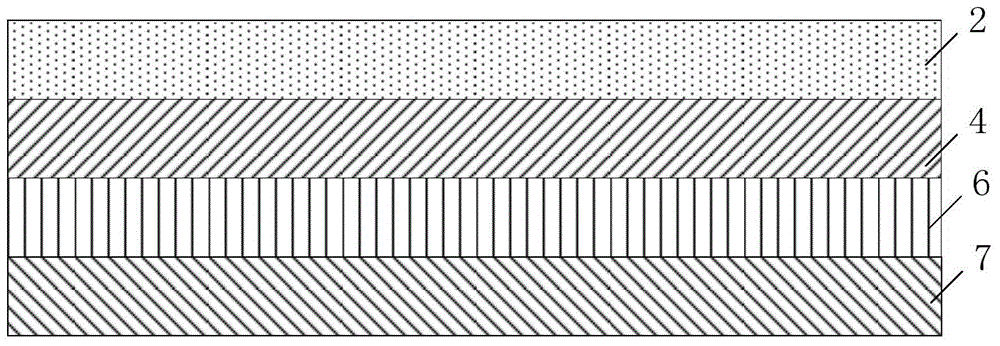

[0058] Embodiment 1 of the present invention firstly provides a touch screen, see figure 1 , which in turn includes:

[0059] Polarizing film 2, used to polarize incident light and transmit a component perpendicular to the touch screen;

[0060] The λ / 4 wave plate 4 is used to cause the incident light to produce a phase delay of λ / 4, it should be understood that here λ is the wavelength of the incident light;

[0061] polymer film 6; and

[0062] touch sensor7.

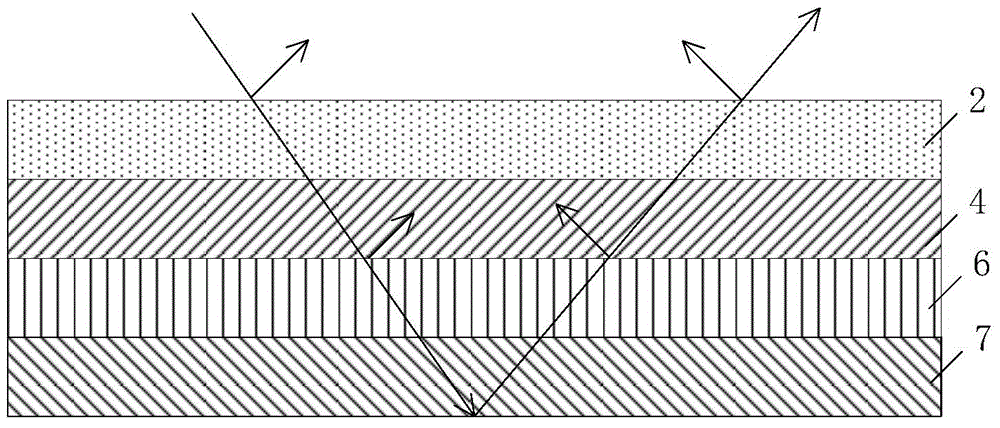

[0063] Among them, the combination of the polarizing film 2 and the 1 / 4 lambda wave plate (retardation film) 4 helps to reduce the reflection of ambient light and improve the use effect. figure 2 It is a schematic diagram of the reflection light path of the touch screen according to the embodiment of the present invention. The polarizing film 2 can be a polyvinyl alcohol PVA polarizing film, which is made of a PVA film layer after being dyed and stretched. The polarizing film 2 is the main part that forms polariz...

Embodiment 2

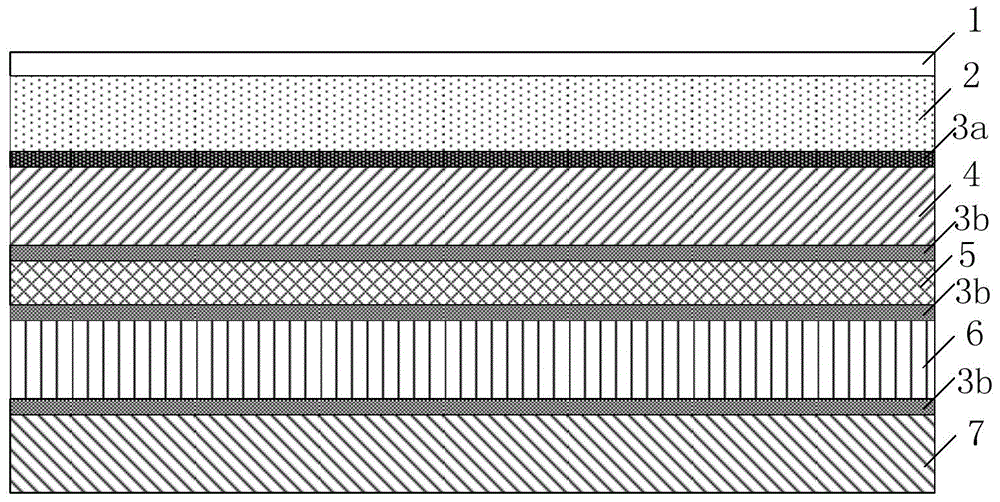

[0066] Embodiment 2 of the present invention is prepared on the basis of the touch screen shown in Embodiment 1 of the present invention, as image 3As shown, the surface of the polarizing film 2 may further include: a protective film 1 for anti-glare, anti-reflection and / or anti-static. The protective film 1 can be an anti-reflection triacetate protective film, and the TAC film layer with good optical uniformity and transparency is used to isolate moisture and air, so as to prevent the polarizing film 2 from losing its polarizing performance due to water absorption and fading, and at the same time, the protective film 1 can be protected. Treatments such as glare, anti-reflection, UV protection and / or antistatic coatings become functional protective films.

[0067] Optionally, between the λ / 4 wave plate 4 and the polymer film 6 may also include: a semi-transparent and semi-reflective metal shielding film 5, which may be a gold-plated film, a silver-plated film, an aluminum-pla...

Embodiment 3

[0072] Embodiment 3 of the present invention provides a touch display device, which includes a display screen and the touch screen as described in any one of the above items, wherein the touch screen is adhered to the display screen.

[0073] Optionally, the display screen may be an AMOLED display module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com